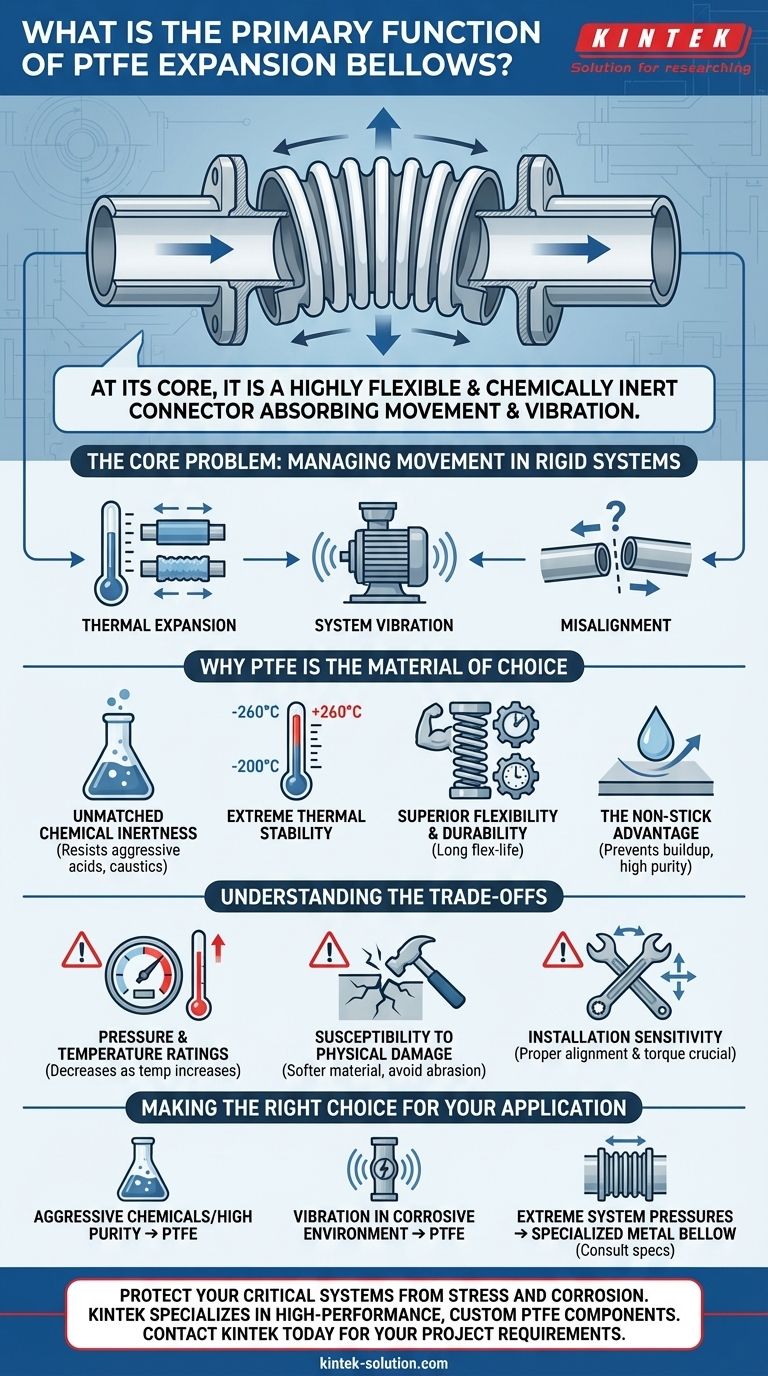

At its core, the primary function of a PTFE expansion bellow is to serve as a highly flexible and chemically inert connector in a piping or ducting system. It is specifically designed to absorb movement and vibration between two points, safely accommodating thermal expansion, contraction, and mechanical stress while isolating the fluid flow.

While many components can connect pipes, a PTFE expansion bellow is fundamentally a problem-solver for dynamic systems. It is chosen specifically for its unique material properties that protect critical equipment from stress in corrosive, high-purity, or extreme temperature environments.

The Core Problem: Managing Movement in Rigid Systems

Piping and vessel systems are rarely static. They are subject to constant forces that can cause stress, fatigue, and eventual failure if not properly managed. Bellows are engineered to be the point of absorption for these forces.

The Inevitability of Thermal Expansion

As process temperatures fluctuate, pipe materials expand and contract. Over long runs, this movement can be significant, exerting immense force on fixed points like nozzles and pumps.

The Challenge of System Vibration

Mechanical equipment such as pumps, compressors, and motors introduce persistent vibration into a system. PTFE bellows effectively dampen this vibration, isolating sensitive instruments and preventing fatigue cracks in the pipework.

The Impact of Misalignment

No installation is perfect. Bellows can compensate for minor initial pipe misalignment, reducing the stress that would otherwise be locked into the system from the start.

Why PTFE is the Material of Choice

The selection of Polytetrafluoroethylene (PTFE) is not arbitrary. Its distinct properties make it uniquely suited for the most demanding applications where other materials would quickly fail.

Unmatched Chemical Inertness

PTFE is virtually inert to almost all industrial chemicals and solvents. This makes it the default choice for systems handling aggressive acids, caustics, or other corrosive media that would destroy metal or rubber bellows.

Extreme Thermal Stability

PTFE maintains its properties across a very wide operating temperature range. This allows it to perform reliably in applications involving both cryogenic fluids and high-temperature processes.

Superior Flexibility and Durability

A key function of a bellow is to flex repeatedly without failure. PTFE offers excellent flex-life, allowing it to absorb movement and vibration over thousands of cycles without compromising its structural integrity.

The Non-Stick Advantage

The surface of PTFE is non-adhesive and has an extremely low coefficient of friction. This prevents process media from sticking or building up inside the bellow, which is critical for purity in pharmaceutical and food applications and for preventing clogs in slurry systems.

Understanding the Trade-offs

While highly effective, PTFE bellows are not a universal solution. Understanding their limitations is key to successful application.

Pressure and Temperature Ratings

PTFE's primary trade-off is its pressure-handling capability, which decreases as temperature increases. In very high-pressure applications, a metal expansion joint may be a more appropriate choice, though it sacrifices chemical resistance.

Susceptibility to Physical Damage

Compared to steel, PTFE is a softer material. Care must be taken during installation and operation to protect the bellow from external abrasion, impact, or puncture.

Installation Sensitivity

The performance of a PTFE bellow is highly dependent on proper installation. Incorrect alignment or improper bolt torque on the flanges can damage the sealing surface and lead to premature failure.

Making the Right Choice for Your Application

Selecting the correct component requires aligning its strengths with your primary operational goal.

- If your primary focus is handling aggressive chemicals or high-purity media: PTFE is the definitive choice due to its chemical inertness and non-stick surface, which prevents contamination and corrosion.

- If your primary focus is absorbing vibration in a corrosive environment: The combination of flexibility and chemical resistance makes PTFE a superior solution to both rigid piping and standard elastomers.

- If your primary focus is managing extreme system pressures: You must carefully consult the manufacturer's specifications, as a specialized metal bellow may be required for the highest-pressure applications.

Ultimately, selecting a PTFE expansion bellow is a strategic decision to ensure the integrity, reliability, and longevity of your most demanding systems.

Summary Table:

| Function | Key Benefit of PTFE |

|---|---|

| Absorb Thermal Expansion/Contraction | Extreme thermal stability (-200°C to +260°C) |

| Dampen Vibration | Superior flexibility and durability for long flex-life |

| Compensate for Misalignment | Reduces stress on pumps, nozzles, and fixed points |

| Contain Corrosive Media | Unmatched chemical inertness to acids, caustics, and solvents |

| Maintain Purity | Non-stick, non-contaminating surface prevents buildup |

Protect your critical systems from stress and corrosion.

Does your application in the semiconductor, pharmaceutical, laboratory, or industrial sector involve aggressive chemicals, high purity requirements, or significant temperature swings? KINTEK specializes in manufacturing high-performance, custom PTFE components, including expansion bellows, designed to solve these exact challenges.

We prioritize precision production and offer custom fabrication from prototypes to high-volume orders, ensuring a perfect fit and reliable performance for your specific needs.

Contact KINTEK today to discuss your project requirements and discover how our PTFE solutions can enhance the integrity and longevity of your systems.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the two types of piston seals? Single-Acting vs. Double-Acting Explained

- What are some other miscellaneous uses of Teflon? From Aerospace to Medical Devices

- What are the installation and maintenance guidelines for Teflon bearings? Maximize Lifespan and Performance

- What are the key properties of PTFE envelope gaskets? Ensure Reliable Sealing in Demanding Environments

- What factors should be considered when choosing a gasket material? A Guide to Reliable Sealing

- How do fillers enhance PTFE's properties? Unlock Superior Wear Resistance & Stability

- How does PTFE compare to other fluoropolymers in chemical resistance? Discover the Benchmark for Chemical Inertness

- How often should torque settings on bolts be checked in PTFE butterfly valves? Prevent Leaks with Proper PTFE Maintenance