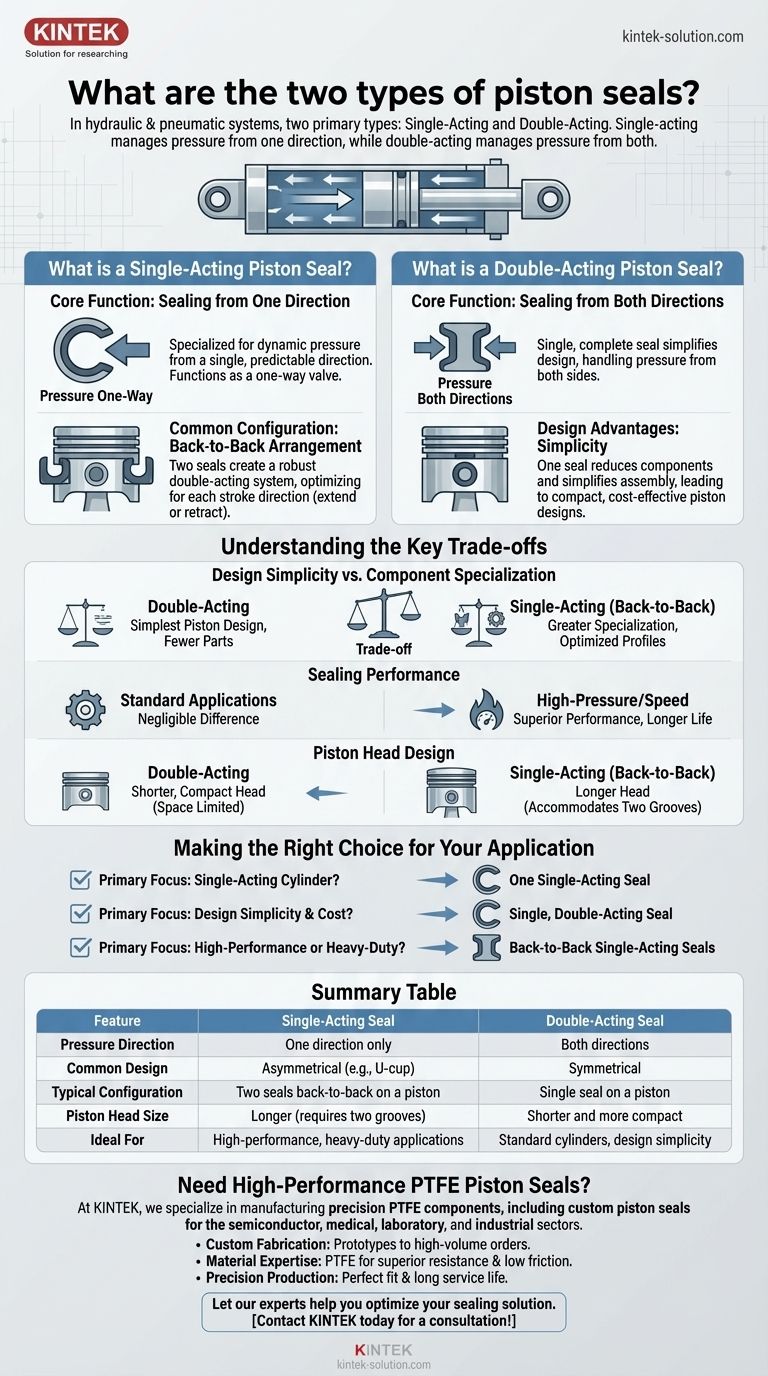

In any hydraulic or pneumatic system, the two primary types of piston seals are single-acting and double-acting. A single-acting seal is designed to manage pressure from only one direction, while a double-acting seal is engineered to manage pressure from both directions within a cylinder.

The fundamental difference lies in their application: choose a single-acting seal for one-way pressure control, and a double-acting seal for a simplified, all-in-one solution to manage bidirectional pressure.

What is a Single-Acting Piston Seal?

A single-acting seal is a specialized component optimized for sealing dynamic pressure from a single, predictable direction. It is the fundamental building block for many sealing systems.

Core Function: Sealing from One Direction

Think of a single-acting seal as a one-way valve for pressure. Its asymmetrical design, often a U-cup or lip seal, is specifically shaped to engage and seal effectively when force is applied from one side.

When pressure comes from the opposite, non-sealing direction, the seal's lip is designed to be pushed away, preventing pressure traps between seals.

Common Configurations

Because they only seal in one direction, two single-acting seals are often used in a back-to-back arrangement on a piston. This creates a robust double-acting system where each seal handles pressure during its respective stroke direction (extend or retract).

This configuration is common in heavy-duty or high-performance applications where optimizing the seal profile for each direction is critical.

What is a Double-Acting Piston Seal?

A double-acting piston seal is a single, complete seal designed to handle pressure from both directions. It simplifies the piston design by combining two functions into one component.

Core Function: Sealing from Both Directions

This type of seal is symmetrical. Its design allows it to activate and create a seal regardless of which side of the piston is pressurized.

This makes it an ideal solution for standard double-acting cylinders where the piston must extend and retract under power.

Design Advantages

The primary advantage is simplicity. Using one double-acting seal reduces the number of components on the piston head and simplifies the machining and assembly process.

This often leads to a more compact and cost-effective piston design compared to a system requiring two separate single-acting seals.

Understanding the Key Trade-offs

Choosing between these seal types involves a direct trade-off between design simplicity and component specialization. Your application's performance requirements and manufacturing constraints will guide the decision.

Design Simplicity vs. Component Specialization

A single double-acting seal offers the simplest piston design. It requires fewer grooves to be machined and fewer parts to be installed, reducing complexity and potential points of failure.

Using two single-acting seals allows for greater specialization. You can use different materials or profiles for each seal to optimize for different pressures or speeds on the extend and retract strokes.

Sealing Performance

In many standard applications, the performance difference is negligible. However, in high-pressure or high-speed systems, a back-to-back arrangement of single-acting seals can offer superior performance and a longer service life.

This is because each seal is perfectly optimized for its one job, leading to better lubrication, less friction, and more reliable sealing under demanding conditions.

Piston Head Design

The choice directly impacts the physical size of the piston head. A single double-acting seal allows for a shorter piston head, which can be critical in applications where space is limited.

A back-to-back arrangement of single-acting seals requires a longer piston head to accommodate the two separate grooves needed for the seals.

Making the Right Choice for Your Application

The correct seal is the one that best aligns with the operational demands and design constraints of your cylinder.

- If your primary focus is a single-acting cylinder: You will use one single-acting seal, as pressure is only ever applied from one direction.

- If your primary focus is design simplicity and cost-effectiveness: A single, double-acting seal is the most direct and efficient solution for a standard double-acting cylinder.

- If your primary focus is high-performance or heavy-duty operation: A back-to-back arrangement of two specialized single-acting seals often provides the most robust and durable sealing system.

Ultimately, understanding how pressure behaves in your system is the key to selecting the most reliable and effective seal.

Summary Table:

| Feature | Single-Acting Seal | Double-Acting Seal |

|---|---|---|

| Pressure Direction | One direction only | Both directions |

| Common Design | Asymmetrical (e.g., U-cup) | Symmetrical |

| Typical Configuration | Two seals back-to-back on a piston | Single seal on a piston |

| Piston Head Size | Longer (requires two grooves) | Shorter and more compact |

| Ideal For | High-performance, heavy-duty applications | Standard cylinders, design simplicity |

Need High-Performance PTFE Piston Seals?

Choosing the right seal is critical for your system's reliability and efficiency. At KINTEK, we specialize in manufacturing precision PTFE components, including custom piston seals for the semiconductor, medical, laboratory, and industrial sectors.

We offer:

- Custom Fabrication: From prototypes to high-volume orders.

- Material Expertise: PTFE for superior chemical resistance and low friction.

- Precision Production: Ensuring a perfect fit and long service life for your application.

Let our experts help you optimize your sealing solution. Contact KINTEK today for a consultation!

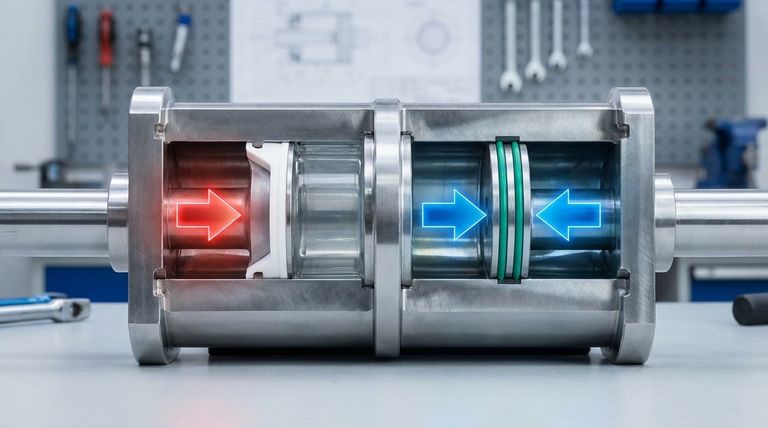

Visual Guide

Related Products

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE and Nitrile Diaphragm Pump Components for Demanding Applications

People Also Ask

- How do PTFE-lined valves prevent leakage and contamination? Ensure Purity and Protect Equipment

- What factors should be considered when choosing between PTFE lined and hard seal butterfly valves? Ensure Optimal Performance and Safety

- What material is the PTFE bottle made from? Discover the Benefits of 100% Virgin PTFE

- How does PTFE react to ammonia? Discover Its Superior Chemical Resistance

- How does PTFE behave in terms of chemical inertness? Unmatched Resistance for Demanding Applications