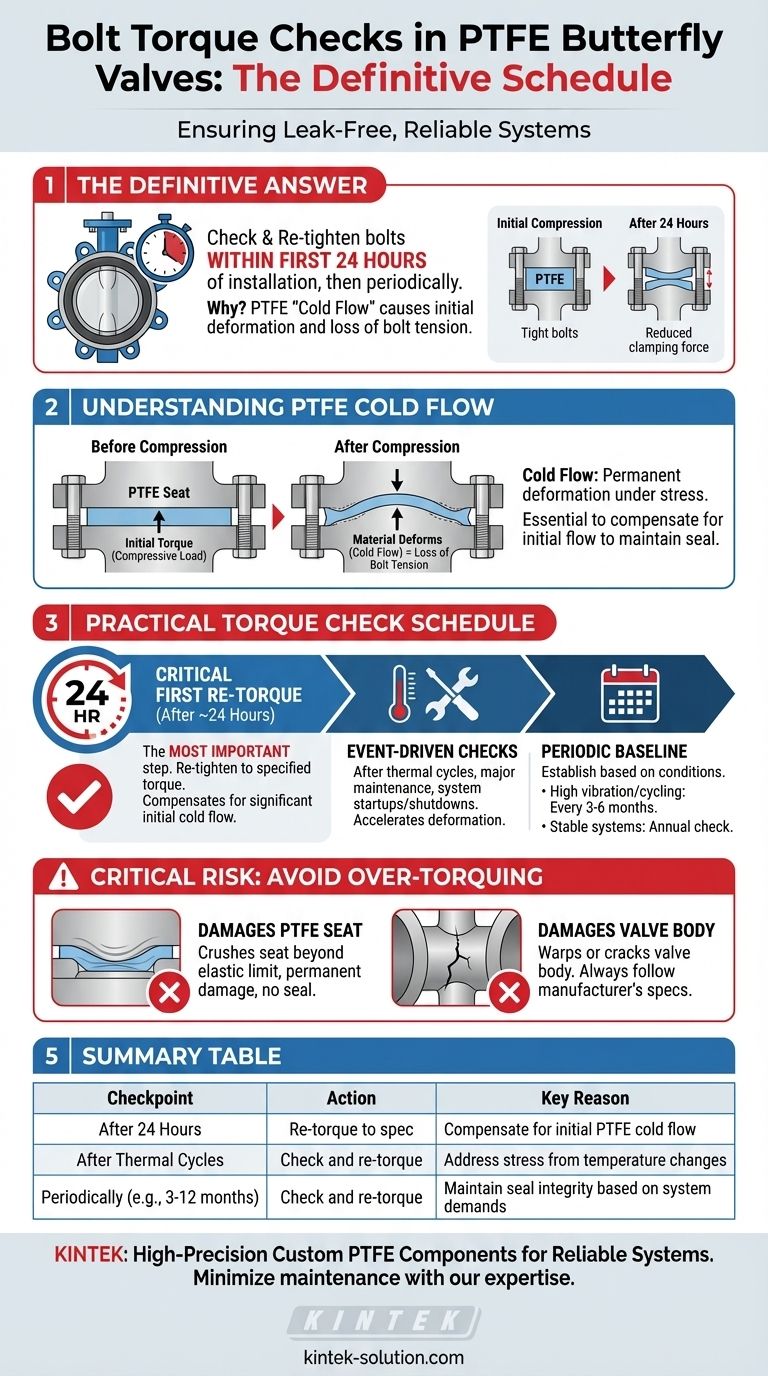

The definitive answer is that bolt torque on PTFE-lined or seated butterfly valves must be checked and re-tightened within the first 24 hours of initial installation and then periodically thereafter. Unlike a metal-to-metal connection, the soft PTFE material will deform under initial pressure, causing a loss of bolt tension that requires this critical follow-up check to prevent leaks.

The core issue is not the bolts loosening on their own, but a phenomenon called "cold flow" in the PTFE material. The PTFE seat or gasket slowly deforms under the initial compressive load, which reduces the clamping force and necessitates re-torquing to maintain a secure seal.

The Principle: Understanding PTFE Cold Flow

At the heart of this maintenance requirement is the physical nature of Polytetrafluoroethylene (PTFE), the material used for the valve seat or liner. Understanding this is key to preventing failures.

What is Cold Flow?

Cold flow (or "creep") is the tendency of a solid material to deform permanently under persistent mechanical stress. Softer materials like PTFE are highly susceptible to this.

When you first tighten the valve's flange bolts to the specified torque, you are compressing the PTFE seat to create a seal. However, this initial compression doesn't stop; the material continues to slowly "flow" or move away from the pressure point over time.

The Impact on Bolt Tension

This material deformation directly leads to a loss of bolt tension. The bolts themselves haven't loosened, but the material they are clamping down on has become thinner at the pressure points.

This creates a gap, however microscopic, which reduces the clamping force and can easily lead to a leak path, especially in systems with pressure or temperature fluctuations.

A Practical Schedule for Torque Checks

Because cold flow is most aggressive immediately after initial compression, your maintenance schedule should be event-driven, not just time-based.

The Critical First Re-Torque (After 24 Hours)

The most significant amount of cold flow occurs within the first day of installation.

Checking and re-tightening the bolts to their specified torque value approximately 24 hours after the initial installation is the single most important step you can take to ensure a long-term, leak-free seal.

After Thermal Cycles or Maintenance

Any event that significantly changes the stress on the valve requires a subsequent torque check.

This includes major maintenance, system startups and shutdowns, or any significant temperature and pressure cycling. These events can accelerate material deformation and require a torque check to confirm seal integrity.

Establishing a Periodic Baseline

After the initial 24-hour check, a periodic schedule should be established based on the system's operating conditions.

For systems with high vibration or frequent thermal cycling, checks might be warranted every 3-6 months. For more stable, less critical systems, an annual check during planned shutdowns may be sufficient.

The Critical Risk: Over-Torquing

While re-torquing is essential, it's crucial to avoid the common mistake of over-tightening the bolts. This can be just as damaging as a loose connection.

Damaging the PTFE Seat

Excessive torque can crush the PTFE seat beyond its elastic limit. This permanently damages the seat, destroying its ability to create a proper seal and often requiring a complete valve replacement.

Damaging the Valve Body

Over-torquing can also warp or crack the valve body itself, especially on non-metallic or lighter-duty valve bodies. Always adhere strictly to the manufacturer's specified torque values.

Making the Right Choice for Your System

Your strategy should be proactive and based on the specific demands of your application. Always follow the manufacturer's torque specifications and tightening patterns.

- For all new installations: Re-torque the flange bolts to the specified value 24 hours after the initial installation to compensate for initial PTFE cold flow.

- For systems with high vibration or thermal cycling: Implement a more frequent periodic check (e.g., quarterly or semi-annually) after the initial re-torque.

- For stable, non-critical systems: Establish an annual torque check as part of your standard preventative maintenance program.

Ultimately, treating a PTFE-seated valve as a dynamic seal that requires follow-up is the key to achieving long-term system reliability.

Summary Table:

| Checkpoint | Action | Key Reason |

|---|---|---|

| After 24 Hours | Re-torque to spec | Compensate for initial PTFE cold flow |

| After Thermal Cycles | Check and re-torque | Address stress from temperature changes |

| Periodically (e.g., 3-12 months) | Check and re-torque | Maintain seal integrity based on system demands |

Ensure your PTFE-sealed systems are leak-free and reliable.

Proper bolt torque is critical for the performance of PTFE components like seals, liners, and valve seats. KINTEK specializes in manufacturing high-precision, custom PTFE components for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your components are designed and fabricated to perform reliably in your specific application, minimizing maintenance issues.

Let our team help you select or custom-fabricate the right PTFE components for your needs, from prototypes to high-volume production.

Contact KINTEK today for a consultation and quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems