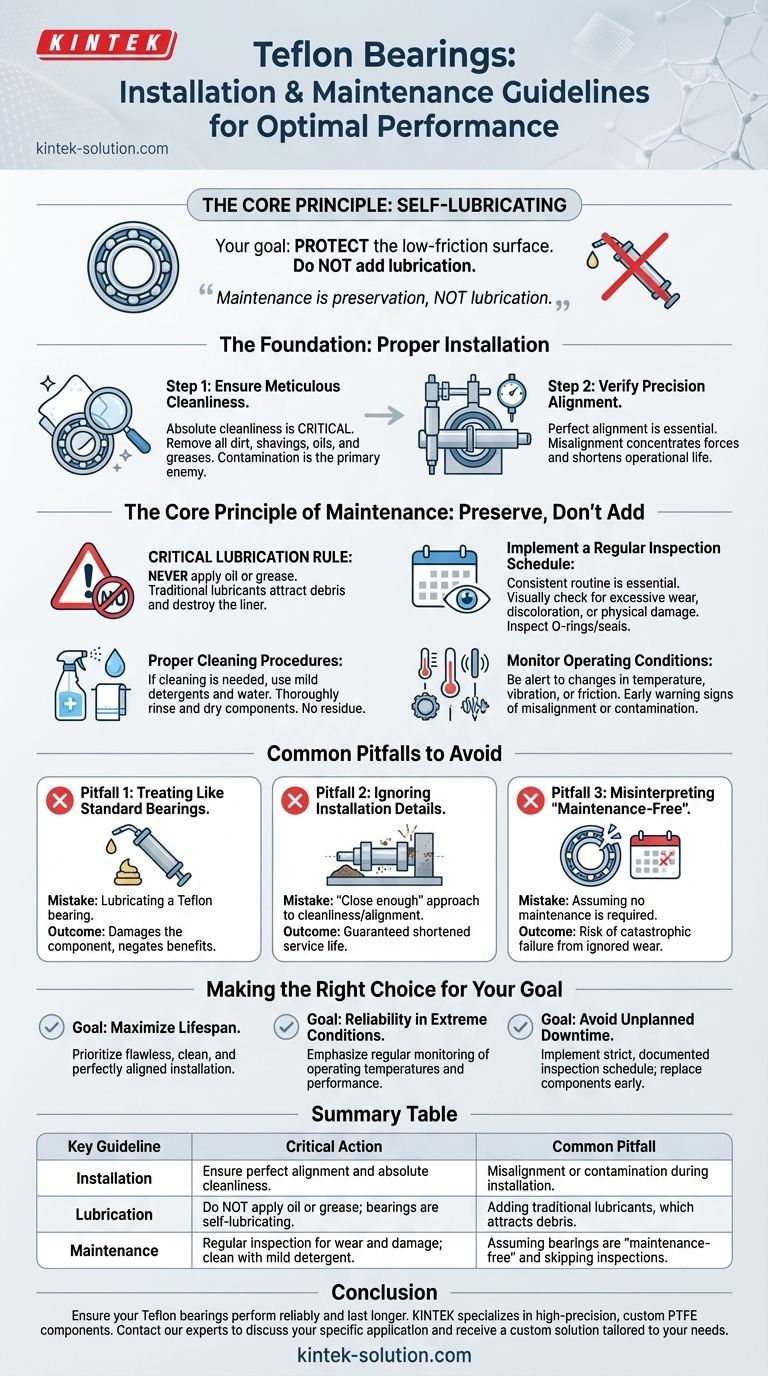

To ensure optimal performance, the installation of Teflon (PTFE) bearings centers on achieving perfect alignment and maintaining absolute cleanliness, free from any contaminants. Maintenance is a process of preservation, focused on regular inspection for wear and damage while strictly avoiding the traditional oils and greases used with other bearing types.

The core principle for Teflon bearings is that they are self-lubricating. Your goal during installation and maintenance is not to add lubrication, but to protect the bearing's inherent low-friction surface from mechanical damage and contamination.

The Foundation: Proper Installation

Successful installation is the most critical factor in the lifespan and performance of a Teflon bearing. Errors made at this stage are the primary cause of premature failure.

Step 1: Ensure Meticulous Cleanliness

The self-lubricating PTFE liner is the bearing's most important feature. It must be kept pristine.

Before and during installation, ensure the housing and shaft are completely free of dirt, metal shavings, and any residual oils or greases. Contamination is the primary enemy of a Teflon bearing surface.

Step 2: Verify Precision Alignment

Teflon bearings are designed to handle a specific load distribution. Misalignment concentrates forces on small areas of the bearing, leading to accelerated and uneven wear.

Use precision tools to ensure the shaft and housing bore are perfectly concentric and parallel. Even minor alignment issues can drastically reduce the bearing's operational life.

The Core Principle of Maintenance: Preserve, Don't Add

Because Teflon bearings lubricate themselves, maintenance practices are fundamentally different from those for traditional metallic bearings. The focus shifts from lubrication schedules to monitoring and inspection.

The Critical Lubrication Rule

Under no circumstances should you apply oil, grease, or other traditional lubricants to a PTFE-lined bearing.

These substances can attract dirt and debris, creating an abrasive paste that will destroy the low-friction liner. They interfere with the bearing's designed function and will cause it to fail.

Implement a Regular Inspection Schedule

"Self-lubricating" does not mean "zero-maintenance." A consistent inspection routine is essential for reliability.

Visually check the bearings for signs of excessive wear, discoloration, or physical damage. If the assembly includes O-rings or seals, inspect them for aging, deformation, or breakage and replace them as needed.

Proper Cleaning Procedures

If cleaning is necessary, use only mild detergents and water. Thoroughly rinse and dry the components before reassembly to ensure no residue remains.

Monitor Operating Conditions

Be alert to any changes in the equipment's environment or performance. Sudden increases in temperature, vibration, or friction are early indicators that the bearing may be compromised due to misalignment, contamination, or exceeding its load capacity.

Common Pitfalls to Avoid

Understanding why Teflon bearings fail is key to preventing it. The vast majority of issues stem from a misunderstanding of their unique properties.

Pitfall 1: Treating Them Like Standard Bearings

The most common mistake is lubricating a Teflon bearing. This single action negates the primary benefit of using it and actively damages the component.

Pitfall 2: Ignoring Installation Details

A "close enough" approach to alignment or cleanliness during installation will guarantee a shortened service life. Precision at the start prevents problems later.

Pitfall 3: Misinterpreting "Maintenance-Free"

While Teflon bearings do not require a lubrication schedule, they are not invincible. They must be inspected as part of any comprehensive preventative maintenance program to catch issues before they lead to catastrophic failure.

Making the Right Choice for Your Goal

Your maintenance strategy should directly support your operational objectives.

- If your primary focus is maximizing lifespan: Prioritize a flawless, clean, and perfectly aligned installation, as this has the greatest impact on longevity.

- If your primary focus is reliability in extreme conditions: Emphasize regular monitoring of operating temperatures and performance to detect signs of stress before failure occurs.

- If your primary focus is avoiding unplanned downtime: Implement a strict, documented inspection schedule for wear and replace components at the first sign of degradation.

Ultimately, protecting the integrity of the bearing's self-lubricating surface is the key to unlocking its long-term performance.

Summary Table:

| Key Guideline | Critical Action | Common Pitfall |

|---|---|---|

| Installation | Ensure perfect alignment and absolute cleanliness. | Misalignment or contamination during installation. |

| Lubrication | Do NOT apply oil or grease; bearings are self-lubricating. | Adding traditional lubricants, which attracts debris. |

| Maintenance | Regular inspection for wear and damage; clean with mild detergent. | Assuming bearings are "maintenance-free" and skipping inspections. |

Ensure your Teflon bearings perform reliably and last longer. KINTEK specializes in manufacturing high-precision, custom PTFE components, including seals, liners, and labware, for the semiconductor, medical, laboratory, and industrial sectors. From prototypes to high-volume orders, our expertise in material science and precision production ensures your components are built for optimal performance in demanding environments.

Contact our experts today to discuss your specific application and receive a custom solution tailored to your needs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- How does the low friction coefficient benefit PTFE lined butterfly valves? Reduce Torque and Extend Valve Life

- How often should a PTFE coating thrust washer be replaced? Proactive Maintenance for Peak Performance

- What support and warranty options are available for custom Teflon parts? Secure Your Investment with Full Manufacturer Backing

- What are the key characteristics of PTFE rotary seals? Superior Performance for Extreme Conditions

- What are the benefits of PTFE with aramid in gland packings? Achieve Superior Sealing Under Extreme Conditions

- What issue is associated with the leakage rate of PTFE ring gaskets? Overcoming Inherent Sealing Challenges

- How are rocker bearings integrated with PTFE sliding arrangements? Achieve Complex Multi-Directional Movement

- What are the process advantages of machining Teflon? High-Speed Production with Superior Thermal Stability