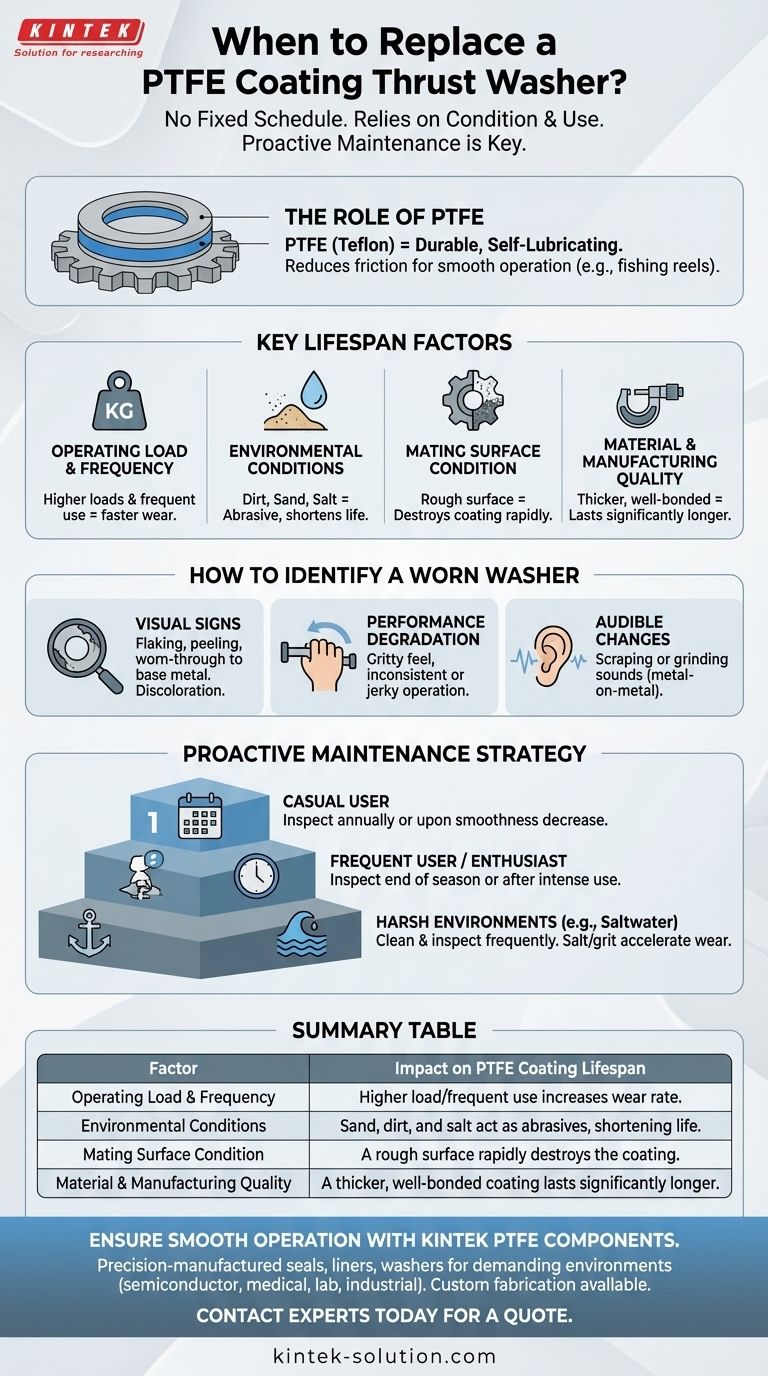

There is no fixed replacement schedule for a PTFE-coated thrust washer. Its lifespan is determined entirely by its operating conditions, the quality of the coating, and the intensity of its use. The correct approach is not to follow a calendar but to rely on regular inspection for signs of wear and performance degradation.

The core principle is proactive maintenance, not reactive replacement. Instead of asking "when" to replace the washer, the effective question is "what" to look for during routine inspections to determine if a replacement is necessary.

The Role of a PTFE Thrust Washer

What is PTFE?

PTFE (Polytetrafluoroethylene) is a synthetic polymer prized for its extremely low coefficient of friction. It's known commercially by brand names like Teflon.

How It Works

When applied as a coating to a metal thrust washer, PTFE creates a durable, self-lubricating surface. This coating is critical in applications like fishing reels, where it sits between components like the spool and the main gear to reduce friction, ensuring smooth and efficient operation.

Key Factors That Dictate Lifespan

The rate at which a PTFE coating wears down is not random; it is a direct result of the stresses placed upon it. Understanding these factors is key to predicting its service life.

Operating Load and Frequency

The amount of force (load) on the washer and how often it's used are the primary drivers of wear. Higher loads and more frequent use will abrade the PTFE coating more quickly.

Environmental Conditions

Exposure to contaminants drastically shortens a washer's life. Sand, dirt, and salt can embed in the coating or act as an abrasive, grinding the surface away much faster than normal operation would.

Mating Surface Condition

The washer's performance depends on the surface it runs against. A smooth, polished mating surface allows the PTFE to function correctly, while a rough or damaged surface will act like sandpaper, rapidly destroying the coating.

Material and Manufacturing Quality

Not all coatings are created equal. The thickness and application process of the PTFE layer are critical. A thicker, well-bonded coating from a reputable manufacturer will invariably outlast a thin, poorly applied one.

How to Identify a Worn Thrust Washer

Since replacement is based on condition, you must know what signs of failure to look for. These indicators can be visual, tactile, or audible.

Visual Signs of Wear

Look for areas where the coating is flaking, peeling, or has worn through to the base metal underneath. Discoloration can also be an early sign of heat-related stress or contamination.

Performance Degradation

This is the most common indicator. In a fishing reel, a worn washer may cause a "gritty" feeling when turning the handle or result in an inconsistent, jerky drag system. The operation is no longer smooth because the low-friction surface is gone.

Audible Changes

Listen for new noises. A faint scraping or grinding sound that wasn't present before often indicates that the PTFE coating has worn away and you now have metal-on-metal contact.

A Proactive Maintenance Strategy

Your maintenance schedule should be based on your usage profile. A one-size-fits-all approach is ineffective.

- If you are a casual user: Inspect the washer annually or anytime you notice a decrease in operational smoothness.

- If you are a frequent user or enthusiast: Plan to inspect key components, including the thrust washer, at the end of each season or after every few intense uses.

- If you operate in harsh environments (e.g., saltwater): You must clean and inspect your equipment far more frequently, as salt and grit are powerful abrasives that accelerate wear.

Ultimately, understanding how your equipment works is the best way to maintain it for peak performance and longevity.

Summary Table:

| Factor | Impact on PTFE Coating Lifespan |

|---|---|

| Operating Load & Frequency | Higher load/frequent use increases wear rate. |

| Environmental Conditions | Sand, dirt, and salt act as abrasives, shortening life. |

| Mating Surface Condition | A rough surface rapidly destroys the coating. |

| Material & Manufacturing Quality | A thicker, well-bonded coating lasts significantly longer. |

Ensure your equipment runs smoothly with high-performance PTFE components from KINTEK.

Is inconsistent performance or a gritty feel affecting your operation? Our precision-manufactured PTFE seals, liners, washers, and labware are engineered for durability and low friction in the most demanding environments, including semiconductor, medical, laboratory, and industrial applications.

We offer custom fabrication from prototypes to high-volume orders, ensuring a perfect fit and superior performance for your specific needs.

Contact our experts today to discuss your requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications