To be direct, reputable manufacturers of custom Teflon parts provide a comprehensive support structure that includes dedicated customer service, detailed installation guidance, and full warranty coverage. This ecosystem is designed not just as an after-sale service, but as a critical component to ensure the specialized part performs exactly as intended within its demanding application.

The support and warranty offered for a custom Teflon part are a direct reflection of the manufacturer's confidence in their materials and machining precision. For the end-user, this translates into a partnership aimed at ensuring the component's performance, reliability, and long service life from day one.

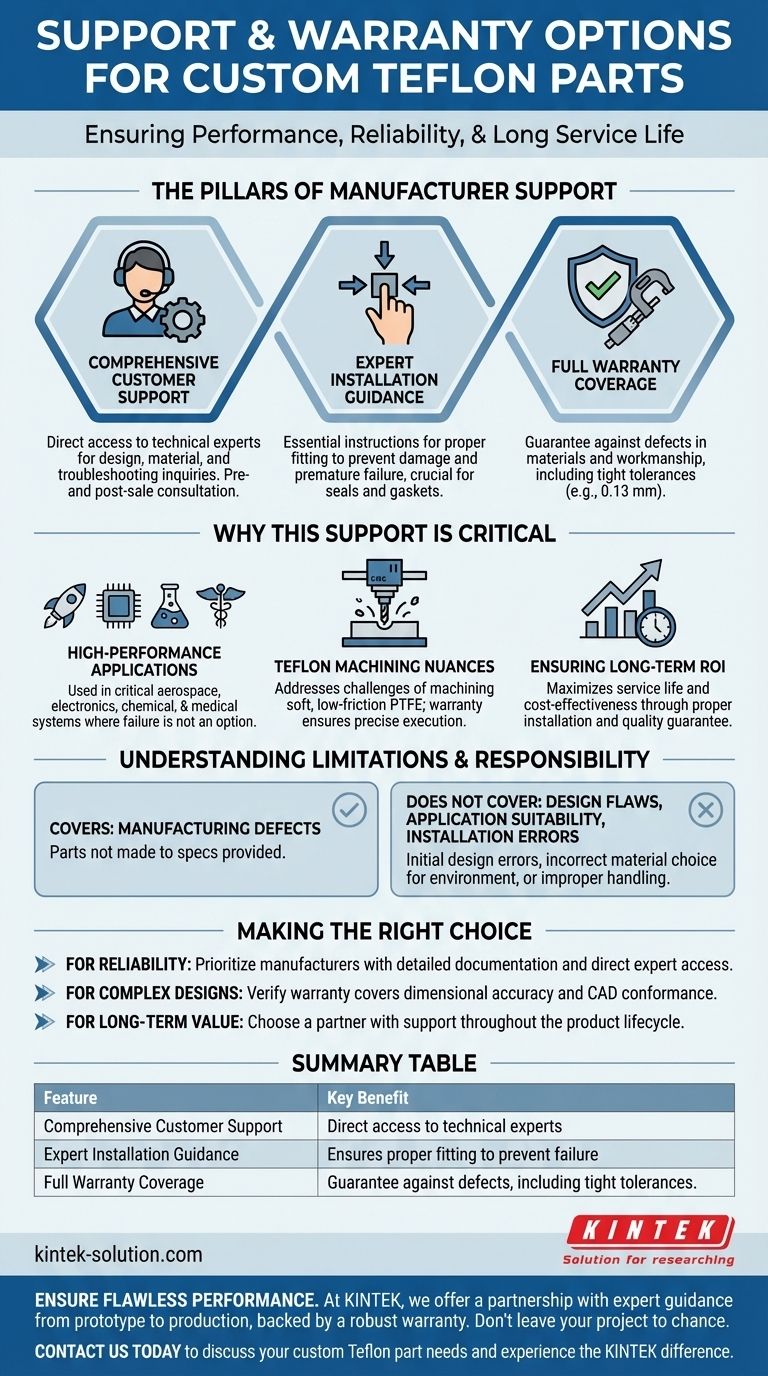

The Pillars of Manufacturer Support

When you procure a custom-machined Teflon component, you are investing in more than just the physical item. The associated services are vital for ensuring the part delivers its expected value in high-stakes environments.

Comprehensive Customer Support

This is your first point of contact for any technical inquiries. It covers questions about material specifications, design feasibility before production, and troubleshooting performance issues after installation. This direct line to expertise is crucial for specialized components.

Expert Installation Guidance

A precisely machined part can fail if installed incorrectly. Manufacturers provide guidance to ensure the component is fitted properly, preventing damage and premature failure. This is especially important for parts like seals and gaskets where proper seating is critical for performance.

Full Warranty Coverage

The warranty is your assurance against defects in materials and workmanship. It guarantees that the part you receive meets the agreed-upon specifications, including the tight tolerances often required, which can be as precise as 0.13 mm.

Why This Level of Support is Critical

The unique properties of Teflon (PTFE) and the demanding industries it serves make a robust support system non-negotiable. It addresses the inherent challenges and protects your investment.

The Demands of High-Performance Applications

Custom Teflon parts are not commodity items. They are used in critical systems within the aerospace, electronics, chemical processing, and medical industries. In these fields, component failure can have severe consequences, making manufacturer backing essential.

The Nuances of Teflon Machining

Teflon's characteristics—such as its relative softness and low friction—make it challenging to machine with high precision. CNC machining with controlled parameters is necessary. The manufacturer's warranty is a guarantee that this complex process was executed correctly.

Ensuring Long-Term ROI

The benefits of Teflon include long service life and cost-effectiveness. Proper installation and a guarantee of quality are what allow you to realize this return on investment. Without support, you risk premature replacement and operational downtime.

Understanding the Limitations and Shared Responsibility

An objective view requires understanding what a support and warranty structure typically does not cover. This clarity is key to a successful partnership with your manufacturer.

Design vs. Manufacturing Defects

A warranty covers defects in manufacturing—the part was not made to the specifications you provided. It does not cover a part that fails because the initial design itself was flawed for the intended application.

Application Suitability

The warranty guarantees the part is made of Teflon and meets dimensional specs. It does not guarantee that Teflon was the correct material choice for your specific chemical, thermal, or mechanical environment. This is why pre-sale technical consultation is so valuable.

Installation Execution

While a manufacturer provides guidance, they are not responsible for errors made during the physical installation process. A warranty may be voided if the part was damaged due to improper handling or fitting by the end-user.

Making the Right Choice for Your Goal

To ensure you are fully protected, align your procurement strategy with the specific demands of your project.

- If your primary focus is reliability in a critical system: Prioritize manufacturers who offer detailed installation documentation and direct access to technical experts for pre- and post-sale consultation.

- If your primary focus is achieving a complex design: Verify the manufacturer's warranty explicitly covers dimensional accuracy and conformance to your technical drawings and CAD files.

- If your primary focus is long-term value: Choose a partner whose support extends throughout the product lifecycle, as this ensures you maximize the part's service life and avoid unnecessary replacement costs.

Ultimately, viewing support and warranty as integral features of the component itself is the best way to ensure success from design to long-term operation.

Summary Table:

| Support & Warranty Feature | Key Benefit |

|---|---|

| Comprehensive Customer Support | Direct access to technical experts for pre- and post-sale consultation |

| Expert Installation Guidance | Ensures proper fitting to prevent damage and premature failure |

| Full Warranty Coverage | Guarantee against defects in materials and workmanship, including tight tolerances (e.g., 0.13 mm) |

Ensure your custom PTFE components perform flawlessly in demanding applications. At KINTEK, we provide more than just parts—we offer a partnership. Our dedicated support includes expert guidance from prototype to high-volume production, backed by a robust warranty that covers precision manufacturing for semiconductor, medical, laboratory, and industrial applications.

Don't leave your project to chance. Contact us today to discuss your custom Teflon part needs and experience the KINTEK difference.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support