In short, combining PTFE with aramid fibers in gland packings creates a superior hybrid material that marries the chemical inertness and low friction of PTFE with the exceptional strength and abrasion resistance of aramid. This results in a packing that can withstand high pressures, high speeds, and abrasive media that would cause simpler materials to fail.

The core problem with many sealing applications is the battle between chemical resistance and mechanical strength. PTFE-aramid packing solves this by using aramid fibers as a structural reinforcement, preventing the chemically resistant but mechanically soft PTFE from failing under stress.

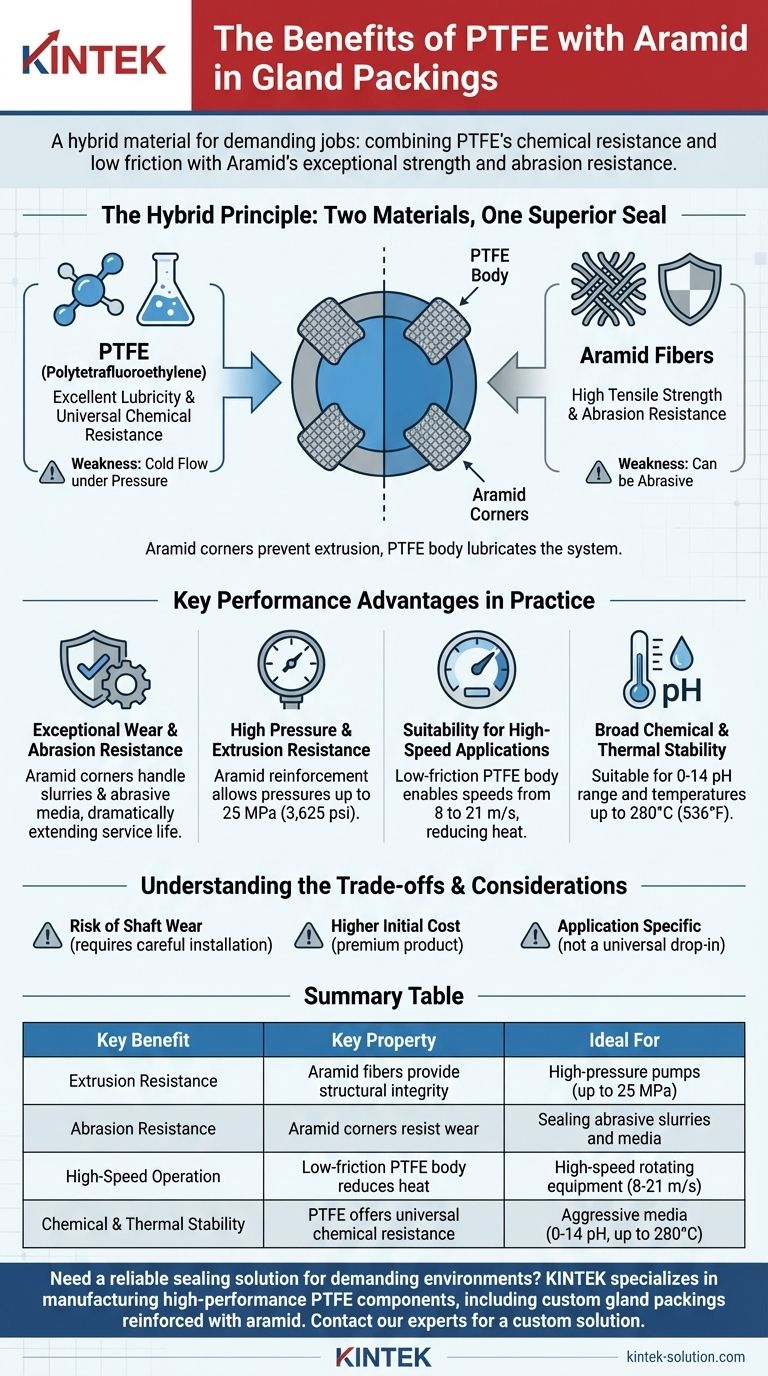

The Principle: A Hybrid Material for Demanding Jobs

To understand the benefits of this combination, we must first appreciate the distinct properties of each component and how they complement one another.

The Role of PTFE (Polytetrafluoroethylene)

PTFE is renowned for its extremely low coefficient of friction and its chemical inertness. Think of it as the industrial equivalent of a high-performance, non-stick coating.

Its primary contributions are excellent lubricity, which reduces friction and heat on the rotating shaft, and near-universal chemical resistance, allowing it to seal aggressive media across the entire 0-14 pH range.

However, PTFE's main weakness is its tendency to cold flow or "extrude" under high pressure, meaning it can be squeezed out of the gland, leading to seal failure.

The Role of Aramid Fibers

Aramid fibers, part of the same family as materials used in ballistic-rated body armor, are known for their incredibly high tensile strength and abrasion resistance.

When woven into a packing, aramid provides a tough, durable structure that resists mechanical wear and tear. Its primary function is to provide structural integrity and strength.

On its own, however, an all-aramid packing can be abrasive and potentially cause wear to the equipment shaft or sleeve over time.

How the Combination Creates a Superior Seal

The most effective designs weave aramid fibers into the corners of a PTFE packing. This strategic placement creates a composite material with the best qualities of both.

The strong aramid corners act as anti-extrusion barriers. They contain the softer PTFE body, preventing it from being squeezed out under high pressure and providing a robust wiping action against abrasive particles.

The PTFE body lubricates the entire system, protecting the shaft from the toughness of the aramid while providing the primary chemical seal.

Key Performance Advantages in Practice

This hybrid construction translates directly into measurable performance benefits in challenging industrial environments.

Exceptional Wear and Abrasion Resistance

The aramid corners are designed to handle abrasive slurries and media with high solids content. They provide the toughness needed to resist being worn away, dramatically extending the packing's service life.

High Pressure and Extrusion Resistance

The reinforcement provided by the aramid fibers gives the packing the backbone to withstand high operational pressures, often in the range of 15 to 25 MPa (2,175 to 3,625 psi), without extruding from the stuffing box.

Suitability for High-Speed Applications

The low-friction PTFE body allows for higher shaft surface speeds, typically from 8 to 21 m/s. It minimizes frictional heat generation, which is a common cause of packing failure in high-speed pumps.

Broad Chemical and Thermal Stability

The packing inherits the exceptional stability of PTFE, making it suitable for service in temperatures up to 280°C (536°F) and across the full pH spectrum from 0 to 14.

Understanding the Trade-offs and Considerations

While highly effective, this packing is a specialized solution. Its strengths come with considerations that must be weighed for proper application.

The Risk of Shaft Wear

Aramid is an inherently tough material. If the packing is over-tightened during installation or if the PTFE's lubrication is compromised, the aramid fibers can score or groove the shaft sleeve. This is the most critical trade-off and requires careful installation and monitoring.

Higher Initial Cost

PTFE-aramid packing is a premium product. Its cost is higher than standard graphite or pure PTFE alternatives. The investment must be justified by significantly longer service life or its unique ability to perform in an application where other packings fail quickly.

Application Specificity

This packing is not a universal "drop-in" for every pump. It is engineered specifically for demanding services involving high pressure, high speed, or abrasive media. Using it in a clean, low-pressure water service may be unnecessary and introduces a needless risk of shaft wear.

Making the Right Choice for Your Application

Selecting the correct packing requires matching the material's capabilities to the operational demands.

- If your primary focus is sealing abrasive slurries: A PTFE-aramid packing is an excellent choice, as the aramid corners provide superior abrasion resistance.

- If your primary focus is preventing packing extrusion in high-pressure pumps: The aramid reinforcement provides the necessary structural strength to ensure a stable, long-lasting seal.

- If your primary focus is reducing failures in high-speed rotating equipment: The combination of low-friction PTFE and high-strength aramid allows for higher speeds with greater stability.

- If your primary focus is general chemical service without high pressure or abrasives: A high-quality pure PTFE or graphite-based packing may be a more cost-effective and lower-risk solution.

By understanding this balance of properties, you can specify the right packing to enhance equipment reliability and reduce long-term operational costs.

Summary Table:

| Key Benefit | Key Property | Ideal For |

|---|---|---|

| Extrusion Resistance | Aramid fibers provide structural integrity | High-pressure pumps (up to 25 MPa) |

| Abrasion Resistance | Aramid corners resist wear | Sealing abrasive slurries and media |

| High-Speed Operation | Low-friction PTFE body reduces heat | High-speed rotating equipment (8-21 m/s) |

| Chemical & Thermal Stability | PTFE offers universal chemical resistance | Aggressive media (0-14 pH, up to 280°C) |

Need a reliable sealing solution for demanding environments? KINTEK specializes in manufacturing high-performance PTFE components, including custom gland packings reinforced with aramid for the semiconductor, medical, laboratory, and industrial sectors. Our precision production ensures your equipment operates reliably under extreme pressure, speed, and abrasive conditions. Contact our experts today to discuss your specific application and receive a custom solution—from prototype to high-volume order.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- Is PTFE approved for food contact applications? Ensuring Food Safety with Compliant PTFE

- In which industries are spring-energized PTFE seals commonly used? Critical Applications for Extreme Conditions

- What are the advantages of spring-loaded lift check valves? Achieve Reliable, Non-Slam Backflow Prevention

- What are the key benefits of using PTFE in CNC machining? Achieve Unmatched Performance in Harsh Environments

- How does the machining process for Teflon differ from machining metals? A Guide to Precision and Finesse

- What are the advantages and disadvantages of composite PTFE diaphragms? Balancing Chemical Resistance and Flexibility

- What are the main technical features of PTFE rotary shaft seals? Unlock Extreme Performance & Reliability

- Why is PTFE considered an ideal material for demanding hydraulic and pneumatic applications? Ensure Superior Sealing Performance and Reliability