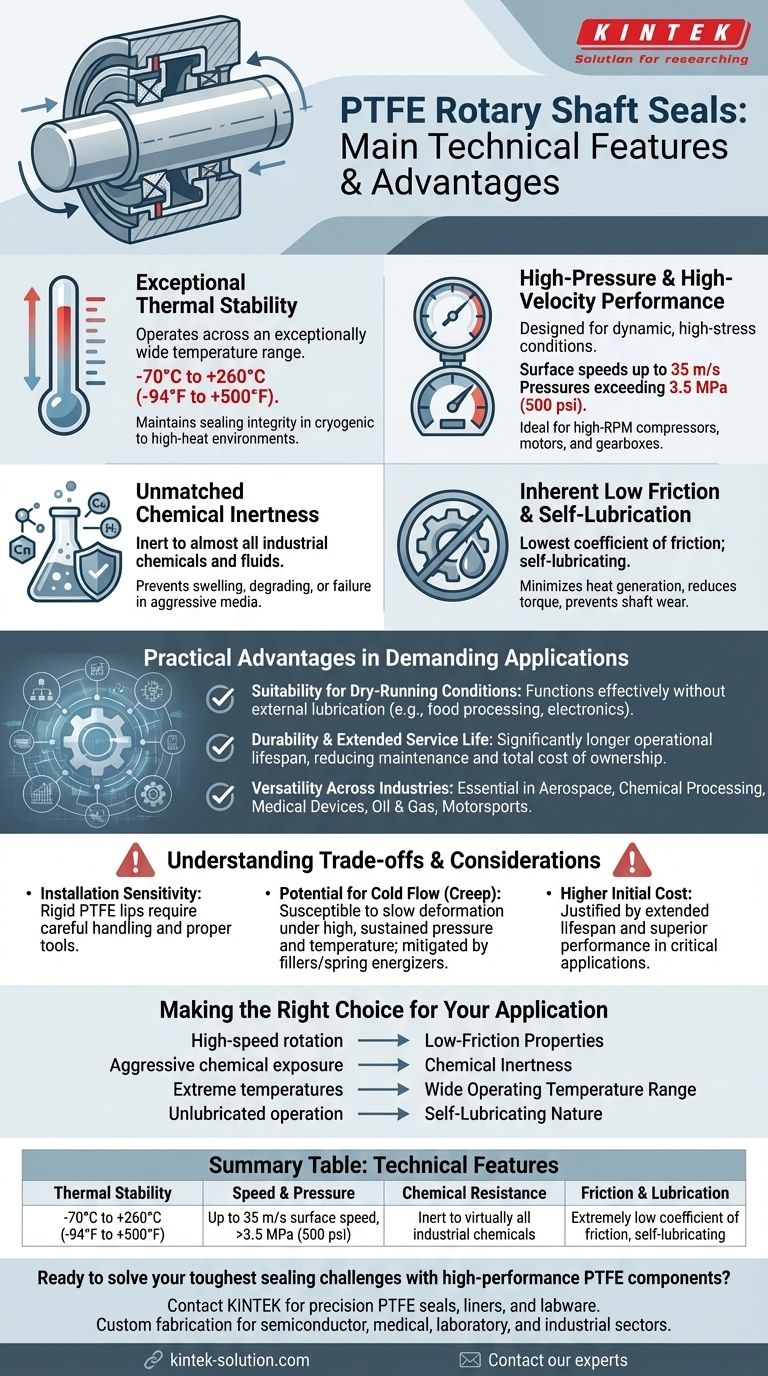

The defining technical features of PTFE rotary shaft seals are their capacity to perform reliably under extreme operational demands. They are engineered for high speeds, wide temperature ranges, significant pressures, and near-universal chemical resistance, far exceeding the capabilities of traditional elastomeric seals.

The core value of a PTFE seal is not just its excellence in a single category, but its unique ability to handle a combination of extreme conditions simultaneously—such as high speed in a corrosive chemical environment—where conventional seals would quickly fail.

Core Technical Capabilities of PTFE Seals

To understand why PTFE seals are specified for mission-critical applications, we must examine their fundamental material properties. These capabilities work in concert to deliver robust performance.

Exceptional Thermal Stability

PTFE seals operate effectively across an exceptionally wide temperature range, typically from -70°C to +260°C (-94°F to +500°F). This allows them to maintain sealing integrity in environments from cryogenic applications to high-heat industrial machinery without becoming brittle or degrading.

High-Pressure and High-Velocity Performance

These seals are designed for dynamic, high-stress conditions. They can handle surface speeds up to 35 m/s and pressures exceeding 3.5 MPa (500 psi). This makes them ideal for high-RPM equipment like compressors, motors, and gearboxes.

Unmatched Chemical Inertness

PTFE is inert to almost all industrial chemicals and fluids. This exceptional chemical resistance prevents the seal from swelling, degrading, or failing when exposed to aggressive media, a common failure point for standard rubber seals.

Inherent Low Friction and Self-Lubrication

PTFE has one of the lowest coefficients of friction of any solid material. This self-lubricating property minimizes heat generation at the contact point, reduces torque requirements, and prevents shaft wear.

The Practical Advantages in Demanding Applications

These technical features translate directly into tangible operational benefits, extending equipment life and reducing downtime.

Suitability for Dry-Running Conditions

The self-lubricating nature of PTFE allows these seals to function effectively without external lubrication. This is a critical advantage in applications like food processing or electronics manufacturing, where lubricant contamination is unacceptable.

Durability and Extended Service Life

The combination of low friction, chemical inertness, and wear resistance results in a significantly longer operational lifespan. This durability reduces the frequency of maintenance cycles and lowers the total cost of ownership.

Versatility Across Industries

The unique properties of PTFE seals make them essential components in a wide range of demanding fields. You will find them in aerospace, chemical processing, medical devices, oil and gas, and high-performance motorsports, where reliability is paramount.

Understanding the Trade-offs and Considerations

While powerful, PTFE seals are not a universal solution. An objective assessment requires understanding their specific requirements and limitations.

Installation Sensitivity

Unlike flexible elastomeric seals, PTFE lips are relatively rigid. They are less forgiving of shaft imperfections and require careful handling and proper installation tools to avoid nicking or damaging the seal lip, which would compromise its performance.

Potential for Cold Flow (Creep)

Under high, sustained pressure and temperature, PTFE can be susceptible to "cold flow" or creep. This is a slow deformation of the material that can, over a long period, reduce the sealing force on the shaft. Seal design often incorporates fillers and spring energizers to mitigate this effect.

Higher Initial Cost

High-performance materials and manufacturing processes mean that PTFE seals typically have a higher upfront cost compared to standard nitrile or viton seals. The investment is justified by their extended lifespan and superior performance in applications where other materials would fail.

Making the Right Choice for Your Application

Selecting the correct seal depends entirely on the operational demands of your equipment.

- If your primary focus is high-speed rotation: PTFE's low-friction properties minimize heat buildup and wear, making it the superior choice.

- If your primary focus is aggressive chemical exposure: PTFE's chemical inertness ensures the seal will not degrade, providing long-term reliability.

- If your primary focus is extreme temperatures (hot or cold): The wide operating temperature range of PTFE ensures it maintains its integrity and sealing force.

- If your primary focus is unlubricated (dry-running) operation: The self-lubricating nature of PTFE is essential for preventing catastrophic failure.

Ultimately, selecting a PTFE rotary shaft seal is an investment in operational reliability for applications where failure is not an option.

Summary Table:

| Technical Feature | Key Performance Metric |

|---|---|

| Thermal Stability | -70°C to +260°C (-94°F to +500°F) |

| Speed & Pressure | Up to 35 m/s surface speed, >3.5 MPa (500 psi) |

| Chemical Resistance | Inert to virtually all industrial chemicals |

| Friction & Lubrication | Extremely low coefficient of friction, self-lubricating |

Ready to solve your toughest sealing challenges with high-performance PTFE components?

At KINTEK, we specialize in manufacturing precision PTFE seals, liners, and labware for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures you get a reliable sealing solution tailored to your specific operational demands, whether it's for high-speed, extreme temperatures, or aggressive chemical environments.

Contact our experts today to discuss your application and discover how KINTEK's PTFE components can enhance your equipment's reliability and lifespan.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- How does a PTFE lined ball valve work? A Guide to Corrosion-Free Flow Control

- What role does PTFE play in football field maintenance? Boost Equipment Performance & Field Quality

- What is the purpose of dimples on the PTFE surface of these bearings? Enhancing Lubrication and Longevity

- How do PTFE seals enhance sealing performance in ball valves? Achieve Superior, Leak-Proof Sealing

- How is glass-filled PTFE used in construction? Enhance Structural Integrity & Durability

- In which components of a mechanical seal is PTFE commonly used? Solve Sealing Challenges with Chemical Resistance

- What are the key characteristics of PTFE that make it suitable for lip seals? Engineered for Extreme Performance

- How does the low coefficient of friction in PTFE bushes benefit industrial applications? Reduce Wear & Maintenance