At its core, PTFE enhances ball valve sealing performance through a unique combination of extreme chemical inertness, an exceptionally low coefficient of friction, and material stability. This synergy creates a seal that is not only tight and leak-proof but also remarkably durable and resistant to wear, even in the most demanding industrial environments.

The true advantage of PTFE is not a single feature, but how its distinct properties—chemical resistance, self-lubrication, and a non-stick surface—work together to deliver a reliable, long-lasting, and low-maintenance seal that outperforms many alternatives.

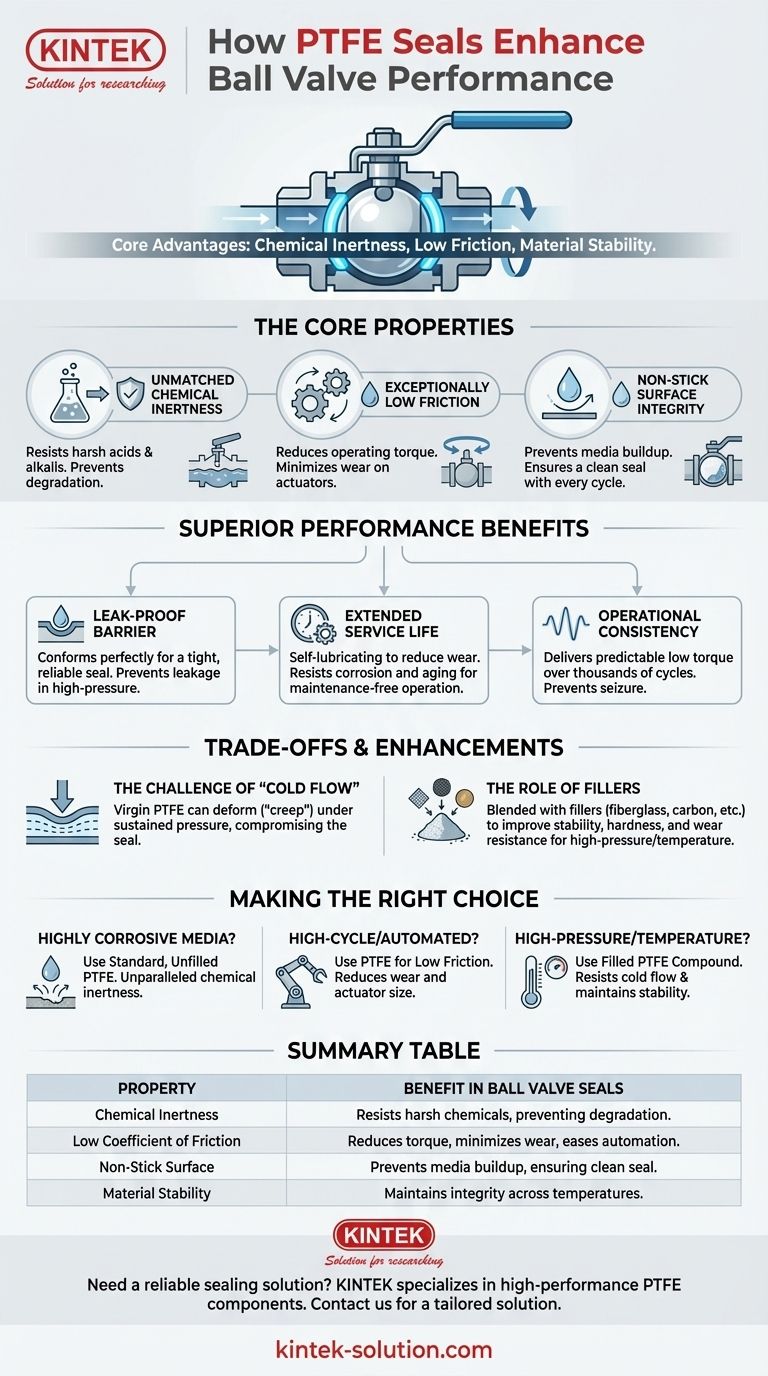

The Core Properties of PTFE Seals

To understand why PTFE is a superior sealing material, we must first examine its fundamental characteristics. Each property addresses a specific operational challenge faced by ball valves.

Unmatched Chemical Inertness

PTFE is virtually immune to chemical attack. It maintains stable sealing performance when handling harsh media like strong acids, strong alkalis, and other corrosive fluids, effectively preventing leakage where other materials would quickly degrade.

Exceptionally Low Friction

PTFE has one of the lowest coefficients of friction of any solid material. This self-lubricating property is critical for reducing the torque required to open and close the valve, which minimizes stress on actuators and manual controls.

Non-Stick Surface Integrity

The material's non-stick nature prevents process media from adhering to the sealing surface. This ensures a clean seal with every cycle and prevents the buildup of deposits that could otherwise compromise the valve's integrity.

How These Properties Translate to Superior Performance

These inherent characteristics directly result in tangible operational benefits, making PTFE the material of choice for critical sealing applications.

Creating a Leak-Proof Barrier

The inherent properties of PTFE allow it to conform perfectly between the ball and the valve body, forming a tight, reliable seal. This prevents medium leakage even in high-pressure or corrosive service.

Extending Valve Service Life

Because PTFE is self-lubricating, it dramatically reduces wear on the sealing surfaces during operation. Combined with its resistance to corrosion and aging, this significantly extends the maintenance-free service life of the entire valve assembly.

Ensuring Operational Consistency

Valves with PTFE seals deliver consistent performance over thousands of cycles. The low friction and non-stick surface ensure that the torque required for operation remains low and predictable over time, preventing seizure and ensuring reliability.

Understanding the Trade-offs and Enhancements

While standard PTFE is highly effective, it is not without limitations. Understanding these trade-offs is key to specifying the correct material for a given application.

The Challenge of "Cold Flow"

Unfilled, or "virgin," PTFE has a tendency to deform or "creep" over time when subjected to sustained pressure, a phenomenon known as cold flow. In high-pressure applications, this can eventually compromise the seal's integrity.

The Role of Fillers and Additives

To counteract cold flow and improve mechanical properties, PTFE is often blended with fillers. Materials like fiberglass, carbon, bronze, or nickel are added to improve dimensional stability, hardness, and resistance to wear and creep. This makes filled PTFE suitable for more demanding high-pressure and high-temperature services.

Making the Right Choice for Your Application

Selecting the correct PTFE seal composition is critical for maximizing performance and valve longevity.

- If your primary focus is handling highly corrosive media: Standard, unfilled PTFE is often the best choice due to its unparalleled chemical inertness.

- If your primary focus is high-cycle or automated applications: The low friction of a PTFE seal is essential for reducing wear and minimizing the size and cost of the actuator.

- If your primary focus is high-pressure or high-temperature service: You must specify a filled PTFE compound to resist cold flow and maintain dimensional stability under stress.

By understanding these principles, you can confidently specify the precise PTFE sealing solution that ensures reliability and longevity in your system.

Summary Table:

| Property | Benefit in Ball Valve Seals |

|---|---|

| Chemical Inertness | Resists harsh acids, alkalis, and solvents, preventing degradation. |

| Low Coefficient of Friction | Reduces operating torque, minimizes wear, and eases automation. |

| Non-Stick Surface | Prevents media buildup, ensuring a clean seal with every cycle. |

| Material Stability | Maintains integrity across a wide temperature range for consistent performance. |

Need a reliable sealing solution for your critical application?

KINTEK specializes in manufacturing high-performance PTFE components, including seals, liners, and custom labware. Whether you're in the semiconductor, medical, laboratory, or industrial sector, our expertise in precision production and custom fabrication—from prototypes to high-volume orders—ensures you get a seal that delivers leak-proof performance, extended service life, and reduced maintenance.

Contact KINTEK today to discuss your specific requirements and let our experts provide a tailored PTFE sealing solution for your ball valves.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are some examples of PTFE's use in civil engineering? Manage Structural Movement and Load

- What is the chemical resistance of Teflon encapsulated O-rings? The Ultimate Guide to Inert Sealing

- What advantages do PTFE spring-energized seals offer in harsh environments? Unlock Unmatched Reliability

- What are the advantages of PTFE rotary shaft lip seals? Superior Performance in Extreme Conditions

- What are the key properties of PTFE that make it suitable for seals? Unlock Reliability in Extreme Conditions

- Why is PTFE used in electrical insulation? Superior Performance in Extreme Conditions

- What are the chemical resistance properties of PTFE? Unmatched Inertness for Demanding Applications

- What practical experience exists with PEEK-seated ball valves in similar conditions? Proven Performance at 400°F