In short, the dimples on a PTFE bearing surface act as reservoirs for lubricant. Their purpose is to hold grease or oil directly at the point of contact, ensuring a consistent, low-friction film is maintained between the sliding surfaces. This design significantly reduces wear and extends the operational life of the bearing.

The central challenge with sliding bearings is preventing the lubricant from being squeezed out under pressure. The dimpled surface solves this by creating a distributed network of tiny reservoirs, ensuring lubricant is always available to maintain separation between moving parts.

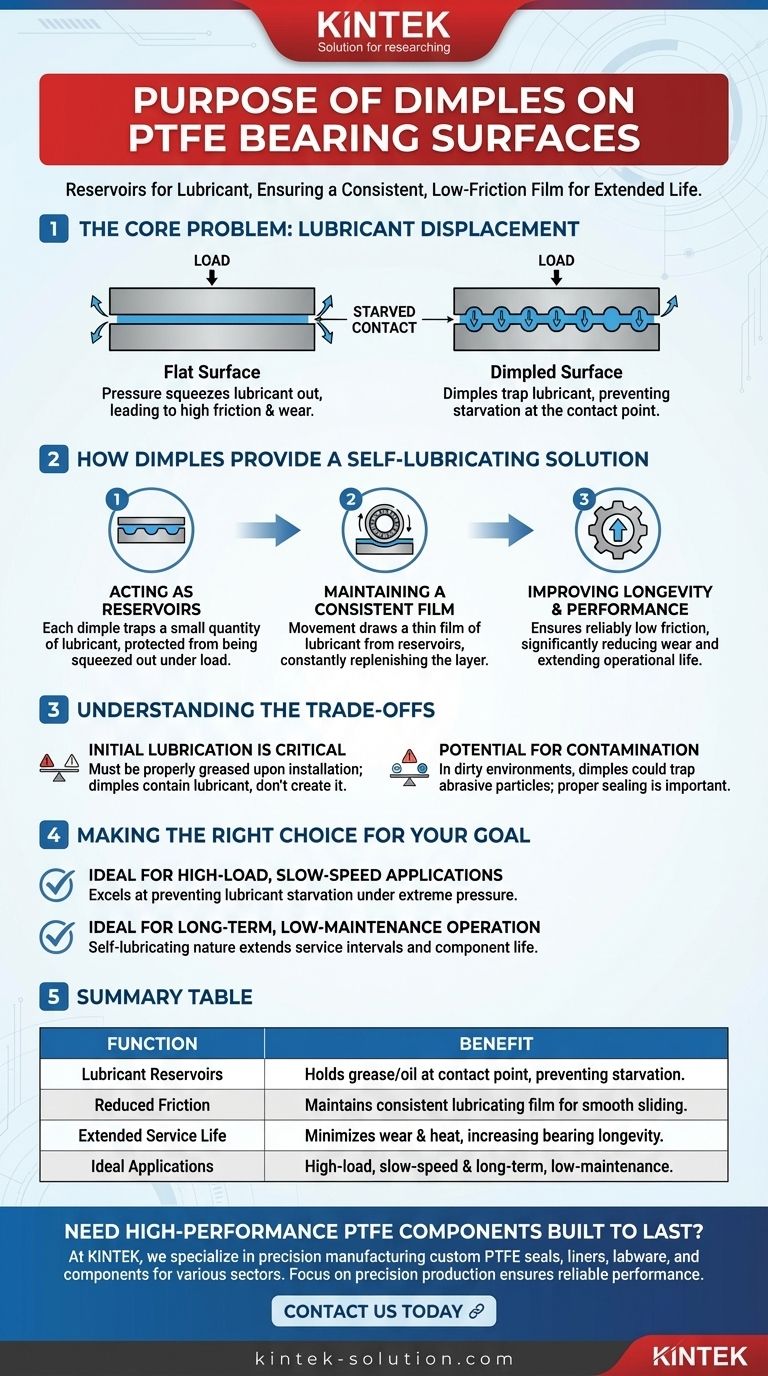

The Core Problem: Lubricant Displacement

To understand the value of dimples, we must first examine the fundamental issue they are designed to solve. Any bearing's primary function is to reduce friction between moving components.

The Challenge with Flat Surfaces

On a perfectly flat bearing surface, applying a load has a simple and detrimental effect. The pressure between the two contact points will squeeze the lubricant out to the sides.

This process, known as lubricant displacement, leaves the contact points "starved" of lubrication precisely where it is needed most.

The Result: Increased Friction and Wear

Once the lubricant is displaced, you transition from a low-friction, fluid-film condition to a high-friction, boundary condition. This can lead to direct PTFE-to-metal contact.

This direct contact dramatically increases friction, generates heat, and accelerates the wear and degradation of the PTFE liner, shortening the bearing's life.

How Dimples Provide a Self-Lubricating Solution

The dimpled pattern is an elegant engineering solution that transforms the bearing surface into an active lubrication system.

Acting as Lubricant Reservoirs

Each dimple functions as a micro-reservoir, trapping a small quantity of lubricant. Even when the bearing is under significant load, the lubricant within these pockets is protected from being completely squeezed out.

Maintaining a Consistent Film

As the bearing moves, the sliding surfaces draw a thin film of lubricant from these reservoirs. This process constantly replenishes the lubricating layer, easing sliding movements and ensuring the components remain separated.

Improving Longevity and Performance

By maintaining a consistent lubricant film, the dimpled design ensures reliably low friction. This directly translates to improved performance and longevity, as the primary causes of wear and premature failure are effectively mitigated.

Understanding the Trade-offs

While highly effective, this design is not without its considerations. Understanding its operational principles is key to using it correctly.

Initial Lubrication is Critical

The dimples are designed to contain lubricant, not to function without it. A dimpled bearing must be properly greased upon installation. The dimples' function is to keep that initial lubricant where it belongs for the long term.

Potential for Contamination

In extremely dirty or dusty environments, the dimples could potentially trap abrasive contaminants. While this is a minor concern in most applications, it highlights the importance of proper sealing for bearings operating in harsh conditions.

Making the Right Choice for Your Goal

The dimpled PTFE surface is engineered for specific operational demands.

- If your primary focus is high-load, slow-speed applications: This design is ideal, as it excels at preventing lubricant starvation under the exact conditions that would squeeze it out of a flat bearing.

- If your primary focus is long-term, low-maintenance operation: The self-lubricating nature of the dimpled surface provides a "set it and forget it" reliability, extending service intervals and component life.

Ultimately, the dimpled surface turns a simple component into a more robust and reliable self-sustaining system.

Summary Table:

| Function | Benefit |

|---|---|

| Lubricant Reservoirs | Holds grease/oil at the contact point, preventing starvation under load. |

| Reduced Friction | Maintains a consistent lubricating film for smooth, low-friction sliding. |

| Extended Service Life | Minimizes wear and heat generation, significantly increasing bearing longevity. |

| Ideal Applications | High-load, slow-speed, and long-term, low-maintenance operations. |

Need high-performance PTFE components that are built to last?

The dimpled PTFE bearing is a prime example of how precision engineering solves critical challenges. At KINTEK, we specialize in manufacturing custom PTFE seals, liners, labware, and components for the semiconductor, medical, laboratory, and industrial sectors. Whether you need a prototype or a high-volume order, our focus on precision production ensures reliable performance and extended component life.

Contact us today to discuss how our PTFE expertise can enhance your application's reliability and efficiency.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What temperature range can PTFE seals typically operate in? From Cryogenic -200°C to High-Temp 260°C

- How do PTFE seals perform in chemically aggressive environments? Ensure Unmatched Chemical Resistance

- What are the characteristics of PTFE coatings? Unlock Extreme Performance for Your Components

- What are the benefits of smart monitoring integration in Teflon gland packing? Achieve Predictive Maintenance & Zero Downtime

- What are the most suitable PTFE grades for CNC machined parts? Achieve Optimal Performance and Durability

- In which industries are PTFE bellow mechanical seals commonly used? The Ultimate Solution for Corrosive Fluids

- In which industries are PTFE gaskets commonly used? Ensuring Safety & Purity in Demanding Applications

- What types of chemical substances can PTFE bushings withstand? Ensure Reliability in Aggressive Environments