At its core, Polytetrafluoroethylene (PTFE) is a high-performance fluoropolymer. It is most famous for its exceptional non-stick properties, but its true value comes from a unique combination of characteristics, including extreme temperature stability, near-total chemical inertness, and excellent electrical insulation. These traits make it one of the most versatile problem-solving materials in modern engineering.

The crucial insight is to view PTFE not just as a non-stick coating, but as a surface engineering solution for environments where other materials would quickly fail. Its value lies in its ability to function reliably under extreme chemical, thermal, and electrical stress.

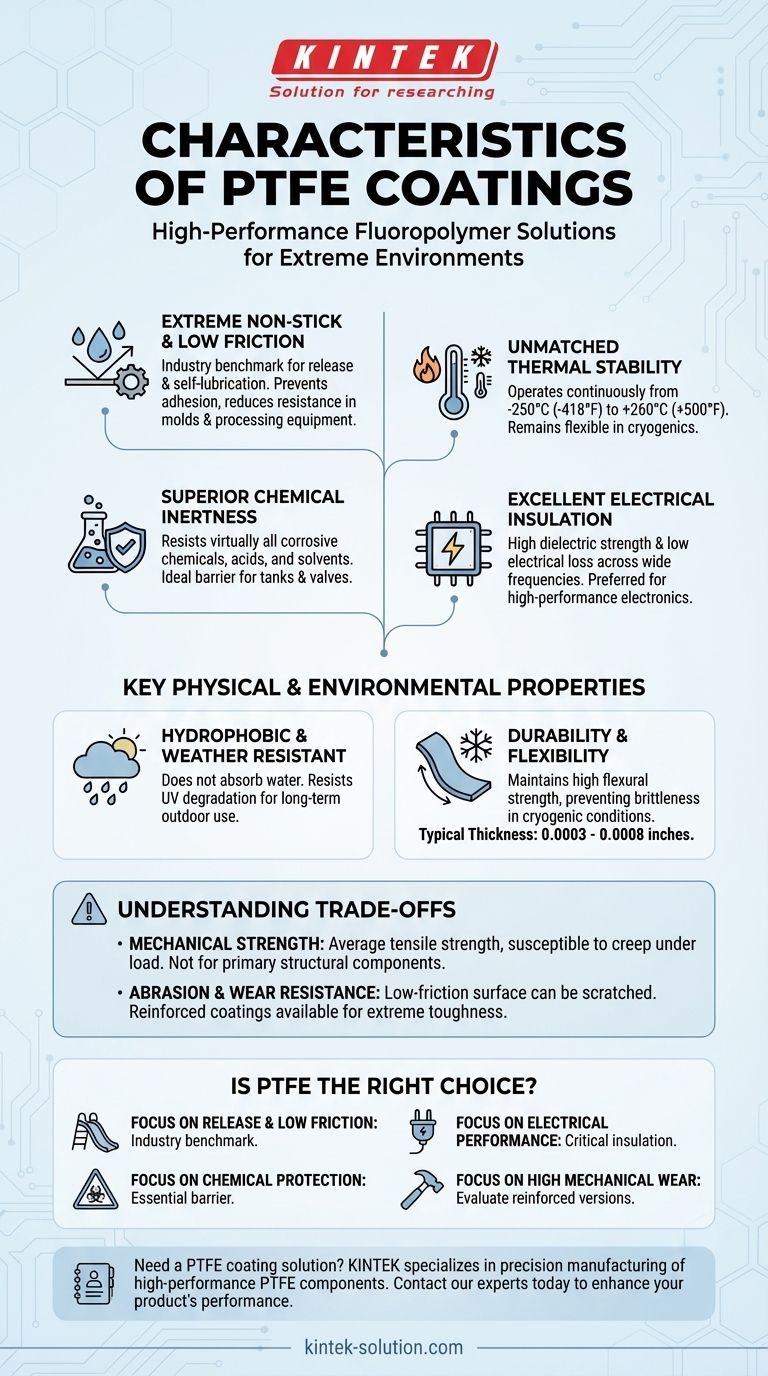

The Defining Characteristics of PTFE

The properties that make PTFE unique are a direct result of its molecular structure, which consists of a chain of carbon atoms completely shielded by fluorine atoms. This strong carbon-fluorine bond is responsible for its remarkable stability.

### Extreme Non-Stick & Low Friction

PTFE has one of the lowest coefficients of friction of any known solid material. This gives it its signature non-stick, or release, capabilities.

This property is critical in applications like molds, food processing equipment, and anywhere a self-lubricating surface is required to prevent material adhesion and reduce resistance.

### Unmatched Thermal Stability

This material demonstrates an incredibly wide operating temperature range.

PTFE coatings can withstand continuous service temperatures up to 260°C (500°F) and remain flexible and functional at cryogenic temperatures as low as -250°C (-418°F) without losing their physical properties.

### Superior Chemical Inertness

Due to its stable chemical structure, PTFE is almost entirely inert and non-reactive.

It offers exceptional resistance to a vast range of corrosive chemicals, acids, and solvents, even at elevated temperatures. This makes it an ideal protective barrier for chemical processing equipment, tanks, and valves.

### Excellent Electrical Insulation

PTFE is an outstanding electrical insulator with high dielectric strength and very low electrical loss.

Its properties remain stable across a wide range of frequencies, making it a preferred material for high-performance cables, insulators, and printed circuit boards, especially in high-frequency applications.

Key Physical and Environmental Properties

Beyond the primary characteristics, several other properties contribute to PTFE's versatility as a coating.

### Hydrophobic and Weather Resistant

PTFE coatings do not absorb water and are highly resistant to degradation from weathering and UV radiation. This ensures long-term performance in outdoor or high-moisture environments.

### Durability and Flexibility

While not known for high tensile strength, PTFE maintains high flexural strength and remains a durable, flexible material even at very low temperatures. This prevents it from becoming brittle in cryogenic conditions.

### Typical Application Thickness

As a coating, PTFE is applied in very thin layers. A typical application thickness ranges from 0.0003 to 0.0008 inches, providing full surface properties without significantly altering component dimensions.

Understanding the Trade-offs

No material is perfect for every application. To use PTFE effectively, it's critical to understand its limitations.

### Mechanical Strength

PTFE has an average tensile strength compared to engineering plastics and is relatively soft. It is not intended for use as a primary structural component and can be susceptible to creep under load.

### Abrasion and Wear Resistance

While durable, its low-friction surface can be vulnerable to scratching and high-wear abrasion. In applications requiring extreme toughness, reinforced PTFE coatings or alternative hard-coat materials may be necessary.

### Application Complexity

Applying a PTFE coating is a precise industrial process. It requires meticulous surface preparation and controlled thermal curing to ensure proper adhesion and performance, making it a process for specialized applicators.

Is PTFE the Right Choice for Your Application?

Your decision to use PTFE should be based on its unique ability to solve problems in extreme environments.

- If your primary focus is release and low friction: PTFE is the industry benchmark for creating non-stick, easy-to-clean, and self-lubricating surfaces.

- If your primary focus is chemical protection: Its profound inertness makes it an essential barrier coating in corrosive chemical environments.

- If your primary focus is electrical performance: Its high dielectric strength is critical for insulating components in demanding, high-frequency electronics.

- If your primary focus is high mechanical wear: You should evaluate reinforced PTFE systems or harder coating materials better suited for abrasion resistance.

Ultimately, understanding these core characteristics allows you to leverage PTFE not just as a coating, but as a strategic solution for demanding engineering challenges.

Summary Table:

| Key Characteristic | Key Benefit / Limitation |

|---|---|

| Extreme Non-Stick & Low Friction | Industry benchmark for release and self-lubrication. |

| Unmatched Thermal Stability | Operates from -250°C to +260°C (-418°F to +500°F). |

| Superior Chemical Inertness | Resists virtually all corrosive chemicals and solvents. |

| Excellent Electrical Insulation | Stable dielectric strength across a wide frequency range. |

| Limitation: Mechanical Strength | Not suitable as a primary structural component; can creep under load. |

| Limitation: Abrasion Resistance | Can be vulnerable to scratching; reinforced versions available. |

Need a PTFE coating solution for extreme environments?

KINTEK specializes in the precision manufacturing and custom fabrication of high-performance PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. We leverage the unique properties of PTFE to solve your most demanding challenges, from prototype development to high-volume production.

Contact our experts today to discuss how our PTFE solutions can enhance your product's performance, durability, and reliability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

People Also Ask

- How are PTFE-lined pipes manufactured? A Guide to Durable, Corrosion-Resistant Piping

- How should seals and gaskets be maintained in PTFE butterfly valves? A Proactive Guide to Prevent Downtime

- What are the overall benefits of spring-energized PTFE seals? Solve Extreme Sealing Challenges

- How does PTFE's soft nature affect surface finish quality during machining? Mastering the Slice, Not Tear, Process

- What are some standard sizes available for PTFE washers? Find the Perfect Fit for Your Application

- What are the main features of PTFE bushings? Unlock Superior Performance in Harsh Environments

- What are the typical applications for low-friction piston seals? Optimize for Smooth Motion & Efficiency

- How do custom Teflon rotary shaft seals contribute to operational efficiency? Maximize Reliability & Cut Costs