The primary features of PTFE bushings are their extremely low coefficient of friction, outstanding resistance to chemicals, and ability to operate across a vast temperature range. These properties make them self-lubricating and exceptionally durable in harsh environments where other materials would quickly fail.

PTFE (Polytetrafluoroethylene) is not just another plastic; it is an engineered polymer chosen for its unique combination of properties. Its value lies in its ability to provide maintenance-free, low-friction performance in conditions involving extreme temperatures, corrosive chemicals, and stringent cleanliness requirements.

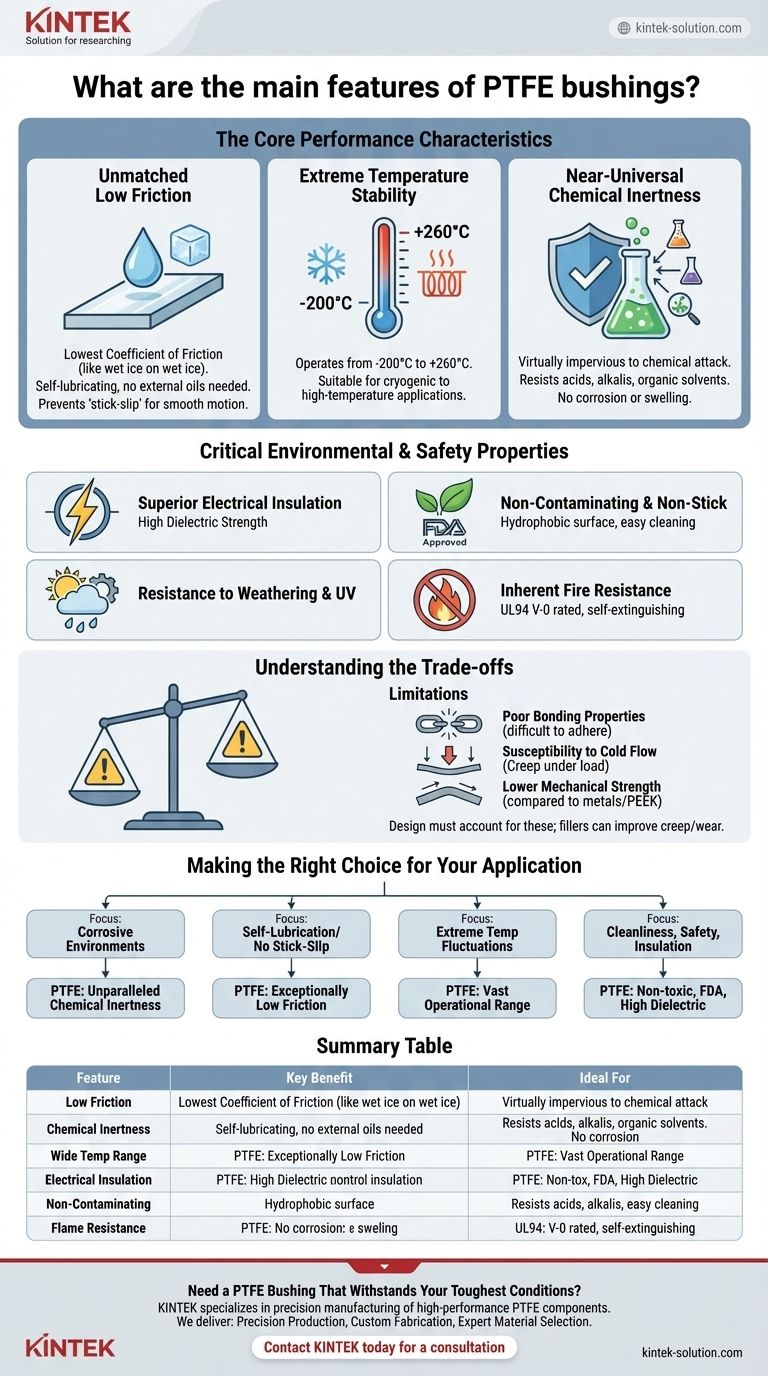

The Core Performance Characteristics

The decision to use a PTFE bushing is almost always driven by three defining performance traits that are difficult to find in a single alternative material.

Unmatched Low Friction

PTFE has the lowest coefficient of friction of any known solid material, often compared to wet ice on wet ice. This makes PTFE bushings inherently self-lubricating.

This eliminates the need for external oils or greases, which is critical in preventing contamination. It also prevents "stick-slip" behavior, ensuring smooth, consistent motion from a complete stop.

Extreme Temperature Stability

PTFE bushings maintain their integrity and performance across an exceptionally wide thermal spectrum, typically from -200°C to +260°C (-328°F to +500°F).

This allows them to be specified for applications ranging from cryogenic equipment to high-temperature industrial processing without degrading.

Near-Universal Chemical Inertness

PTFE is virtually impervious to chemical attack. It is highly resistant to almost all industrial chemicals, acids, alkalis, and organic solvents.

This chemical stiffness ensures the bushing will not corrode, dissolve, or swell when exposed to aggressive substances, guaranteeing a long service life in corrosive environments.

Critical Environmental and Safety Properties

Beyond its core performance, PTFE offers several features that make it a safe and reliable choice for specialized and regulated industries.

Superior Electrical Insulation

PTFE is an excellent electrical insulator with high dielectric strength and high electrical resistance. This property makes it ideal for applications where the bushing must prevent the flow of electricity between components.

Non-Contaminating and Non-Stick Surface

The material is hydrophobic (repels water) and has powerful non-adhesive characteristics. Its non-stick surface facilitates easy cleaning and prevents substances from adhering to it.

This, combined with its inert and non-toxic nature, often results in FDA approval for direct contact with food and use in medical applications.

Resistance to Weathering and UV

PTFE exhibits outstanding tolerance to environmental factors. It is highly resistant to degradation from weathering, UV light, and corrosion, making it suitable for long-term outdoor use.

Inherent Fire Resistance

PTFE is incombustible and does not promote flame spread. It often carries a high flame rating, such as UL94 V-0, meaning it self-extinguishes quickly after the flame source is removed.

Understanding the Trade-offs

While its properties are exceptional, PTFE is not the solution for every application. Understanding its limitations is key to using it effectively.

Poor Bonding Properties

The same non-stick quality that makes PTFE valuable also makes it very difficult to bond to other materials using conventional adhesives. This must be accounted for during the design phase, often requiring mechanical fastening.

Susceptibility to Cold Flow (Creep)

Under sustained load, pure PTFE can be susceptible to "cold flow," or creep, where the material slowly deforms. High-performance PTFE bushings often contain fillers (like glass, carbon, or bronze) to significantly improve their resistance to creep and wear.

Lower Mechanical Strength

Compared to metal bushings or other engineering plastics like PEEK, PTFE has lower compressive strength and rigidity. It is not the ideal choice for extremely high-load, high-impact structural applications without reinforcement.

Making the Right Choice for Your Application

Selecting a PTFE bushing is about matching its unique capabilities to a specific operational challenge.

- If your primary focus is performance in corrosive environments: PTFE is an unparalleled choice due to its near-total chemical inertness.

- If your primary focus is self-lubrication or eliminating stick-slip: PTFE's exceptionally low friction coefficient provides smooth, maintenance-free motion.

- If your primary focus is dealing with extreme temperature fluctuations: The material's vast operational temperature range ensures stability in both cryogenic and high-heat conditions.

- If your primary focus is cleanliness, safety, or electrical insulation: PTFE's non-toxic, non-stick, and high-dielectric properties make it a default choice for food, medical, and electronic applications.

Ultimately, PTFE bushings are specified when the operational environment is too demanding for conventional materials to survive.

Summary Table:

| Feature | Key Benefit | Ideal For |

|---|---|---|

| Low Friction | Self-lubricating, no stick-slip | Precision motion systems |

| Chemical Inertness | Resists acids, alkalis, solvents | Corrosive chemical processing |

| Wide Temp Range | -200°C to +260°C | Cryogenics to high-heat applications |

| Electrical Insulation | High dielectric strength | Electronics, electrical assemblies |

| Non-Contaminating | FDA-approved, non-stick | Medical, food, pharmaceutical industries |

| Flame Resistance | UL94 V-0 rated | Safety-critical environments |

Need a PTFE Bushing That Withstands Your Toughest Conditions?

KINTEK specializes in the precision manufacturing of high-performance PTFE components, including bushings, seals, liners, and custom labware. We serve demanding industries like semiconductor, medical, and industrial processing where material failure is not an option.

We deliver the value you need:

- Precision Production: Consistent quality and performance for reliable operation.

- Custom Fabrication: From initial prototypes to high-volume production runs.

- Expert Material Selection: Guidance on standard or filled PTFE compounds to overcome limitations like creep for your specific load and application.

Let us provide the durable, maintenance-free solution your application requires.

Contact KINTEK today for a consultation to discuss your PTFE component needs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability