Effective maintenance of seals and gaskets in PTFE butterfly valves is a discipline of proactive inspection and timely replacement. This involves regularly checking for any signs of wear, degradation, or damage and replacing these components according to the manufacturer’s schedule, or immediately if any leaks or performance issues are observed.

The core principle is to view seal and gasket maintenance not as an isolated task, but as a critical component of a comprehensive valve integrity program. Focusing only on replacement without considering the valve's operational environment is the most common path to unexpected system failure.

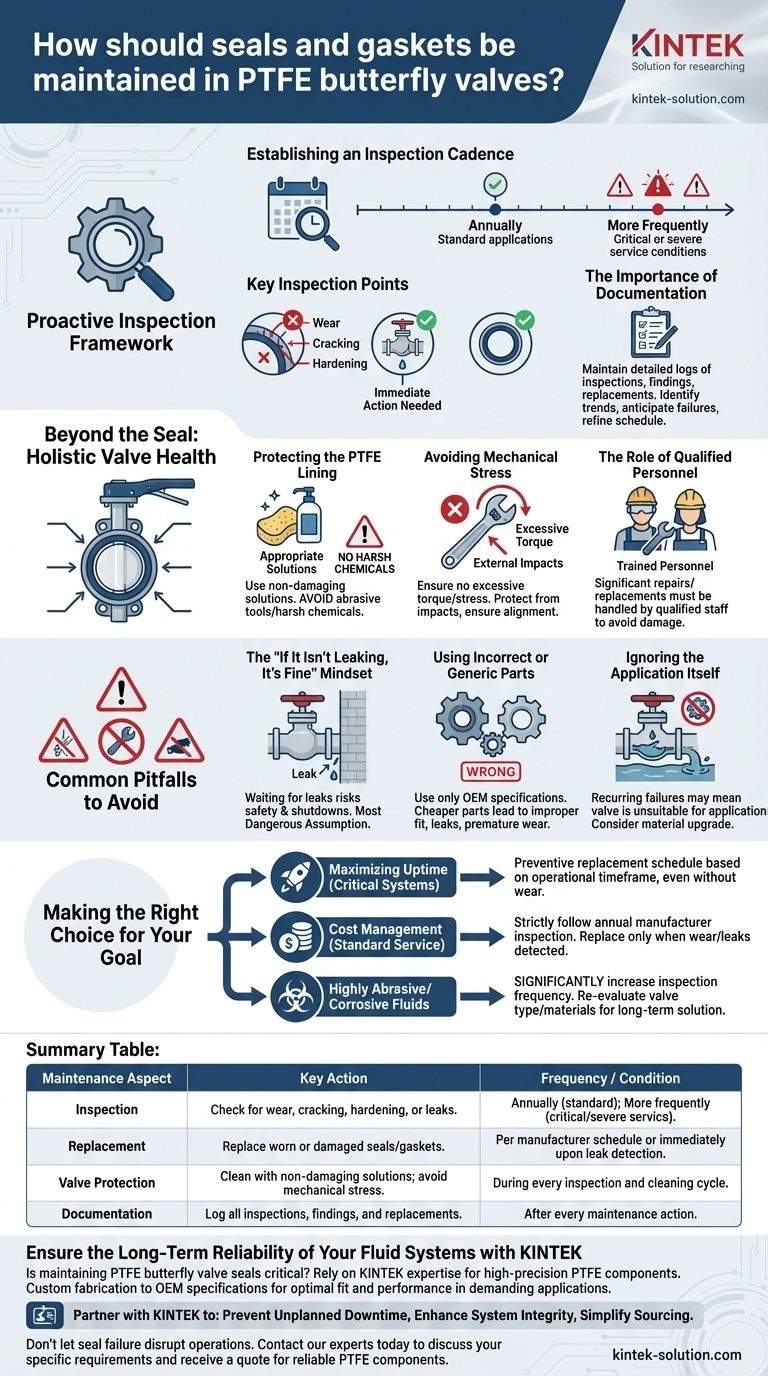

The Proactive Inspection Framework

A robust maintenance plan relies on a consistent and detailed inspection process. This moves you from a reactive "fix-it-when-it-breaks" model to a proactive one that prevents downtime.

Establishing an Inspection Cadence

The frequency of your inspections is dictated by the service conditions.

For standard applications, an inspection should be conducted at least annually.

For critical or severe service conditions, such as those involving highly corrosive fluids or frequent cycling, inspections should be performed much more frequently to ensure system safety and reliability.

Key Inspection Points

During an inspection, your focus should be on identifying early signs of failure.

Look for any visual evidence of wear, cracking, or hardening of the seal and gasket materials. The presence of any leak, however minor, necessitates immediate action.

The Importance of Documentation

Maintain a detailed log of all inspections, findings, and replacements for each valve.

This record-keeping allows you to identify trends, anticipate failures, and refine your maintenance schedule based on real-world performance data rather than generic guidelines.

Beyond the Seal: Holistic Valve Health

The longevity of your seals and gaskets is directly tied to the overall condition of the butterfly valve assembly. Protecting the entire unit is essential.

Protecting the PTFE Lining

The valve's PTFE lining provides its primary corrosion resistance. Its integrity is paramount.

When cleaning is necessary, use only appropriate, non-damaging solutions. Vigorously avoid harsh chemicals or any abrasive tools that could scratch or compromise the lining.

Avoiding Mechanical Stress

Improper operation can cause premature failure of both the valve and its seals.

Ensure the valve is not subjected to excessive torque or mechanical stress beyond its design parameters. This includes protecting it from external impacts and ensuring proper alignment within the pipeline.

The Role of Qualified Personnel

Any significant repairs or part replacements should be handled by trained and qualified personnel.

Improper disassembly or reassembly can easily damage seals or the PTFE lining, leading to immediate leaks and creating more significant problems than the one you set out to solve.

Common Pitfalls to Avoid

Even with a plan, certain misconceptions can undermine your maintenance efforts. Recognizing them is the first step to avoiding costly mistakes.

The "If It Isn't Leaking, It's Fine" Mindset

This is the most dangerous assumption in fluid systems management. Waiting for a visible leak means the seal has already completely failed, risking safety, environmental compliance, and unplanned shutdowns.

Using Incorrect or Generic Parts

Always use seals and gaskets that meet the original manufacturer's specifications. Using cheaper, non-specified parts can lead to improper fits and material incompatibilities, causing leaks and premature wear.

Ignoring the Application Itself

If you experience recurring seal failures, the problem may not be the maintenance schedule but the valve's suitability for the application.

Constantly replacing parts on a valve handling overly abrasive or corrosive fluids is a temporary fix. The long-term solution might be upgrading to a valve constructed from more resilient materials.

Making the Right Choice for Your Goal

Your maintenance strategy should directly align with your system's operational demands and risk tolerance.

- If your primary focus is maximizing uptime in critical systems: Implement a preventive replacement schedule for seals and gaskets based on a set operational timeframe, even without visible wear.

- If your primary focus is cost management in standard service: Adhere strictly to the manufacturer's recommended annual inspection, replacing parts only when wear is detected or leaks occur.

- If you are dealing with highly abrasive or corrosive fluids: Increase inspection frequency significantly and be prepared to re-evaluate if the current valve type and materials are the correct long-term solution.

A disciplined, context-aware maintenance program is your best defense against premature valve failure and system disruption.

Summary Table:

| Maintenance Aspect | Key Action | Frequency / Condition |

|---|---|---|

| Inspection | Check for wear, cracking, hardening, or leaks. | Annually (standard); More frequently (critical/severe service). |

| Replacement | Replace worn or damaged seals/gaskets. | Per manufacturer schedule or immediately upon leak detection. |

| Valve Protection | Clean with non-damaging solutions; avoid mechanical stress. | During every inspection and cleaning cycle. |

| Documentation | Log all inspections, findings, and replacements. | After every maintenance action. |

Ensure the Long-Term Reliability of Your Fluid Systems with KINTEK

Is maintaining the seals and gaskets in your PTFE butterfly valves critical for your semiconductor, medical, laboratory, or industrial operations? Rely on the expertise of KINTEK, a leading manufacturer of high-precision PTFE components.

We specialize in custom fabricating PTFE seals, gaskets, liners, and labware that meet exact OEM specifications, ensuring optimal fit, material compatibility, and performance in demanding applications—from prototypes to high-volume orders.

Partner with KINTEK to:

- Prevent Unplanned Downtime: Get durable, precision-engineered parts that extend maintenance intervals.

- Enhance System Integrity: Ensure compatibility with corrosive or abrasive fluids.

- Simplify Sourcing: Access custom solutions and reliable supply for all your PTFE component needs.

Don't let seal failure disrupt your operations. Contact our experts today to discuss your specific requirements and receive a quote for reliable PTFE components.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- Why is PTFE considered an effective sealing solution for various industries? Discover the Ultimate Material for Demanding Seals

- What property does graphite filler provide to PTFE? Achieve Superior Self-Lubrication and Low Friction

- Why is Teflon used as an insulator? Unmatched Signal Integrity & Chemical Resistance

- What is the coefficient of friction for these o-rings? Don't Be Misled by a Single Number

- Which type of seal is best suited for high-speed applications? PTFE Seals for Speeds Up to 35 m/s

- What are the limitations of machining Teflon? Overcoming Burrs, Creep, and Thermal Instability

- Why are PTFE energized seals a preferred choice for aerospace engineers? Ensure Reliability in Extreme Conditions

- What are common applications for unfilled PTFE sheets? Leverage Chemical Inertness & Purity