In the unforgiving environment of aerospace, component failure is not an option. PTFE energized seals are a preferred choice for engineers because they offer a unique combination of material and mechanical properties that guarantees performance across an extreme range of temperatures, pressures, and chemical exposures where conventional seals would fail. Their design ensures consistent, reliable sealing in critical systems from cryogenic fuel lines to high-temperature actuators.

The core reason for their adoption is not just one superior feature, but their ability to solve multiple, simultaneous engineering challenges. A PTFE energized seal provides a solution that remains stable and effective in the dynamic, hostile conditions inherent to flight and space exploration.

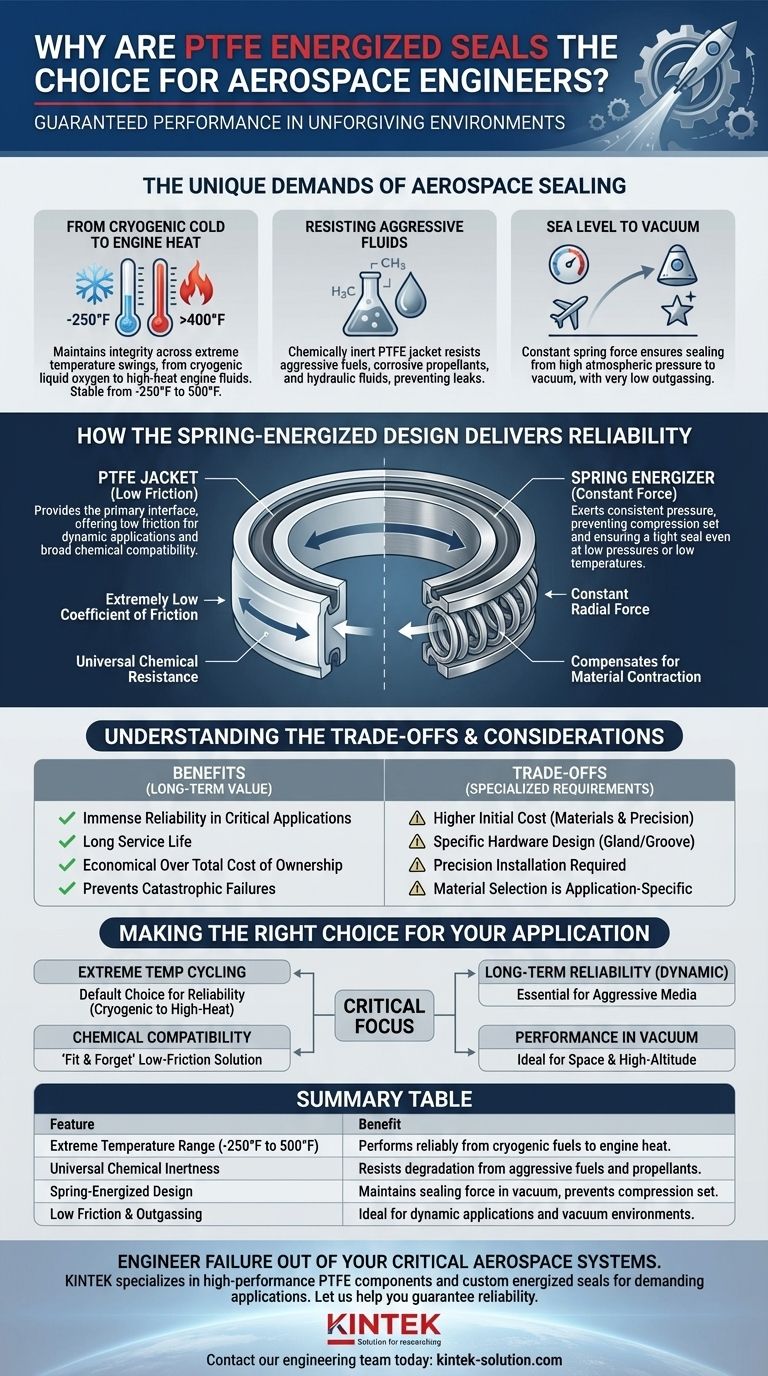

The Unique Demands of Aerospace Sealing

Aerospace applications subject components to conditions that are orders of magnitude more severe than in most industrial settings. A seal must perform flawlessly under a punishing combination of factors.

From Cryogenic Cold to Engine Heat

Aerospace systems must operate through massive temperature swings. A seal might be exposed to cryogenic liquid oxygen or hydrogen at temperatures below -250°F (-157°C) one moment and high-temperature hydraulic fluids or engine heat well above 400°F (204°C) the next.

PTFE energized seals maintain their integrity and sealing force across this entire spectrum, from cryogenic conditions up to 500°F (260°C). Unlike traditional elastomers that become brittle when frozen or degrade at high temperatures, PTFE remains stable.

Resisting Aggressive Aerospace Fluids

Seals in fuel systems, propulsion lines, and hydraulic actuators are in constant contact with aggressive chemicals. These include jet fuels, corrosive rocket propellants, and specialized hydraulic fluids that can quickly degrade standard sealing materials.

PTFE is almost entirely chemically inert. It resists acids, solvents, and other corrosive fluids, ensuring that the seal does not swell, shrink, or break down over its service life, preventing catastrophic leaks.

Maintaining Integrity from Sea Level to Vacuum

An aircraft climbs from sea-level atmospheric pressure to the near-vacuum of high altitudes. This creates significant pressure differentials that can compromise a seal. Furthermore, in the vacuum of space, materials can "outgas," releasing trapped volatiles that can contaminate sensitive optical or electronic equipment.

The spring in an energized seal provides a constant mechanical force, ensuring the seal remains engaged even at very low pressures or in a vacuum. PTFE also has very low outgassing properties, making it ideal for space-bound applications.

How the Spring-Energized Design Delivers Reliability

The genius of this component lies in the synergy between its two main parts: the PTFE jacket and the internal spring energizer. They work together to overcome the limitations of each material alone.

The Role of the PTFE Jacket

The seal jacket is machined from a specific grade of Polytetrafluoroethylene (PTFE). This material provides the primary interface with the operating environment.

Its key contributions are its extremely low coefficient of friction, broad temperature stability, and near-universal chemical resistance. The low friction is critical in dynamic applications like actuators, as it reduces wear and tear, minimizes energy loss, and allows for smooth operation without lubrication.

The Function of the Spring Energizer

PTFE itself is not a very elastic material; it can take a compression set and lose its sealing force. The internal metallic spring is the "energizer" that solves this problem.

The spring exerts a constant, consistent radial force on the PTFE jacket, pressing it against the sealing surfaces. This ensures a tight seal even when system pressure is low and compensates for any material contraction at low temperatures or wear over the seal's life.

Eliminating "Compression Set" Failure

A common failure mode for traditional elastomeric O-rings is compression set. Over time and under thermal cycling, the elastomer loses its ability to rebound to its original shape, creating a leak path.

The spring-energized design completely avoids this issue. The spring, not the jacket material, provides the resilient sealing force, guaranteeing long-term, predictable performance and significantly extending maintenance intervals.

Understanding the Trade-offs and Considerations

While highly effective, PTFE energized seals are a specialized component. Acknowledging their specific requirements is key to successful implementation.

Higher Initial Cost

Compared to a standard O-ring, a PTFE energized seal is a more expensive component. This is due to the higher cost of the raw materials and the precision machining required to manufacture them.

However, this cost must be weighed against the total cost of ownership. The immense reliability and long service life often make them more economical in critical applications where seal failure would lead to costly repairs or mission failure.

Installation and Hardware Design

These are not simple drop-in replacements for every type of seal. The hardware, specifically the gland or groove the seal sits in, must be designed to precise specifications.

Surface finish and edge breaks are critical to prevent damage to the PTFE jacket during installation and to ensure proper performance. Improper installation is a leading cause of premature failure for these precision components.

Material Selection is Application-Specific

There is no single "best" PTFE energized seal. The specific blend of the PTFE jacket and the material of the spring (e.g., stainless steel, Elgiloy) must be carefully selected based on the exact temperature, pressure, and chemical environment of the application.

Making the Right Choice for Your Application

Selecting the right seal is a critical design decision. Use the following points as a guide for specifying a PTFE energized seal.

- If your primary focus is extreme temperature cycling: PTFE energized seals are the default choice for reliability in systems that move between cryogenic temperatures and high-heat operation.

- If your primary focus is chemical compatibility: Their near-total chemical inertness makes them essential for sealing aggressive propellants, hydraulic fluids, and other challenging media.

- If your primary focus is long-term reliability in dynamic systems: The low-friction, wear-resistant design provides a "fit and forget" solution for actuators and rotary joints, justifying the investment.

- If your primary focus is performance in a vacuum: The combination of positive mechanical force from the spring and low outgassing properties makes these seals ideal for space and high-altitude systems.

Ultimately, specifying a PTFE energized seal is a strategic decision to engineer failure out of a critical system.

Summary Table:

| Feature | Benefit for Aerospace |

|---|---|

| Extreme Temperature Range (-250°F to 500°F) | Performs reliably from cryogenic fuels to engine heat. |

| Universal Chemical Inertness | Resists degradation from aggressive fuels, propellants, and hydraulic fluids. |

| Spring-Energized Design | Maintains sealing force in vacuum and compensates for wear, preventing compression set. |

| Low Friction & Outgassing | Ideal for dynamic applications and vacuum environments like space systems. |

Engineer failure out of your critical aerospace systems.

At KINTEK, we specialize in the precision manufacturing of high-performance PTFE components, including custom energized seals for the most demanding applications. Our expertise in material science and custom fabrication ensures your seals are optimized for your specific temperature, pressure, and chemical requirements—from prototypes to high-volume production.

Let us help you guarantee reliability where it matters most.

Contact our engineering team today to discuss your project's sealing challenges.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry