The primary limitations of machining Teflon (PTFE) stem from its unique material properties. Its inherent softness leads to burring and makes it difficult to clamp securely, while its high thermal expansion rate and tendency to "creep" or deform under stress make achieving and holding tight tolerances a significant challenge.

Machining Teflon is less about overcoming a single obstacle and more about managing a set of interconnected material behaviors. Success requires accounting for its softness, thermal instability, and slippery nature at every stage of the process, from workholding to the final cut.

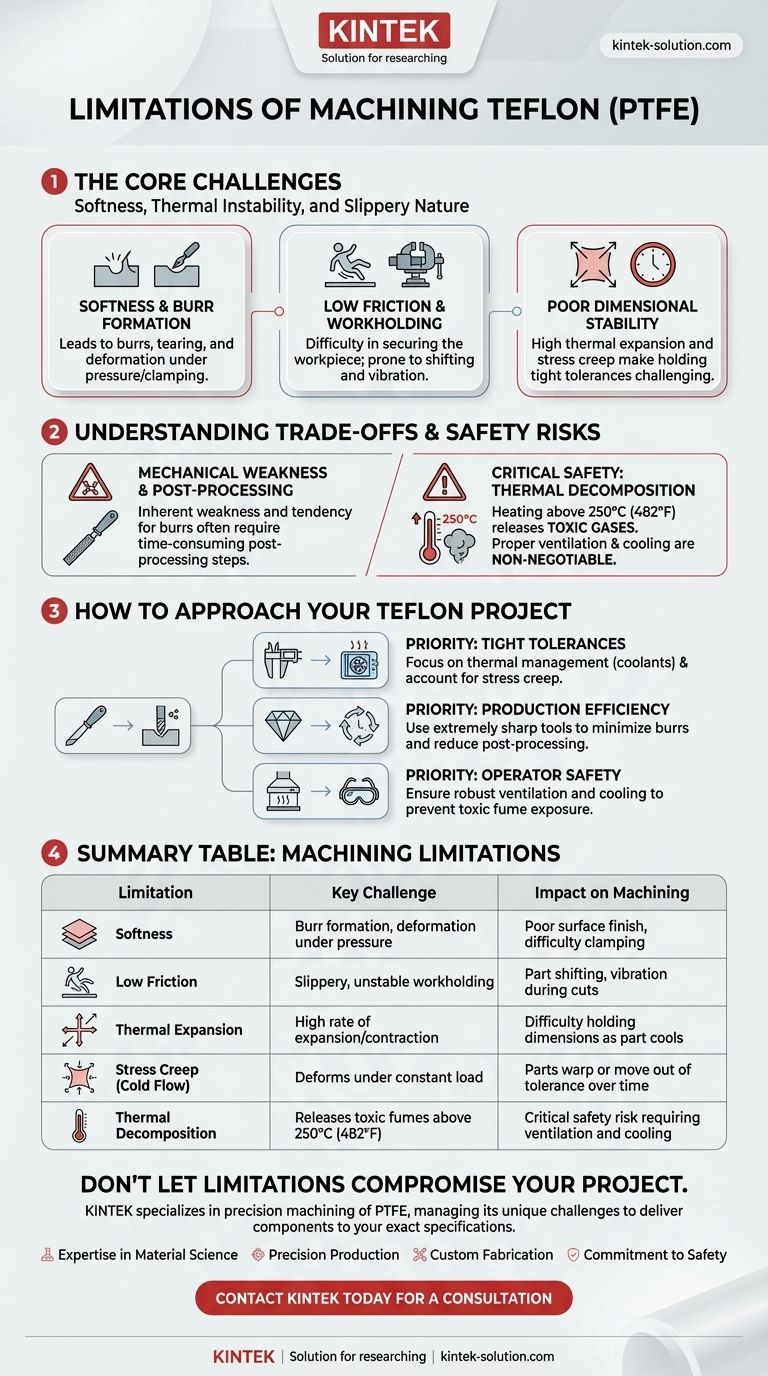

The Core Challenges of Machining Teflon

To effectively machine Teflon, one must first understand the fundamental properties that make it distinct from metals or even other plastics. These properties are the source of its limitations.

The Problem of Softness and Burr Formation

Teflon is an exceptionally soft material. This softness means that instead of shearing cleanly, the material often deforms or tears during cutting, leading to the formation of burrs on the finished part.

This softness also makes the material susceptible to deformation under the pressure of cutting tools or clamping fixtures. Applying too much force can easily crush or distort the workpiece, compromising dimensional accuracy.

Low Friction and Workholding Instability

Teflon's famously low coefficient of friction makes it very slippery. While this is a benefit in many applications, it creates a significant challenge in machining: holding the workpiece securely.

The material can easily shift or vibrate in a clamp or vise if not held properly. Over-tightening to compensate can deform the soft material, creating a difficult trade-off between stability and part integrity.

Poor Dimensional Stability

This is perhaps the most critical limitation. Teflon's dimensions can change due to two main factors: thermal expansion and stress creep.

- High Thermal Expansion: Teflon expands and contracts with temperature changes far more than most materials. The heat generated during machining can cause the part to grow, only for it to shrink back down as it cools, making it difficult to hit precise target dimensions.

- Stress Creep (Cold Flow): Teflon will slowly deform over time when under a constant load, even at room temperature. This "creep" can warp parts and cause them to move out of tolerance long after they have been machined.

Difficulty Achieving Tight Tolerances

The combination of softness, thermal expansion, and stress creep makes holding tight tolerances the ultimate challenge. Each of these factors can independently ruin the accuracy of a part, and they often work in concert during the machining process.

Understanding the Trade-offs and Safety Risks

Working with Teflon requires accepting its inherent limitations and being aware of potential hazards that are not present with other common materials.

Mechanical Weakness is Inherent

While an excellent material for low-friction and chemical-resistant applications, Teflon has poor mechanical properties. It is not strong or rigid, which must be considered during the design phase. Its machinability issues are a direct result of these inherent weaknesses.

Post-Processing is Often Necessary

Due to the tendency for burr formation, a post-processing step is often required to deburr the part and achieve the desired final finish. This adds time and cost to the manufacturing process.

Critical Safety: Managing Thermal Decomposition

This is a non-negotiable safety consideration. If Teflon is heated above 250°C, it begins to decompose and can release toxic gases.

It is absolutely critical to manage heat generation during machining. This is achieved through proper ventilation, sharp tooling, appropriate cutting speeds, and often the use of cooling systems to keep the material and cutting zone at a safe temperature.

How to Approach Your Teflon Machining Project

Choosing the right strategy depends entirely on your project's specific requirements.

- If your primary focus is achieving the tightest possible tolerances: You must prioritize thermal management with coolants and account for stress creep in your design and inspection processes.

- If your primary focus is production efficiency: Use extremely sharp tools, potentially diamond-tipped, to minimize burrs and reduce the need for extensive post-processing.

- If your primary focus is operator safety: Ensure robust ventilation and cooling systems are in place to prevent any risk of thermal decomposition and toxic fume exposure.

Ultimately, successful Teflon machining comes from respecting the material's limitations rather than fighting against them.

Summary Table:

| Limitation | Key Challenge | Impact on Machining |

|---|---|---|

| Softness | Burr formation, deformation under pressure | Poor surface finish, difficulty clamping |

| Low Friction | Slippery, unstable workholding | Part shifting, vibration during cuts |

| Thermal Expansion | High rate of expansion/contraction | Difficulty holding dimensions as part cools |

| Stress Creep (Cold Flow) | Deforms under constant load | Parts warp or move out of tolerance over time |

| Thermal Decomposition | Releases toxic fumes above 250°C (482°F) | Critical safety risk requiring ventilation and cooling |

Don't let Teflon's limitations compromise your project.

At KINTEK, we specialize in precision machining of PTFE (Teflon) for the semiconductor, medical, laboratory, and industrial sectors. We understand the unique challenges of this material and have the expertise to manage softness, thermal instability, and stress creep to deliver components that meet your exact specifications.

Our value to you:

- Expertise in Material Science: We select the right tools and techniques to minimize burrs and manage heat.

- Precision Production: We account for thermal expansion and creep to hold tight tolerances.

- Custom Fabrication: From prototypes to high-volume orders, we deliver custom PTFE seals, liners, and labware.

- Commitment to Safety: We prioritize safe machining practices to prevent thermal decomposition.

Let's discuss your specific application and requirements. Contact KINTEK today for a consultation on your custom PTFE components.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials