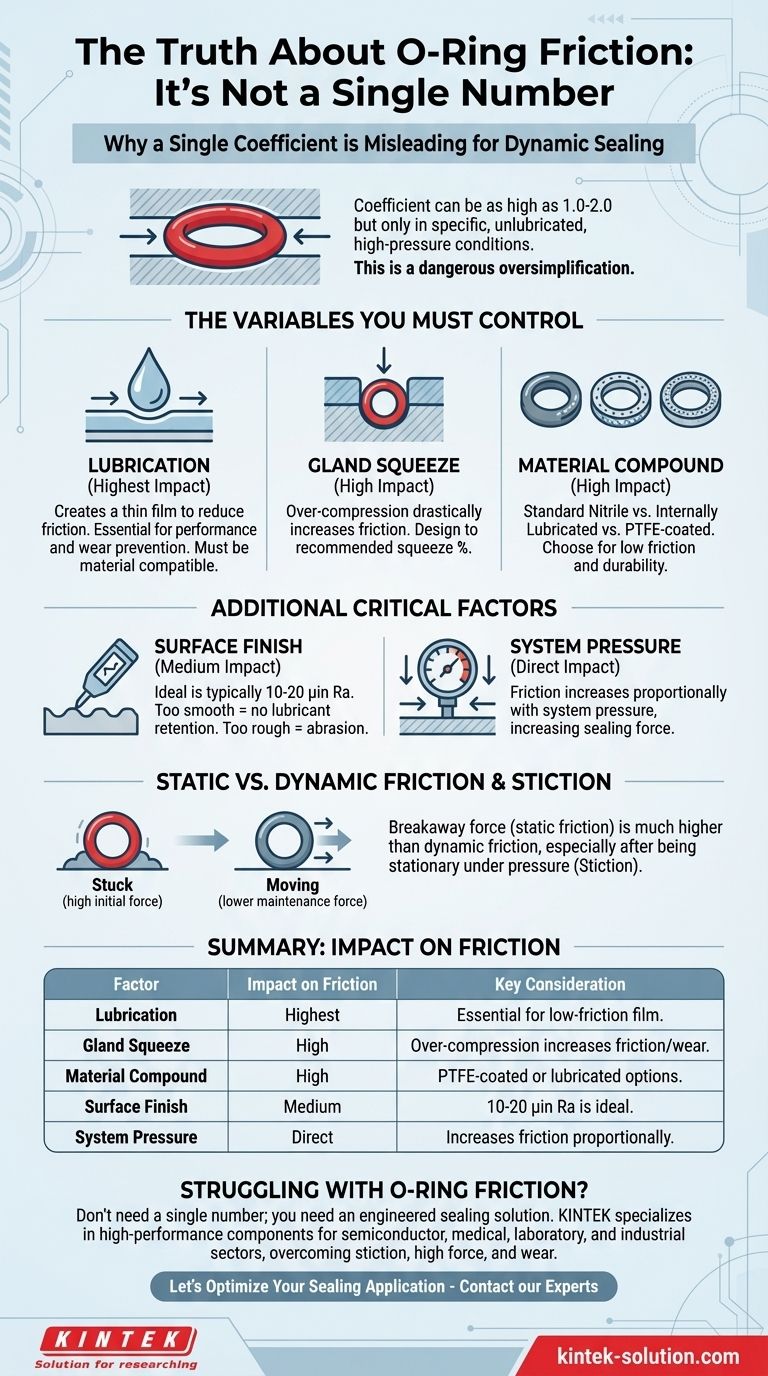

For an O-ring, the coefficient of friction can be as high as 1.0 to 2.0, but only under very specific, unlubricated, and high-pressure conditions. This single value is profoundly misleading because the actual friction you will experience is not a simple material property. It is a direct result of your entire system's design and operating environment.

The concept of a single "coefficient of friction" for an O-ring is a dangerous oversimplification. Instead of seeking one number, you must focus on controlling the key system variables—lubrication, material, compression, and surface finish—to manage the actual frictional force in your application.

Why a Single Friction Value Fails

Friction in a sealing application is a dynamic output of the system, not a static property of the rubber. Relying on a single textbook number without understanding the context will lead to incorrect calculations and potential design failure.

Static vs. Dynamic Friction (Breakaway Force)

The force needed to start motion (static friction) is often much higher than the force needed to maintain it (dynamic friction). This phenomenon, known as stiction or breakaway friction, is especially pronounced in O-rings that have been stationary under pressure for a period of time.

The Overwhelming Impact of Lubrication

Lubrication is the single most important factor. An unlubricated O-ring sliding against a dry metal surface will have drastically higher friction and wear compared to one with even a thin film of grease or system fluid.

How Pressure Creates Friction

Friction is the normal force multiplied by the coefficient of friction. In an O-ring application, the normal force comes from two sources: the initial mechanical squeeze from the gland design and the system pressure acting on the O-ring, which further energizes the seal against the hardware. As system pressure increases, the sealing force and the resulting friction increase proportionally.

Material Compound Is a Critical Choice

Different elastomer compounds have inherently different frictional properties. A standard Nitrile (Buna-N) O-ring will have a higher coefficient of friction than an internally lubricated silicone or a PTFE-coated O-ring designed specifically for dynamic applications.

Key Factors You Can Actually Control

Instead of searching for a single number, a successful design focuses on managing the variables that produce the frictional force.

Specify the Gland Design (Squeeze)

Over-compressing an O-ring is a common mistake. It dramatically increases friction and wear without significantly improving sealing capability, especially in a pressurized system. Always design to the manufacturer's recommended squeeze percentage for your application.

Define the Hardware Surface Finish

The finish of the moving hardware is critical. A surface that is too rough (high Ra value) will abrade the seal like sandpaper. A surface that is too smooth (low Ra value) will not retain lubricant, leading to high friction. Dynamic applications typically require a finish between 10-20 µin Ra.

Choose the Right Lubricant

The lubricant's primary job is to create a thin film separating the O-ring from the hardware. It must be compatible with the O-ring material to prevent swelling or degradation and must have the correct viscosity for the application's speed and temperature.

Select a Low-Friction Material

If minimizing friction is a primary design driver, consider advanced solutions. Internally lubricated compounds have additives that bloom to the surface over time, while PTFE coatings provide a durable, low-friction surface on the O-ring itself.

Understanding the Trade-offs

Optimizing for low friction often involves balancing competing requirements.

Sealing Integrity vs. Friction

A higher squeeze creates a more robust seal at very low pressures but guarantees higher friction and reduced cycle life. You must find the correct balance for your specific operating pressure.

Lubricant Compatibility vs. Performance

The best-performing lubricant is useless if it causes the O-ring material to swell, shrink, or chemically break down. Compatibility must be your first priority when selecting a lubricant.

Cost vs. Performance

Low-friction materials, special coatings, and tightly controlled surface finishes all add cost. You must weigh the expense against the required performance, efficiency, and desired service life of the component.

Making the Right Choice for Your Application

Use your primary engineering goal to guide your design decisions.

- If your primary focus is minimizing actuation force: Prioritize proper lubrication and select an O-ring material known for low friction, ensuring you don't over-compress the seal in the gland design.

- If your primary focus is long-term durability in a dynamic application: Concentrate on the surface finish of the mating hardware and ensure consistent lubrication to prevent abrasion and wear.

- If your primary focus is preventing stick-slip (stiction): Choose an elastomer with a low difference between static and dynamic friction, or consider a seal design that incorporates a PTFE element.

Ultimately, managing O-ring friction is an exercise in thoughtful system design, not a search for a single data point.

Summary Table:

| Factor | Impact on Friction | Key Consideration |

|---|---|---|

| Lubrication | Highest Impact | Essential for creating a low-friction film; must be material compatible. |

| Gland Squeeze | High Impact | Over-compression drastically increases friction and wear. |

| Material Compound | High Impact | PTFE-coated or internally lubricated compounds offer lowest friction. |

| Surface Finish | Medium Impact | A finish of 10-20 µin Ra is typically ideal for dynamic seals. |

| System Pressure | Direct Impact | Friction increases proportionally with pressure. |

Struggling with O-ring friction in your design?

You don't need a single number; you need a sealing solution engineered for your specific system. At KINTEK, we specialize in high-performance PTFE components, including custom O-rings and seals designed for low friction and long service life in demanding applications.

We help engineers in the semiconductor, medical, laboratory, and industrial sectors overcome challenges like stiction, high actuation force, and premature wear. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures you get a seal that balances performance, durability, and cost.

Let's optimize your sealing application. Contact our experts today for a consultation.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs