At its core, adding graphite filler to Polytetrafluoroethylene (PTFE) transforms the material by significantly reducing its coefficient of friction and imparting a self-lubricating property. This enhancement makes the resulting compound ideal for applications requiring smooth, low-wear movement without external lubricants.

The primary function of graphite in PTFE is to serve as a dry lubricant. While standard PTFE is already slippery, graphite elevates this property, creating a material optimized for dynamic seals, bearings, and other components where minimizing friction is the critical performance goal.

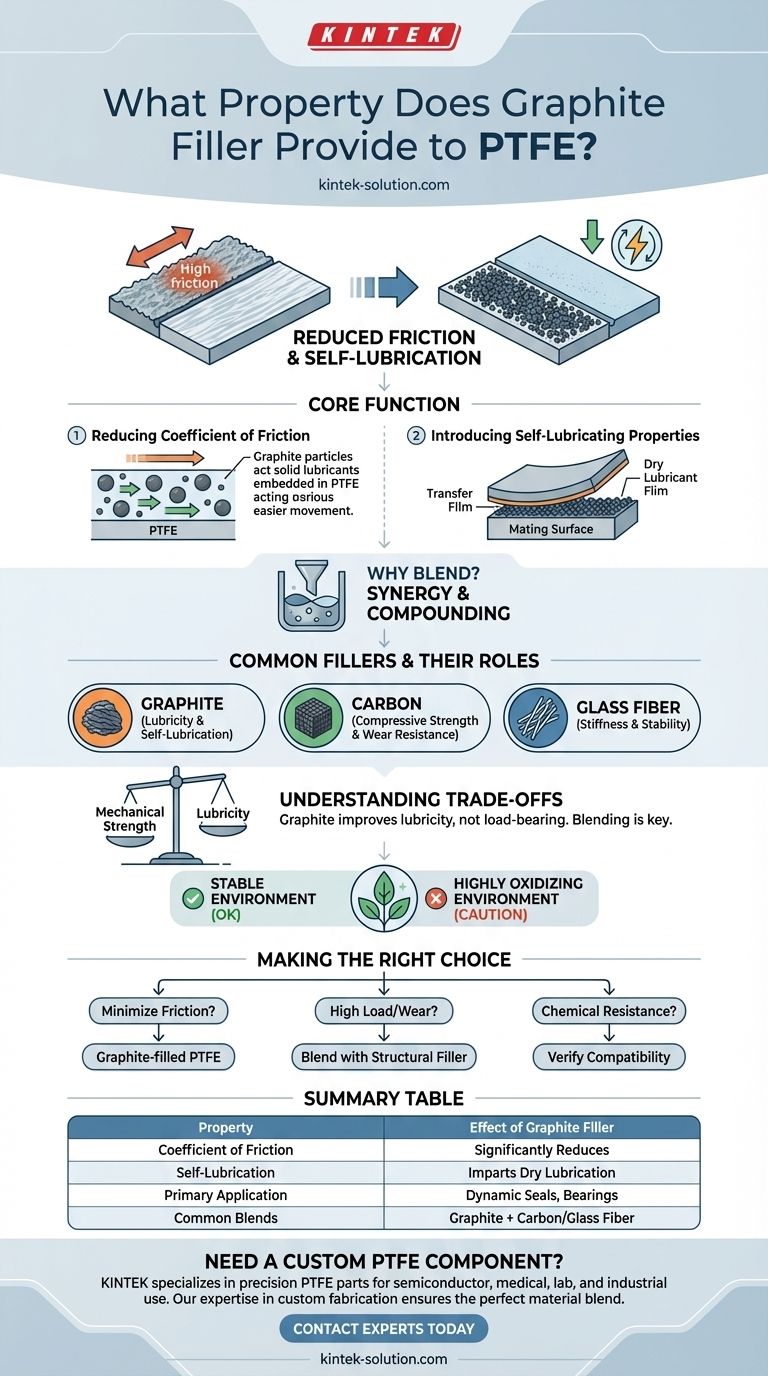

The Core Function of Graphite in PTFE

To understand why graphite is a valuable additive, we must look at how it fundamentally changes PTFE's behavior in moving applications.

Reducing the Coefficient of Friction

Graphite particles act as solid lubricants embedded within the PTFE matrix. This structure allows surfaces to slide against the graphite-filled PTFE with significantly less resistance.

Practically, this means less energy is required to initiate and sustain movement, reducing operational costs and improving the efficiency of mechanical systems.

Introducing Self-Lubricating Properties

The term "self-lubricating" means the material provides its own lubrication at the wear interface. As the component operates, a thin transfer film of PTFE and graphite is deposited on the mating surface.

This film creates an incredibly low-friction interface, allowing the system to run smoothly in dry conditions where liquid lubricants are impractical or undesirable. This property is crucial for reducing long-term wear.

Why Graphite is Often Part of a Blend

While graphite is an excellent lubricant, it is rarely used as the sole filler in high-performance PTFE applications. It is most effective when compounded with other materials.

The Principle of Compounding

Fillers are chosen to create a synergistic effect, where the final material possesses a balance of properties superior to any single component.

A manufacturer will create a specific "grade" of filled PTFE by combining different fillers to meet the precise demands of an application, such as load, speed, and temperature.

The Role of Other Common Fillers

Graphite is frequently blended with fillers like carbon or glass fiber. While graphite provides lubricity, these other fillers are added to improve different mechanical properties.

For example, carbon can increase compressive strength and wear resistance, while glass can enhance stiffness and dimensional stability. This combination creates a material that is both low-friction and mechanically robust.

Understanding the Trade-offs

Choosing a filled PTFE is an exercise in balancing performance characteristics. No single filler solves every problem.

Mechanical Strength vs. Lubricity

Graphite's primary benefit is lubrication. It does not add the same level of compressive strength or creep resistance as fillers like carbon or bronze.

Therefore, in a high-load application, using only graphite-filled PTFE could lead to premature failure. This is precisely why it is often blended with more structurally reinforcing fillers.

Environmental Compatibility

The choice of filler must always be cross-referenced with the application's environment. While PTFE itself is nearly inert, fillers can have different chemical compatibilities.

Graphite is generally stable but may not be suitable for highly oxidizing environments where a different filler, or unfilled PTFE, might be required.

Making the Right Choice for Your Application

Selecting the correct material depends entirely on the primary challenge you need to solve.

- If your primary focus is minimizing friction in a dry-running system: A PTFE compound containing graphite is an excellent starting point due to its self-lubricating qualities.

- If your primary focus is withstanding high mechanical loads or abrasive wear: Ensure the PTFE blend also includes a structural filler like carbon or glass to provide the necessary strength.

- If your primary focus is chemical resistance: Always verify the compatibility of all filler materials, not just the PTFE base, with any chemicals present in the operating environment.

Ultimately, understanding how individual fillers contribute to the final compound empowers you to select the precise material for optimal performance.

Summary Table:

| Property | Effect of Graphite Filler |

|---|---|

| Coefficient of Friction | Significantly Reduces |

| Self-Lubrication | Imparts Dry Lubrication |

| Primary Application | Dynamic Seals, Bearings |

| Common Blends | Graphite + Carbon or Glass Fiber |

Need a custom PTFE component with optimized friction and wear properties?

At KINTEK, we specialize in precision manufacturing of PTFE components like seals, liners, and labware for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures you get the perfect material blend, whether it's graphite-filled for superior lubrication or a compound with other fillers for enhanced strength and stability.

Contact our experts today to discuss your application requirements and receive a tailored solution that boosts performance and efficiency.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments