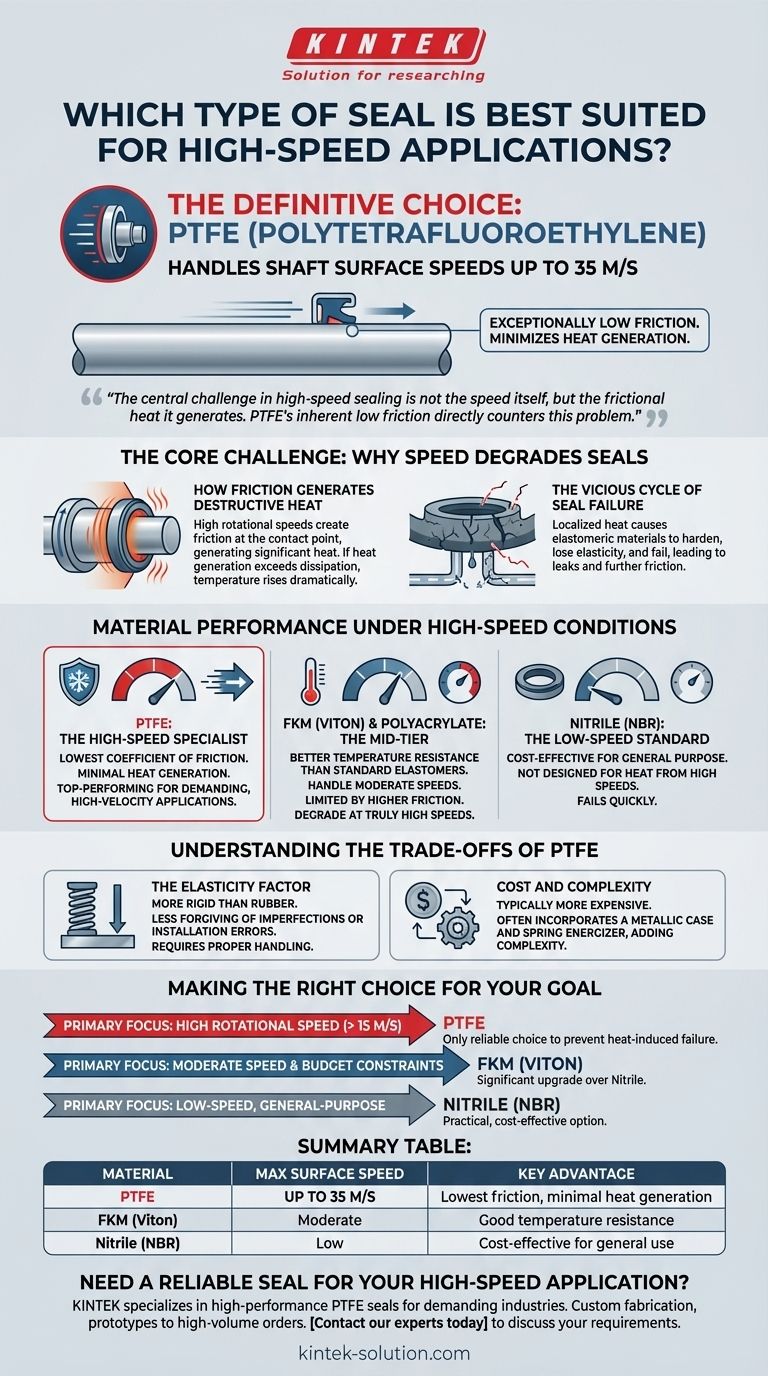

For high-speed applications, the definitive material choice for a seal is Polytetrafluoroethylene (PTFE). Its unique properties allow it to handle shaft surface speeds up to 35 m/s, far exceeding the capabilities of traditional elastomeric seals like Nitrile, Polyacrylate, or even FKM (Viton). The primary reason for its superiority is its exceptionally low friction, which minimizes heat generation at the sealing point.

The central challenge in high-speed sealing is not the speed itself, but the frictional heat it generates. PTFE's inherent low friction directly counters this problem, preventing the heat buildup that causes other materials to harden, crack, and fail prematurely.

The Core Challenge: Why Speed Degrades Seals

At high rotational speeds, the contact point between the seal lip and the shaft becomes a major source of friction. Understanding this dynamic is key to selecting the right material.

How Friction Generates Destructive Heat

Every rotation creates friction between the seal lip and the shaft. As speed increases, this friction generates significant heat, which must be dissipated.

If the heat is generated faster than the system can remove it, the temperature at the seal lip will rise dramatically.

The Vicious Cycle of Seal Failure

This localized heat is the primary cause of failure in high-speed applications. It causes elastomeric (rubber-like) materials to lose their essential properties, becoming brittle and hard.

This degradation compromises the seal's ability to follow the shaft, leading to leaks. Furthermore, the increased heat can break down the lubricant, leading to even more friction and accelerating the failure process.

Material Performance Under High-Speed Conditions

Different materials have vastly different tolerances for the heat and friction generated by high speeds. Their performance can be ranked on a clear hierarchy.

PTFE: The High-Speed Specialist

Polytetrafluoroethylene (PTFE) is a polymer with one of the lowest coefficients of friction of any solid. This means it slides against the rotating shaft with minimal resistance.

Because it generates very little frictional heat, it protects both itself and the lubricant from thermal damage. This makes it the top-performing choice for demanding, high-velocity applications.

FKM (Viton) and Polyacrylate: The Mid-Tier

Materials like FKM and Polyacrylate offer better temperature resistance than standard elastomers. They can handle moderate speeds where a basic seal would quickly fail.

However, they are still fundamentally limited by higher friction coefficients compared to PTFE. At truly high speeds, they will still generate enough heat to eventually degrade.

Nitrile (NBR): The Low-Speed Standard

Nitrile is an excellent, cost-effective material for general-purpose, low-speed applications. It is not designed to dissipate the heat generated by high rotational speeds and will fail very quickly in that environment.

Understanding the Trade-offs

While PTFE is superior for speed, it is not the default choice for every application. Its unique properties come with practical considerations.

The Elasticity Factor

PTFE is a much more rigid material than traditional elastomers like Nitrile. It lacks the "memory" and elasticity of rubber.

This means PTFE seals can be less forgiving of shaft imperfections or installation errors. Proper handling and installation techniques are critical to ensure a reliable seal.

Cost and Complexity

PTFE seals are typically more expensive than their standard elastomeric counterparts due to material and manufacturing costs.

Their design often incorporates a metallic case and a spring energizer to provide the initial sealing force, which adds to the complexity compared to a simple molded rubber seal.

Making the Right Choice for Your Goal

Your selection should be based on a clear understanding of your application's operational demands and constraints.

- If your primary focus is high rotational speed (above 15 m/s): PTFE is the only reliable choice to prevent heat-induced failure and ensure long-term performance.

- If your primary focus is moderate speed with budget constraints: FKM (Viton) provides a significant performance upgrade over Nitrile and can be a suitable mid-range solution.

- If your primary focus is a low-speed, general-purpose system: A standard Nitrile seal remains the most practical and cost-effective option.

Ultimately, choosing the right seal is about matching the material's thermal properties to the rotational demands of your system.

Summary Table:

| Material | Max Surface Speed | Key Advantage |

|---|---|---|

| PTFE | Up to 35 m/s | Lowest friction, minimal heat generation |

| FKM (Viton) | Moderate | Good temperature resistance |

| Nitrile (NBR) | Low | Cost-effective for general use |

Need a reliable seal for your high-speed application?

KINTEK specializes in manufacturing high-performance PTFE seals and components for demanding industries like semiconductor, medical, and laboratory equipment. Our precision-engineered PTFE seals are designed to handle extreme speeds while minimizing friction and heat buildup, ensuring long-lasting performance and preventing costly downtime.

We offer custom fabrication from prototypes to high-volume orders, ensuring a perfect fit and optimal performance for your specific needs.

Contact our experts today to discuss your high-speed sealing requirements and get a solution tailored to your application.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What benefits do PTFE expansion bellows offer in water treatment facilities? Enhance System Reliability & Reduce Costs

- What are the advantages of using Teflon-lined equipment in chemical processing? Ensure Purity & Durability

- What are the key features of PTFE sliding elastomeric bearings? Essential for Bridge and Structural Movement

- What is the advantage of PTFE's self-lubricating properties in shaft seals? Achieve Reliable, Maintenance-Free Performance

- What are the common applications of PTFE diaphragms in the Chinese market? Key Uses in Chemical, Pharma & Semiconductor

- How are custom PTFE parts used in the automotive sector? Enhance Vehicle Performance & Durability

- What material is used to make PTFE V-Rings? Pure PTFE for Superior Chemical & Thermal Sealing

- How do expanded PTFE gaskets handle surface irregularities? Achieve a Perfect Seal on Imperfect Flanges