In essence, spring-energized PTFE seals provide reliable performance where traditional elastomeric seals fail. They combine the extreme chemical inertness and low-friction properties of Polytetrafluoroethylene (PTFE) with a metal spring energizer, creating a robust seal that maintains constant pressure against the sealing surface across a vast range of temperatures, pressures, and chemical environments.

The core problem with standard seals is their tendency to fail under stress—they harden, degrade, or lose their shape. Spring-energized PTFE seals solve this by using a durable material (PTFE) for the seal jacket and an active mechanical spring to ensure a constant, reliable sealing force, no matter the conditions.

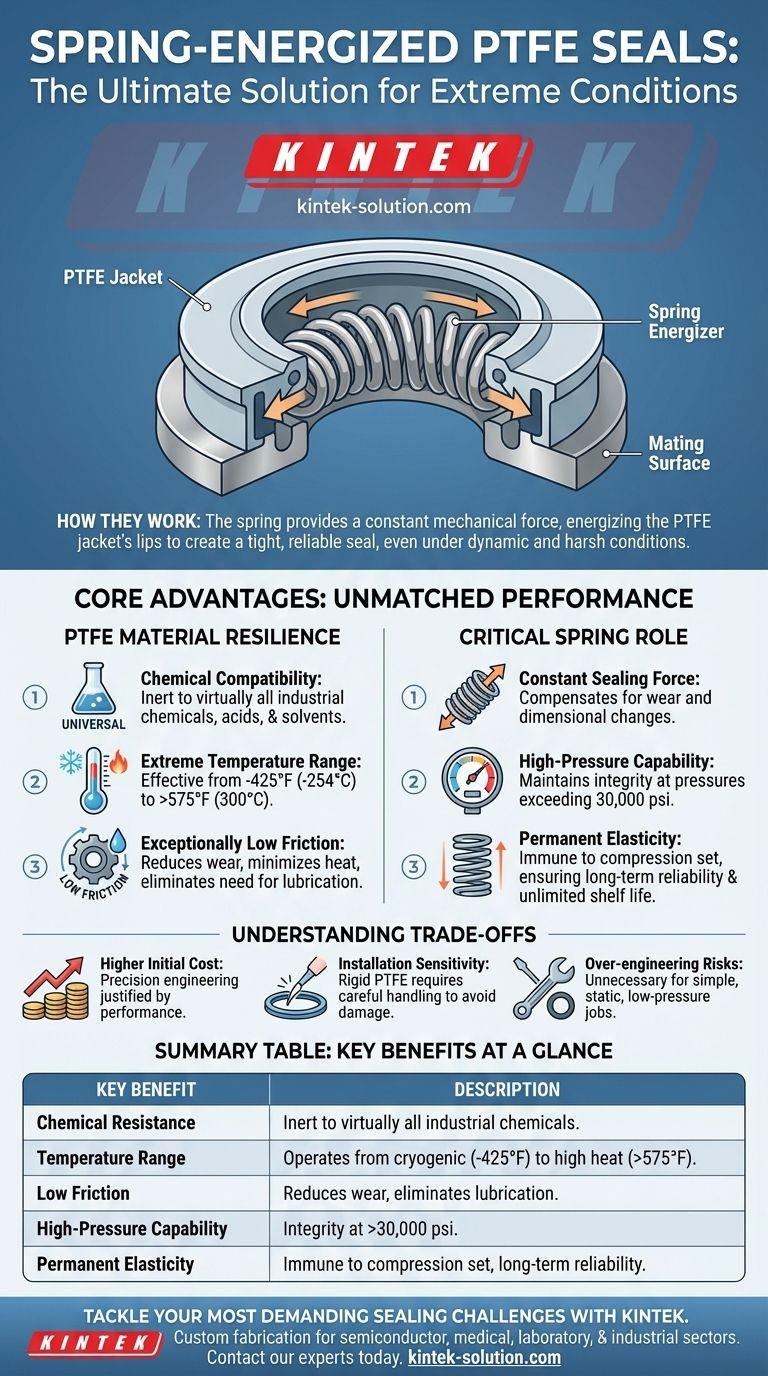

How Spring-Energized PTFE Seals Function

A spring-energized seal consists of two primary components: a precision-machined PTFE jacket and an internal energizing spring.

The PTFE Jacket

The jacket is the main body of the seal and is what makes contact with the hardware. It is machined from various grades of PTFE, a material known for its unique properties. The shape of the jacket's lip is critical for sealing performance.

The Spring Energizer

The spring fits inside the PTFE jacket. Its function is to provide a constant, resilient mechanical force that pushes the lips of the jacket outward, creating a tight seal against the mating surfaces. This spring action is what makes the seal so effective in dynamic situations.

Core Advantages of the Design

The unique combination of a PTFE jacket and a spring energizer delivers performance benefits that are impossible to achieve with a single-material seal.

Unmatched Material Resilience

The PTFE material itself offers a powerful baseline of resistance.

- Universal Chemical Compatibility: PTFE is virtually inert to all industrial chemicals, including aggressive acids, bases, and solvents. This makes it ideal for pharmaceutical, chemical processing, and semiconductor applications.

- Extreme Temperature Range: These seals operate effectively in both cryogenic conditions down to -425°F (-254°C) and high-heat environments exceeding 575°F (300°C).

- Exceptionally Low Friction: PTFE has one of the lowest coefficients of friction of any solid material. This reduces wear, minimizes heat generation in high-speed applications, and eliminates the need for lubrication.

The Critical Role of the Spring

The spring elevates the performance of the PTFE, compensating for its natural limitations.

- Constant Sealing Force: The spring ensures consistent pressure even as the seal jacket wears down over time. It also adapts to any dimensional changes in the hardware caused by thermal expansion or contraction.

- High-Pressure Capability: In high-pressure applications, the spring provides the necessary force to prevent the seal from being pushed away from the sealing surface, maintaining integrity at pressures over 30,000 psi.

- Permanent Elasticity: Unlike rubber seals that suffer from compression set (a permanent deformation after being compressed), the spring provides permanent elasticity. This guarantees long-term reliability and an unlimited shelf life, as the seal will not age or become brittle.

Understanding the Trade-offs

While highly effective, these seals are a specialized solution, not a universal replacement for all other seal types. Understanding their limitations is key to using them correctly.

Higher Initial Cost

Spring-energized PTFE seals are precision-engineered components and are significantly more expensive than standard O-rings or other elastomeric seals. Their cost is justified by performance and longevity in applications where other seals would fail quickly.

Installation Sensitivity

The PTFE jacket is a relatively rigid plastic. It can be damaged (scratched or nicked) during installation if proper care and tools are not used. A damaged seal lip will compromise performance immediately.

Over-engineering for Simple Jobs

Using a spring-energized PTFE seal in a simple, static, low-pressure, and non-aggressive environment is often unnecessary. A standard, more cost-effective elastomeric seal is typically sufficient for such applications.

Making the Right Choice for Your Application

Selecting the right seal requires matching its capabilities to your primary engineering challenge.

- If your primary focus is aggressive chemicals or extreme temperatures: The near-universal chemical inertness and wide temperature range of the PTFE material make this seal the default choice.

- If your primary focus is high pressure or high-speed dynamics: The spring-energized design provides the constant force and low-friction surface needed to ensure seal integrity and prevent premature wear.

- If your primary focus is long-term reliability and minimal maintenance: The immunity to compression set, aging, and embrittlement makes it the ideal solution for critical systems or hardware that is difficult to service.

Ultimately, view the spring-energized PTFE seal as a problem-solving tool for your most demanding sealing applications.

Summary Table:

| Key Benefit | Description |

|---|---|

| Chemical Resistance | Inert to virtually all industrial chemicals, acids, and solvents. |

| Temperature Range | Operates from cryogenic (-425°F) to high heat (over 575°F). |

| Low Friction | Reduces wear and eliminates the need for lubrication. |

| High-Pressure Capability | Maintains integrity at pressures exceeding 30,000 psi. |

| Permanent Elasticity | Immune to compression set, ensuring long-term reliability. |

Tackle your most demanding sealing challenges with KINTEK.

If your application involves extreme temperatures, aggressive chemicals, high pressure, or requires long-term reliability with minimal maintenance, our precision-manufactured spring-energized PTFE seals are the solution. We specialize in custom fabrication for the semiconductor, medical, laboratory, and industrial sectors, delivering high-performance components from prototypes to high-volume orders.

Contact our experts today to discuss your specific requirements and get a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability