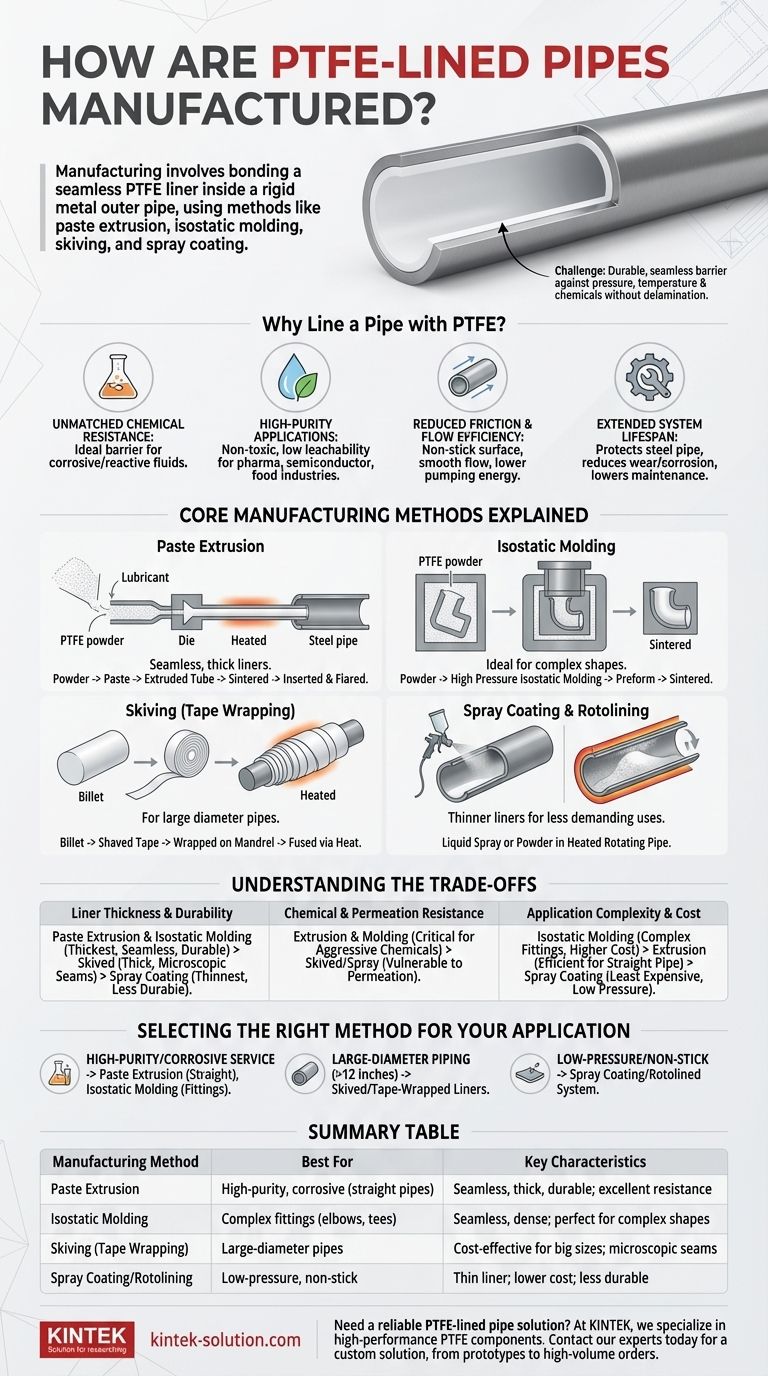

At its core, manufacturing a PTFE-lined pipe involves bonding a seamless or near-seamless Polytetrafluoroethylene (PTFE) liner inside a rigid outer pipe, typically made of carbon steel or stainless steel. The primary methods to achieve this are paste extrusion, isostatic molding, skiving (tape wrapping), and spray coating, each chosen based on the pipe's intended application and performance requirements.

The central challenge in manufacturing is not just applying the PTFE, but creating a durable, seamless barrier that can withstand pressure, temperature, and corrosive chemicals without delaminating from the outer pipe structure.

Why Line a Pipe with PTFE?

Before examining the manufacturing methods, it's essential to understand the goal. A PTFE-lined pipe is a composite system designed to combine the structural strength of metal with the unique properties of PTFE.

### Unmatched Chemical Resistance

PTFE is one of the most chemically inert materials known. This makes it an ideal barrier for transporting highly corrosive or reactive fluids that would quickly degrade standard metal pipes.

### High-Purity Applications

The material is non-toxic and has extremely low leachability. This ensures that the fluid being transported remains uncontaminated, which is critical in the pharmaceutical, semiconductor, and food processing industries.

### Reduced Friction and Flow Efficiency

PTFE has an exceptionally low coefficient of friction, often compared to wet ice on wet ice. This non-stick surface prevents buildup, ensures smooth fluid flow, and can reduce the energy required for pumping.

### Extended System Lifespan

By protecting the structural steel pipe from the internal process fluid, the PTFE lining dramatically reduces wear and corrosion. This extends the entire piping system's operational life and lowers long-term maintenance costs.

Core Manufacturing Methods Explained

The choice of manufacturing method dictates the liner's thickness, durability, and suitability for specific pressures and temperatures.

### Paste Extrusion

Paste extrusion is one of the most common methods for creating high-quality, seamless liners. A fine PTFE powder is mixed with a lubricant to form a paste, which is then forced through a die to create a continuous, thin-walled tube.

This tube is then heated (sintered) to remove the lubricant and fuse the PTFE particles into a solid, seamless liner. The finished liner is inserted into the steel pipe and "flared" over the flanges at each end to lock it in place.

### Isostatic Molding

This method is ideal for creating liners for complex shapes like elbows, tees, and instrument connections. PTFE powder is placed into a mold that is then subjected to high pressure from all directions (isostatically).

The pressure compacts the powder into a solid "preform" shape. Like with extrusion, this preform is then sintered at high temperatures to create a dense, robust, and seamless part that perfectly fits the complex component.

### Skiving (Tape Wrapping)

Skiving involves shaving a thin, continuous tape from a large, solid billet of molded PTFE. This tape is then wrapped around a mandrel, often with multiple layers, and heated to fuse the layers together into a solid tube.

This method is particularly effective for producing liners for very large diameter pipes where extrusion may not be practical.

### Spray Coating and Rotolining

For less demanding applications, a liquid dispersion of PTFE can be sprayed onto the pipe's interior surface in multiple layers. A similar process, rotolining, uses PTFE powder inside a heated, rotating pipe, allowing the powder to melt and coat the interior wall.

These methods typically produce thinner liners and are best suited for applications where the primary goal is creating a non-stick surface rather than providing heavy-duty corrosion protection.

Understanding the Trade-offs

No single manufacturing method is universally superior. The right choice depends on a balance of performance, geometry, and cost.

### Liner Thickness and Durability

Paste extrusion and isostatic molding produce the thickest and most durable liners. Their seamless, dense structure provides the highest resistance to physical wear and permeation by aggressive chemicals.

Skived liners can also be thick but contain microscopic seams from the wrapping process. Spray coating produces the thinnest liner, making it more susceptible to scratches or wear.

### Chemical and Permeation Resistance

For highly aggressive or diffusive chemicals (like chlorine or bromine), a thick, seamless liner from extrusion or molding is critical. Thinner or seamed liners are more vulnerable to chemical permeation, which can lead to liner collapse or damage to the outer steel pipe.

### Application Complexity and Cost

Isostatic molding is the go-to method for complex fittings, though it carries higher tooling costs. Extrusion is highly efficient for straight pipe sections.

Spray coating is generally the least expensive option but is limited to low-pressure, low-temperature, and less corrosive services.

Selecting the Right Method for Your Application

Your final decision should be driven entirely by the demands of your specific process.

- If your primary focus is high-purity or highly corrosive service: You need the robust, seamless barrier provided by paste extrusion for straight pipes and isostatic molding for fittings.

- If your primary focus is large-diameter piping (over 12 inches): Skived and tape-wrapped liners are often the most practical and cost-effective solution.

- If your primary focus is low-pressure, non-stick performance: A spray-coated or rotolined system can provide the necessary surface properties at a lower cost.

Ultimately, understanding how these pipes are made empowers you to select a system that ensures safety, reliability, and long-term performance.

Summary Table:

| Manufacturing Method | Best For | Key Characteristics |

|---|---|---|

| Paste Extrusion | High-purity, corrosive service (straight pipes) | Seamless, thick, durable liner; excellent chemical resistance |

| Isostatic Molding | Complex fittings (elbows, tees) | Seamless, dense liner; perfect for complex shapes |

| Skiving (Tape Wrapping) | Large-diameter pipes | Cost-effective for big sizes; microscopic seams from wrapping |

| Spray Coating/Rotolining | Low-pressure, non-stick applications | Thin liner; lower cost; less durable for harsh chemicals |

Need a reliable PTFE-lined pipe solution for your critical application?

At KINTEK, we specialize in manufacturing high-performance PTFE components, including custom-lined pipes, seals, and labware. Whether you're in the semiconductor, medical, laboratory, or industrial sector, we understand the importance of precision, chemical resistance, and system longevity.

We can help you select the ideal manufacturing method—from paste extrusion for seamless barriers to isostatic molding for complex fittings—ensuring your system meets the highest standards for purity and corrosion resistance.

Let's discuss your project requirements. Contact our experts today for a custom solution, from prototypes to high-volume orders.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- How have PTFE coatings transformed the food processing industry? Boosting Efficiency, Safety & Profitability

- How do PTFE bushes reduce friction between moving parts? Achieve Maintenance-Free, Low-Friction Motion

- What are the key characteristics of PTFE ram extrusion? Efficient Production of Long PTFE Rods & Tubes

- What industries commonly use PTFE valves and components? Essential for Chemical & Purity Applications

- What are the common challenges in PTFE machining related to tool wear? How to Extend Tool Life and Cut Costs

- Why is PTFE used for gaskets? Superior Sealing for Harsh Chemical & Temperature Environments

- What are the key advantages of using PTFE envelope gaskets? Superior Sealing for Aggressive Chemical & High-Pressure Applications

- How are PTFE gaskets applied in the automotive industry? Ensure Reliable Seals in Harsh Environments