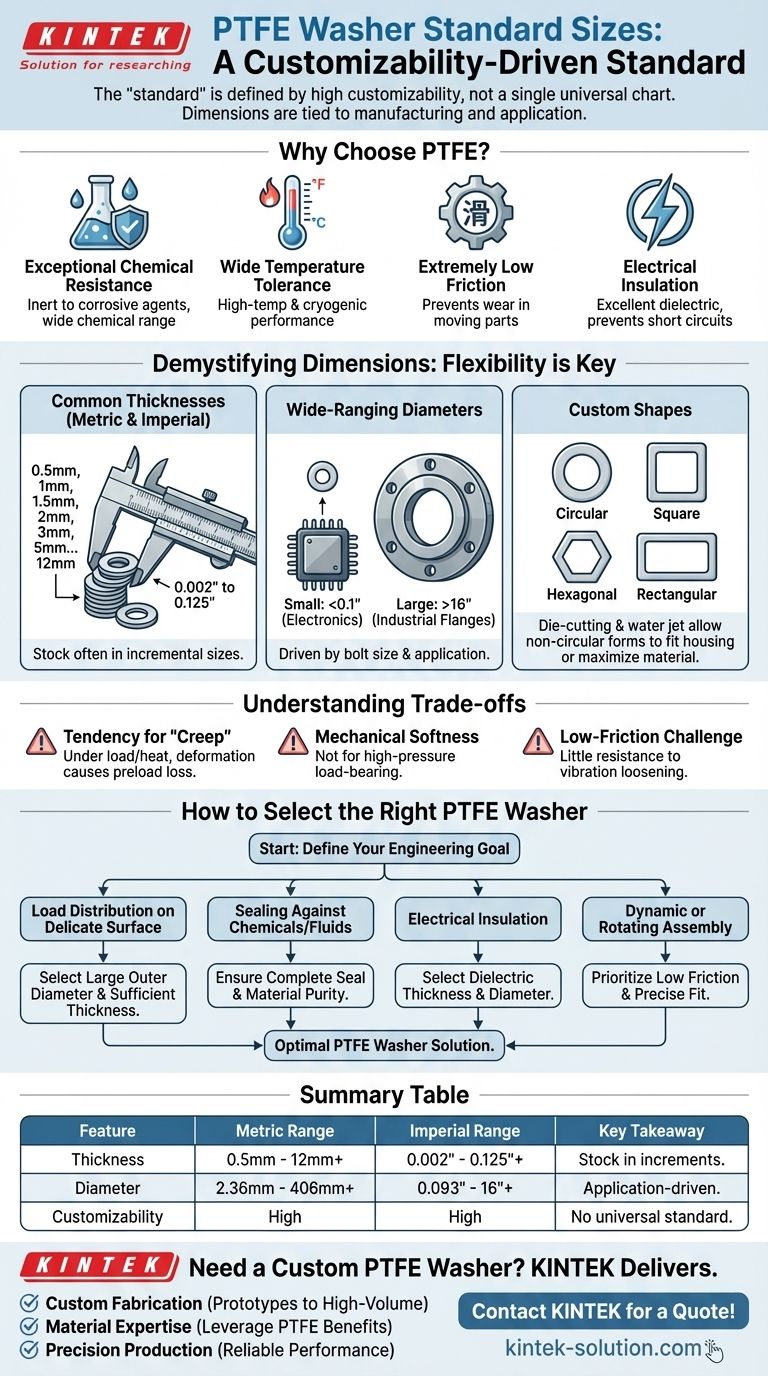

To answer your question directly, PTFE washers are available in a vast range of sizes, with common thicknesses including 0.5mm, 1mm, 1.5mm, 2mm, 3mm, 5mm, and up to 12mm. Diameters can range from as small as 0.093 inches to as large as 16 inches, demonstrating that "standard" is less about a single universal chart and more about what is commonly manufactured for specific industries.

The key isn't finding a universal "standard size" for PTFE washers, but understanding that their dimensions are fundamentally tied to their manufacturing process and intended application. The true standard is their high degree of customizability.

The Role of a PTFE Washer

Before diving into dimensions, it's crucial to understand why PTFE (Polytetrafluoroethylene) is chosen. Its properties dictate its use and, consequently, its required size and shape.

### Exceptional Chemical Resistance

PTFE is nearly inert, making it ideal for washers used in highly corrosive environments, such as chemical processing or medical applications. It resists damage from aggressive cleaning agents and a wide array of industrial chemicals.

### Wide Temperature Tolerance

These washers maintain their integrity and performance in both high-temperature and cryogenic applications, a range few other polymers can match.

### Extremely Low Friction

Known for its "slipperiness," PTFE has one of the lowest coefficients of friction of any solid material. This makes it perfect for assemblies with moving or rotating parts where you need to reduce wear and prevent seizing.

### Electrical Insulation

PTFE is an excellent electrical insulator (a dielectric). This property makes it invaluable for mounting components in electronics, preventing short circuits while resisting heat.

Demystifying PTFE Washer Dimensions

The concept of a "standard" size is fluid because PTFE washers are typically cut from large sheets. This manufacturing flexibility is their greatest strength.

### Common Thicknesses

While custom thicknesses are always possible, manufacturers often produce stock in incremental metric sizes. Common options you will find readily available include 0.5mm, 1mm, 1.5mm, 2mm, 2.5mm, 3mm, 4mm, 5mm, 6mm, 8mm, 10mm, and 12mm. Imperial thicknesses often range from 0.002 to 0.125 inches.

### Wide-Ranging Diameters

Diameters are even more varied, driven entirely by the bolt sizes and surface areas of specific applications. It's common to see ranges from under 0.1 inches (for electronics) to over 16 inches (for industrial flanges).

### Custom Shapes and Forms

Because they are cut using methods like die-cutting or water jet cutting, PTFE washers are not limited to a circular shape. Square, hexagonal, or rectangular washers can be produced to fit specific housing constraints or to maximize material usage from a sheet, reducing waste.

Understanding the Trade-offs

While PTFE is a remarkable material, it's not without its limitations. Understanding these is critical for proper selection.

### Tendency for "Creep"

Under a constant, heavy load (especially at elevated temperatures), pure PTFE can slowly deform over time. This phenomenon, known as creep or cold flow, can cause a bolted joint to lose its preload. This is the most significant trade-off to consider in structural applications.

### Mechanical Softness

PTFE is a relatively soft material. While this helps it conform to surfaces and create a good seal, it also means it's not suitable for extremely high-pressure load-bearing applications where a hardened steel washer would be required.

### The Low-Friction Challenge

The same property that makes PTFE excellent for rotating parts can be a minor drawback in static joints. The material's slipperiness means it provides very little friction to help prevent a nut or bolt from vibrating loose.

How to Select the Right PTFE Washer

Choosing the correct washer is a matter of matching the dimensions and material properties to your specific engineering goal.

- If your primary focus is load distribution on a delicate surface: Choose a washer with an outer diameter large enough to spread the force, and a thickness sufficient to prevent the bolt head from deforming it.

- If your primary focus is sealing against chemicals or fluids: Ensure the washer's inner and outer diameters create a complete seal around the fastener and against the mating surface. Material purity (e.g., food-grade) may also be a critical factor.

- If your primary focus is electrical insulation: Select a thickness that provides the necessary dielectric separation for your voltage requirements and a diameter that prevents any contact between conductive components.

- If your primary focus is a dynamic or rotating assembly: Prioritize the low-friction properties of pure PTFE and select a size that fits the shaft or bolt precisely to minimize play and wear.

Ultimately, the right PTFE washer is the one whose dimensions and unique material characteristics solve your specific engineering challenge.

Summary Table:

| Common PTFE Washer Sizes | Thickness (Metric) | Thickness (Imperial) | Diameter Range |

|---|---|---|---|

| Typical Thickness | 0.5mm, 1mm, 2mm, 3mm, 5mm, up to 12mm | 0.002" to 0.125" | Varies by application |

| Typical Diameter | - | - | 0.093" (2.36mm) to 16" (406mm) and beyond |

| Key Takeaway | Sizes are highly customizable; stock is available in common increments. | Dimensions are application-driven, not governed by a single universal standard. |

Need a PTFE Washer in a Specific Size?

KINTEK specializes in manufacturing high-precision PTFE components, including washers, seals, liners, and custom labware. Whether your application is in the semiconductor, medical, laboratory, or industrial sector, we provide the perfect fit.

We deliver:

- Custom Fabrication: From prototypes to high-volume orders, we create washers in the exact dimensions, thickness, and shape you need.

- Material Expertise: Leverage the full benefits of PTFE—chemical resistance, temperature tolerance, and low friction—for your critical applications.

- Precision Production: Ensure reliable performance and a perfect seal every time.

Let us solve your specific engineering challenge. Contact KINTEK today for a quote on custom PTFE washers!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions