In the construction industry, glass-filled Polytetrafluoroethylene (PTFE) serves a critical and highly specialized role. It is most frequently engineered into high-performance structural bearing pads, which act as a durable, low-friction interface between materials like steel and concrete. Its unique properties also make it a superior choice for robust electrical insulation and corrosion-resistant components in piping systems.

The core value of glass-filled PTFE in construction lies in its unique fusion of properties: the extreme chemical inertness and weather resistance of PTFE combined with the enhanced compressive strength, stiffness, and wear resistance imparted by glass fibers.

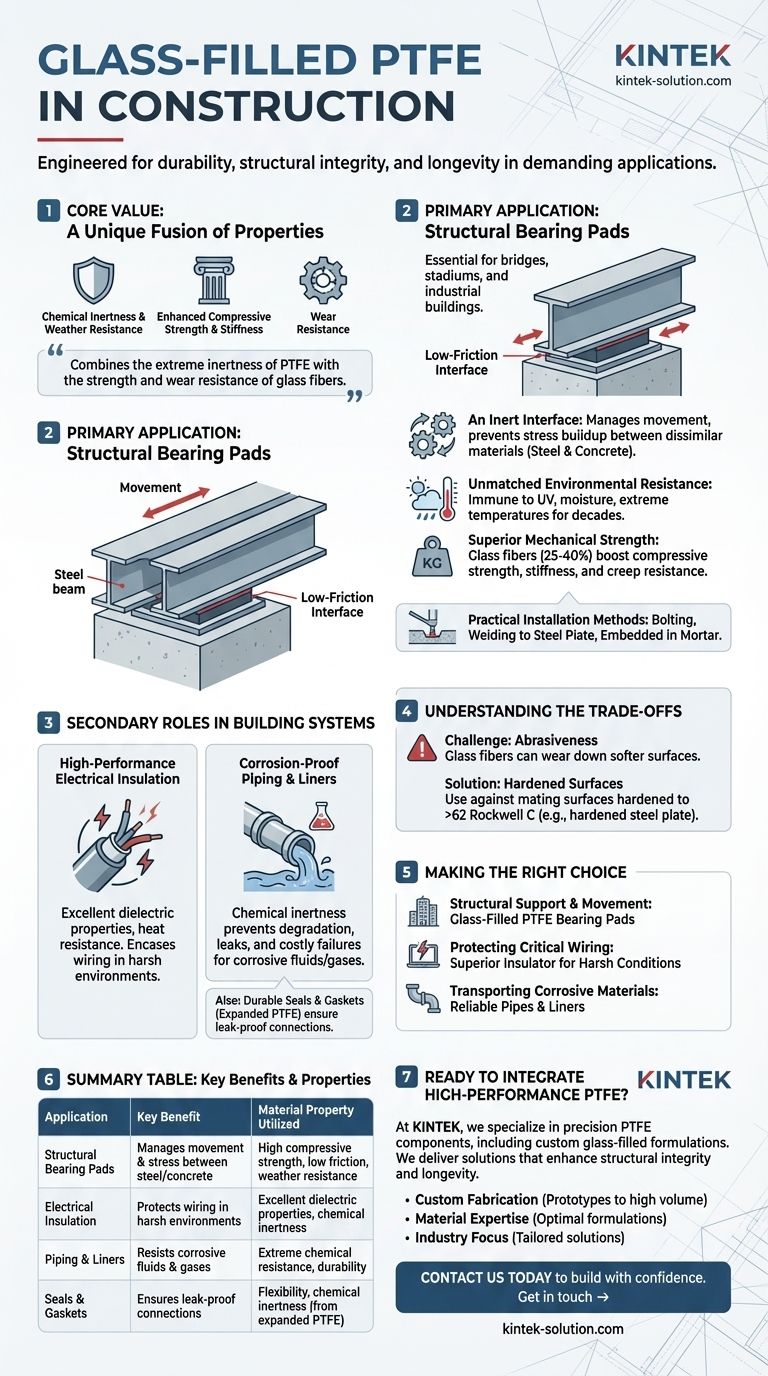

The Primary Application: Structural Bearing Pads

The most significant use of glass-filled PTFE in construction is for creating slide bearings and bearing pads. These components are essential for the integrity and longevity of large structures like bridges, stadiums, and heavy industrial buildings.

An Inert Interface for Dissimilar Materials

Structures are not static; they expand, contract, and settle. Glass-filled PTFE pads provide a low-friction surface that allows for this movement between massive components, such as a steel beam resting on a concrete pier. This prevents the buildup of destructive stress.

Unmatched Environmental Resistance

Placed in exposed locations, these bearing pads must withstand decades of abuse. Glass-filled PTFE is virtually immune to all forms of weather-related degradation, including UV radiation, moisture, and extreme temperature cycles, ensuring reliable performance over the structure's lifetime.

Superior Mechanical Strength

Standard PTFE is too soft for high-load applications. The addition of glass fibers, typically making up 25% to 40% of the compound, dramatically increases the material's compressive strength, stiffness, and resistance to "creep" (the tendency to deform slowly under a constant load).

Practical Installation Methods

These pads are designed for real-world construction sites. They can be integrated into a structure through various methods, including bolting, welding to a steel plate, or being embedded in mortar, making them a versatile engineering solution.

Secondary Roles in Building Systems

While bearing pads are the primary application, the properties of glass-filled PTFE make it valuable for other critical systems within a building or infrastructure project.

High-Performance Electrical Insulation

PTFE's excellent dielectric properties and high-temperature resistance make it an effective insulator. It is used to encase and protect electrical wiring, especially in environments where there is a risk of exposure to heat, water, or chemicals.

Corrosion-Proof Piping and Liners

For systems transporting corrosive fluids or gases, PTFE is an ideal material for pipes, hoses, and liners. Its chemical inertness ensures that the transport system will not degrade, preventing leaks and costly failures.

Durable Seals and Gaskets

Expanded PTFE, a related material, is frequently used to seal flange joints in pipelines, fire hydrants, and hydraulic systems. This highlights the broader utility of the PTFE family in ensuring leak-proof connections in critical infrastructure.

Understanding the Trade-offs

No material is perfect. While glass-filled PTFE offers incredible benefits, its primary limitation comes from the very fibers that give it strength.

The Challenge of Abrasiveness

The glass fibers that provide strength also make the material abrasive. When used in a moving application, a glass-filled PTFE surface can wear down a softer mating surface over time.

The Need for Hardened Surfaces

Because of its abrasiveness, glass-filled PTFE should only be used against a very hard counterpart. The industry standard is a mating surface, like a steel plate or shaft, that is hardened to greater than 62 Rockwell C to prevent premature wear.

Making the Right Choice for Your Application

Selecting the right material is about matching its properties to the specific demands of the job.

- If your primary focus is structural support and movement: Glass-filled PTFE bearing pads are the definitive choice for managing heavy loads between dissimilar materials like steel and concrete.

- If your primary focus is protecting critical wiring: Its exceptional resistance to heat, moisture, and chemicals makes it a superior insulator for demanding electrical systems.

- If your primary focus is transporting corrosive materials: The material's chemical inertness makes it a reliable choice for pipes and liners, ensuring long-term system integrity.

By understanding its unique balance of strength, inertness, and environmental resistance, you can leverage glass-filled PTFE to engineer systems and structures that are truly built to last.

Summary Table:

| Application | Key Benefit | Material Property Utilized |

|---|---|---|

| Structural Bearing Pads | Manages movement & stress between steel/concrete | High compressive strength, low friction, weather resistance |

| Electrical Insulation | Protects wiring in harsh environments | Excellent dielectric properties, chemical inertness |

| Piping & Liners | Resists corrosive fluids & gases | Extreme chemical resistance, durability |

| Seals & Gaskets | Ensures leak-proof connections | Flexibility, chemical inertness (from expanded PTFE) |

Ready to integrate high-performance PTFE components into your next construction project?

At KINTEK, we specialize in manufacturing precision PTFE components, including custom glass-filled formulations for demanding applications in the construction, industrial, and specialized sectors. Whether you need durable bearing pads, corrosion-resistant liners, or custom-fabricated parts, we deliver solutions that enhance structural integrity and longevity.

We offer:

- Custom Fabrication: From prototypes to high-volume orders.

- Material Expertise: Optimal glass-filled PTFE formulations for strength and environmental resistance.

- Industry Focus: Tailored solutions for semiconductor, medical, laboratory, and industrial needs.

Contact us today to discuss your specific requirements and let us help you build with confidence. Get in touch →

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the key features of PTFE gaskets? Unlock Superior Chemical & Thermal Sealing

- What are the six main factors affecting CNC machining of PTFE parts? Master Precision Machining for High-Performance Polymers

- What are the main applications of PTFE gaskets? Sealing Solutions for Harsh Chemical & High-Temp Environments

- What are the properties of PTFE encapsulated O-rings? Superior Sealing for Harsh Environments

- How is PTFE used in the medical device industry? Enhancing Safety and Performance in Medical Devices

- What are PTFE-coated O-rings? Solve Friction & Chemical Sealing Challenges

- What are the common applications of expanded PTFE? Unlock High-Performance Sealing, Filtration & Medical Solutions

- How does the built-in spring help PTFE shaft seals adapt to varying conditions? Ensure a Reliable, Long-Lasting Seal