At its core, a PTFE gasket is defined by its extreme chemical inertness and wide temperature tolerance. Known technically as Polytetrafluoroethylene, this material offers a unique combination of properties, including near-universal chemical resistance, the ability to function from cryogenic lows to high heat, an inherently non-stick surface, and excellent purity, making it a critical sealing solution in demanding industries.

While PTFE offers near-universal chemical resistance and a vast temperature range, its primary limitation is its inherent softness. This makes it susceptible to 'creep' or cold flow under pressure, a trade-off that is critical to understand when selecting the right type of gasket for your application.

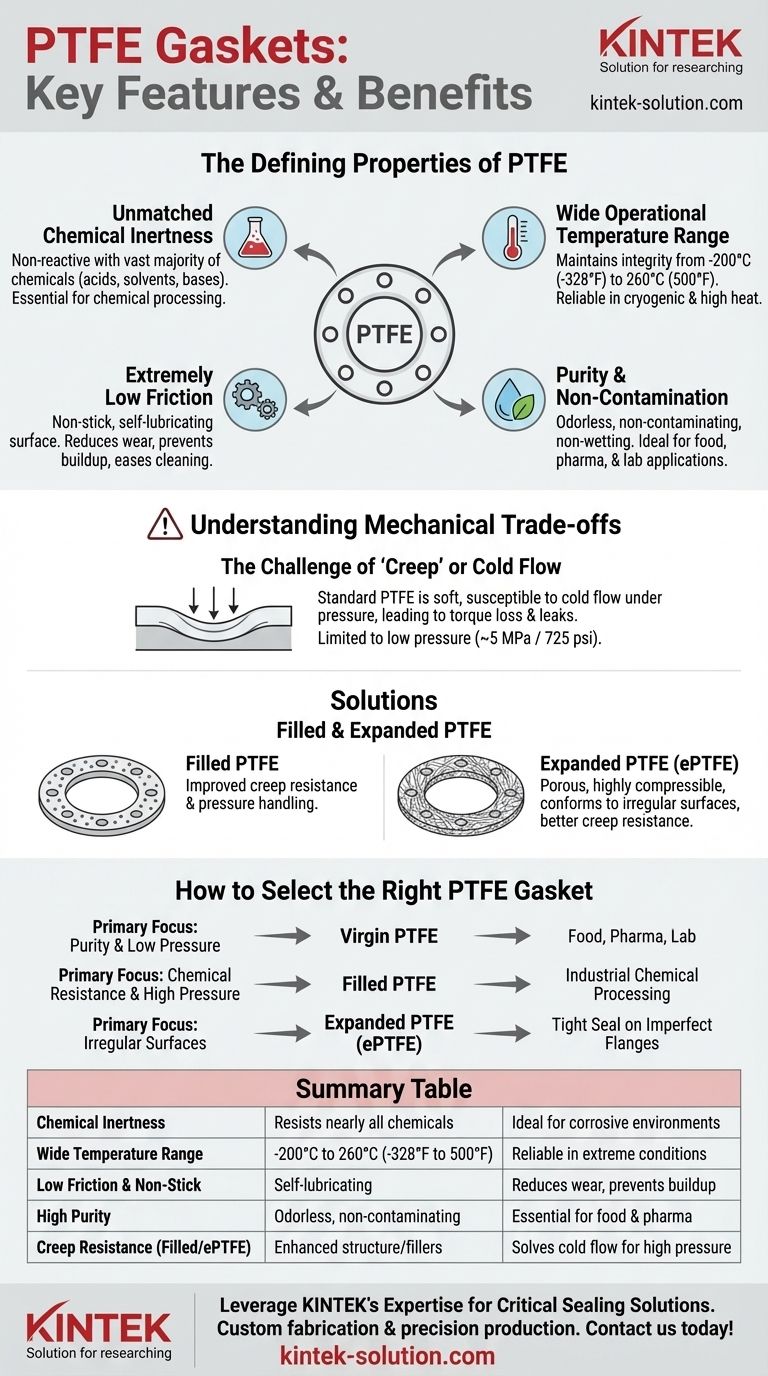

The Defining Properties of PTFE

The characteristics of PTFE make it one of the most versatile gasket materials available. These properties are intrinsic to the molecular structure of the material itself.

Unmatched Chemical Inertness

A PTFE gasket is non-reactive with the vast majority of chemicals, including aggressive acids, solvents, and bases. This makes it an essential choice for applications in chemical processing, manufacturing, and laboratories where corrosive media are common.

Wide Operational Temperature Range

PTFE maintains its integrity and sealing capability across an exceptionally broad temperature spectrum. It performs reliably in cryogenic conditions as low as -200°C (-328°F) and in heated environments up to 260°C (500°F).

Extremely Low Friction

The material has one of the lowest coefficients of friction of any solid, giving it a non-stick, self-lubricating surface. This reduces wear and tear on components, prevents material buildup, and makes disassembly and cleaning significantly easier.

Purity and Non-Contamination

Virgin PTFE is inherently odorless, non-contaminating, and non-wetting. Because it won't impart taste or color, it is a clean sealing solution widely approved and used in the food, beverage, and pharmaceutical industries.

Excellent Insulation Capabilities

In its virgin form, PTFE serves as a superior electrical and thermal insulator. This property is valuable in applications where you need to prevent electrical conductivity or reduce thermal transfer between sealed components.

Understanding the Mechanical Trade-offs

Despite its exceptional chemical and thermal properties, the primary challenge with standard PTFE is its mechanical performance under load.

The Challenge of 'Creep' or Cold Flow

Standard, or "virgin," PTFE is a relatively soft material. When subjected to sustained compressive force (like the bolt load on a flange), it can slowly deform or "creep" out of place. This phenomenon, known as cold flow, can lead to a loss of bolt torque and, eventually, a leak.

This softness limits pure PTFE gaskets to relatively low-pressure applications, often cited at a maximum of around 5 MPa (725 psi).

The Solution: Filled and Expanded PTFE

To overcome the mechanical limitations of virgin PTFE, manufacturers have developed enhanced versions.

Filled PTFE gaskets incorporate materials like glass, carbon, or graphite into the PTFE matrix. These fillers dramatically improve the gasket's resistance to creep and increase its pressure handling capabilities without significantly compromising its chemical resistance.

Expanded PTFE (ePTFE) is created through a process that introduces a porous, fibrous structure. This material is highly compressible and conforms easily to irregular or damaged flange surfaces while exhibiting much better creep resistance than virgin PTFE.

How to Select the Right PTFE Gasket

Your optimal choice depends entirely on the specific demands of your sealing application. Focusing on the primary challenge you need to solve will guide you to the correct material.

- If your primary focus is purity and moderate conditions: Virgin PTFE is the ideal choice for food, pharmaceutical, or laboratory applications where contamination is the main concern and pressures are low.

- If your primary focus is chemical resistance under high pressure: A filled PTFE gasket (e.g., glass-filled or carbon-filled) provides the necessary resistance to creep and is better suited for demanding industrial chemical processing.

- If your primary focus is sealing irregular or damaged surfaces: Expanded PTFE (ePTFE) offers excellent compressibility and conformity, creating a tight seal even on less-than-perfect flange faces.

By matching the specific type of PTFE to your application's mechanical and chemical stresses, you can fully leverage the material's exceptional sealing capabilities.

Summary Table:

| Key Feature | Description | Benefit |

|---|---|---|

| Chemical Inertness | Resists nearly all chemicals, including acids and solvents. | Ideal for corrosive environments in chemical processing and labs. |

| Wide Temperature Range | Performs from -200°C to 260°C (-328°F to 500°F). | Reliable sealing in cryogenic and high-heat applications. |

| Low Friction & Non-Stick | Self-lubricating surface with a very low coefficient of friction. | Reduces wear, prevents material buildup, and eases cleaning. |

| High Purity | Odorless, non-contaminating, and non-wetting. | Essential for food, pharmaceutical, and beverage industries. |

| Creep Resistance (Filled/ePTFE) | Enhanced with fillers (glass, carbon) or expanded structure. | Solves cold flow, enabling use in higher-pressure applications. |

Leverage KINTEK's Expertise for Your Critical Sealing Solutions

Do you need a reliable PTFE gasket that can withstand your application's specific chemical, thermal, and pressure demands? The team at KINTEK specializes in manufacturing high-performance PTFE components—including seals, gaskets, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors.

We prioritize precision production and offer custom fabrication from prototypes to high-volume orders, ensuring you get the exact solution for your unique challenges.

Contact us today to discuss your project and receive a quote: Get in Touch

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech