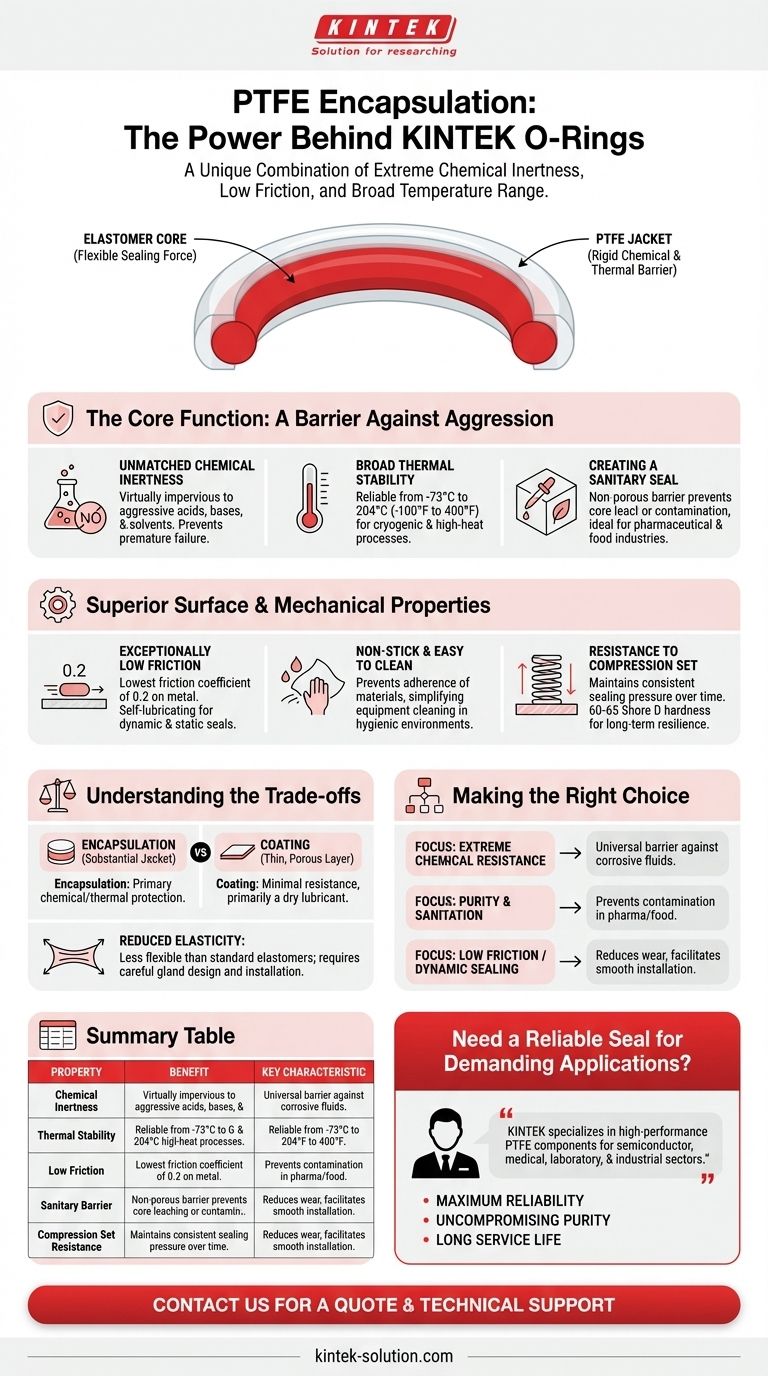

In essence, PTFE encapsulation gives an O-ring a unique combination of extreme chemical inertness, a very low-friction surface, and a wide operational temperature range. It effectively combines the sealing force of a flexible inner elastomer core with the resilience of a rigid, high-performance plastic jacket.

The central purpose of a PTFE encapsulated O-ring is to create a robust seal that can survive in aggressive chemical and thermal environments where standard elastomers would quickly fail, while also providing a clean, non-stick, low-friction surface.

The Core Function: A Barrier Against Aggression

The primary reason to use a PTFE encapsulated O-ring is to protect the seal's integrity from harsh external conditions. This is achieved through several key properties.

Unmatched Chemical Inertness

The PTFE (Polytetrafluoroethylene) jacket is virtually impervious to chemical attack. It is highly resistant to almost all industrial chemicals, including aggressive acids, bases, and solvents. This prevents the premature seal failure that is common when standard elastomers are exposed to corrosive fluids or gases.

Broad Thermal Stability

These seals are engineered to perform reliably across a very wide temperature spectrum. They maintain their properties in conditions ranging from -73°C to 204°C (-100°F to 400°F), making them suitable for both cryogenic and high-heat processes.

Creating a Sanitary Seal

The seamless PTFE encapsulation acts as a non-porous barrier between the process fluid and the inner elastomer core. This is critical in sanitary applications, as it prevents the core material from leaching or contaminating the fluid, ensuring product purity in industries like pharmaceuticals and food processing.

Superior Surface & Mechanical Properties

Beyond its defensive capabilities, the PTFE jacket provides distinct mechanical advantages that enhance performance and usability.

Exceptionally Low Friction

PTFE has one of the lowest coefficients of friction of any solid material, measured at 0.2 on metal. This creates a slippery, self-lubricating surface that is ideal for dynamic applications with moving parts or for static seals that require easy, damage-free installation.

Non-Stick and Easy to Clean

The low-friction surface is also inherently non-stick. This property simplifies the cleaning of equipment and prevents process materials from adhering to the O-ring, which is a significant advantage in hygienic environments.

Resistance to Compression Set

A low compression set means the O-ring is better at returning to its original shape after being compressed. The firm PTFE jacket (60-65 Shore D hardness) contributes to this resilience, ensuring the seal maintains consistent pressure over time for long-term, reliable performance.

Understanding the Trade-offs

While powerful, this design has specific characteristics that differ from standard elastomer O-rings. It's crucial to distinguish between a true encapsulation and a simple coating.

Encapsulation vs. Coating

A PTFE encapsulation is a substantial, seamless jacket that provides the primary chemical and thermal protection. In contrast, a PTFE coating is an extremely thin, porous layer that primarily serves as a dry lubricant for installation or as a means of color identification. A coating will wear off easily and offers minimal chemical resistance.

Reduced Elasticity

The rigid nature of the PTFE jacket means these O-rings are significantly less flexible than their standard elastomer counterparts. They have very little stretch, which must be accounted for during gland design and installation to avoid damaging the seal.

Making the Right Choice for Your Application

Selecting an O-ring requires matching its properties to the demands of your system.

- If your primary focus is extreme chemical resistance: The PTFE encapsulation provides a nearly universal barrier against corrosive fluids and gases, preventing seal degradation and system downtime.

- If your primary focus is purity and sanitation: The seamless jacket prevents the inner core from contaminating the process medium, making it ideal for pharmaceutical or food-grade applications.

- If your primary focus is low-friction or dynamic sealing: The self-lubricating, non-stick surface reduces wear in moving applications and facilitates smooth, damage-free installation.

Ultimately, choosing a PTFE encapsulated O-ring is a strategic decision for ensuring maximum reliability and longevity in your most demanding sealing environments.

Summary Table:

| Property | Benefit | Key Characteristic |

|---|---|---|

| Chemical Inertness | Resists aggressive acids, bases, and solvents | Prevents premature seal failure |

| Thermal Stability | Performs reliably in extreme temperatures | -73°C to 204°C (-100°F to 400°F) range |

| Low Friction | Self-lubricating for dynamic applications | Coefficient of friction of 0.2 on metal |

| Sanitary Barrier | Non-porous, prevents contamination | Ideal for pharmaceutical and food processing |

| Compression Set Resistance | Maintains consistent sealing pressure | 60-65 Shore D hardness for long-term performance |

Need a Reliable Seal for Your Most Demanding Applications?

PTFE encapsulated O-rings are engineered to solve sealing challenges in aggressive chemical, high-temperature, and ultra-pure environments. KINTEK specializes in the precision manufacturing of high-performance PTFE components, including custom O-rings, for the semiconductor, medical, laboratory, and industrial sectors.

We understand that a failed seal can mean costly downtime and compromised product integrity. Our expertise ensures you get a component that delivers:

- Maximum Reliability: Withstand corrosive fluids and extreme temperatures.

- Uncompromising Purity: Protect your process from contamination.

- Long Service Life: Reduce maintenance and replacement costs.

Whether you need a prototype for a new design or high-volume production, KINTEK provides custom fabrication to meet your exact specifications.

Contact us today to discuss your sealing requirements and let our experts help you find the perfect solution.

Get a Quote & Technical Support

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments