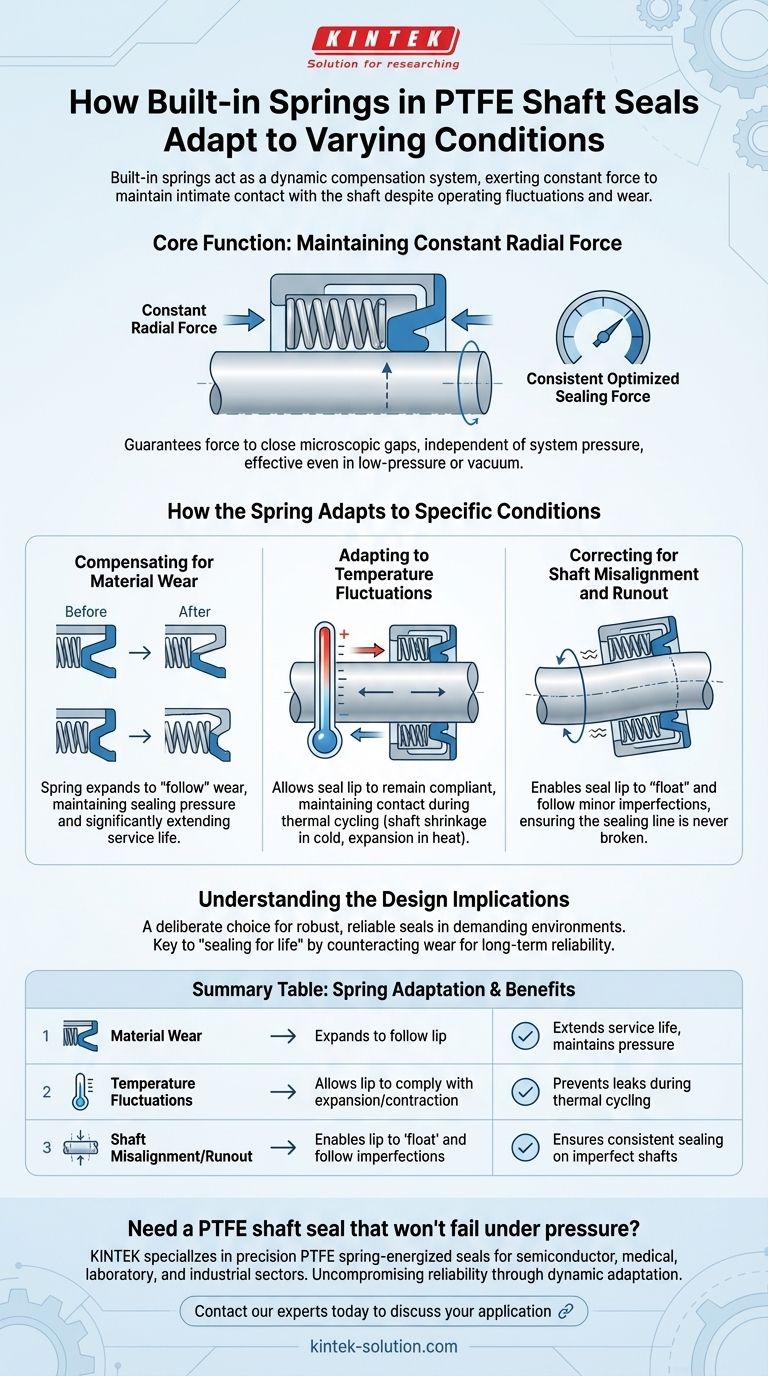

At its core, the built-in spring in a PTFE shaft seal acts as a dynamic compensation system. It exerts a constant, live force on the seal lip, ensuring it remains in intimate contact with the shaft even as operating conditions fluctuate or as the seal material naturally wears over its service life.

The spring transforms a static sealing element into a dynamic one. Its primary function is to compensate for the inevitable realities of machine operation—wear, temperature changes, and minor imperfections—to ensure a reliable seal from installation to replacement.

The Core Function: Maintaining Constant Radial Force

The effectiveness of any shaft seal depends entirely on maintaining a consistent, optimized sealing force against the rotating shaft. The spring is the mechanism that guarantees this force.

Why Sealing Force is Critical

A seal must exert enough pressure to close the microscopic gaps between the seal lip and the shaft, preventing fluid or gas from escaping.

However, too much force can accelerate wear and increase friction, while too little force will result in an immediate leak.

The Spring as a Force Regulator

The built-in spring, typically a cantilever or garter spring made of stainless steel, is precisely engineered to provide a constant radial force.

This force is independent of system pressure, making the seal effective even in low-pressure or vacuum situations where other seal designs might fail.

How the Spring Adapts to Specific Conditions

The true value of the spring is its ability to automatically adjust to the dynamic nature of most industrial and automotive applications.

Compensating for Material Wear

As the PTFE seal lip wears down from rotational friction, its contact surface changes. The spring expands slightly to "follow" the wear.

This action maintains the necessary sealing pressure, significantly extending the effective service life of the seal and ensuring consistent performance over time.

Adapting to Temperature Fluctuations

Materials expand and contract with temperature changes. A shaft might shrink in the cold or expand with operational heat.

The spring allows the seal lip to remain compliant, maintaining its contact with the shaft surface regardless of this thermal cycling.

Correcting for Shaft Misalignment and Runout

No shaft is perfectly centered or perfectly smooth. Minor eccentricities (runout) or misalignment are common in real-world machinery.

The spring allows the seal lip to "float" and dynamically follow these imperfections, ensuring the sealing line is never broken.

Understanding the Design Implications

The inclusion of a spring is a deliberate engineering choice designed to create a more robust and reliable seal for demanding environments.

The Challenge of "Sealing for Life"

In many applications, seals are installed in difficult-to-access locations. The goal is to install a component that will function reliably for thousands of hours without intervention.

The spring's ability to self-adjust for wear is the key feature that makes this long-term reliability possible, directly counteracting the most common cause of seal failure.

Complementing PTFE's Natural Strengths

PTFE is an exceptional material known for its low friction and high chemical and temperature resistance.

The spring energizer complements these properties by providing the mechanical resilience that PTFE lacks on its own, creating a seal that is both durable and highly adaptive.

Making the Right Choice for Your Application

The spring-energized design directly addresses the core challenge of maintaining a reliable seal in dynamic, imperfect conditions.

- If your primary focus is maximum reliability: The spring's ability to adapt to temperature, pressure, and misalignment makes it the superior choice for critical applications.

- If your primary focus is extending service life: The spring's compensation for material wear is the single most important feature for maximizing time between maintenance cycles.

- If your primary focus is sealing in imperfect conditions: For equipment with known shaft runout or vibration, the spring provides the necessary compliance to ensure a consistent seal.

Ultimately, the spring ensures the seal performs as intended not just in a perfect lab setting, but throughout the demanding lifecycle of the machinery it protects.

Summary Table:

| Condition | How the Spring Adapts | Benefit |

|---|---|---|

| Material Wear | Expands to follow the seal lip | Extends service life, maintains pressure |

| Temperature Fluctuations | Allows lip to comply with shaft expansion/contraction | Prevents leaks during thermal cycling |

| Shaft Misalignment/Runout | Enables lip to 'float' and follow imperfections | Ensures consistent sealing on imperfect shafts |

Need a PTFE shaft seal that won't fail under pressure?

At KINTEK, we specialize in manufacturing precision PTFE components, including high-performance spring-energized seals for the semiconductor, medical, laboratory, and industrial sectors. Our seals are engineered to deliver uncompromising reliability by dynamically adapting to wear, temperature swings, and misalignment—ensuring your equipment runs longer with zero leaks.

We offer custom fabrication from prototypes to high-volume orders, tailoring the solution to your exact needs.

Contact our experts today to discuss your application and get a seal built for endurance.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- How is vertical load accommodated in PTFE sliding bearings? Design for High Load & Movement

- Why is PTFE's ease of sterilization important for medical devices? Ensuring Patient Safety and Device Integrity

- Why are Teflon sheets important for sublimation printing? Protect Your Press & Ensure Perfect Prints

- What are the general advantages of O-ring designs? Achieve Reliable, Cost-Effective Sealing

- What is a PTFE gasket? The Ultimate Seal for Extreme Chemicals and Temperatures

- What are the main advantages of expanded PTFE gaskets? Superior Sealing Reliability vs. Pure PTFE

- What are the benefits of CNC machining for PTFE parts? Achieve Precision and Performance

- How is Teflon used in bearing pads for different load requirements? Matching PTFE Type to Load