The primary benefit of CNC machining PTFE is precision. This process allows you to transform Polytetrafluoroethylene's unique material properties—such as extreme chemical resistance and low friction—into complex components with the exacting tolerances and smooth surface finishes that other manufacturing methods cannot reliably achieve.

The core advantage is control. While PTFE's softness presents unique machining challenges, a properly optimized CNC process provides unparalleled control, enabling the creation of intricate, high-performance parts that fully leverage the material's strengths.

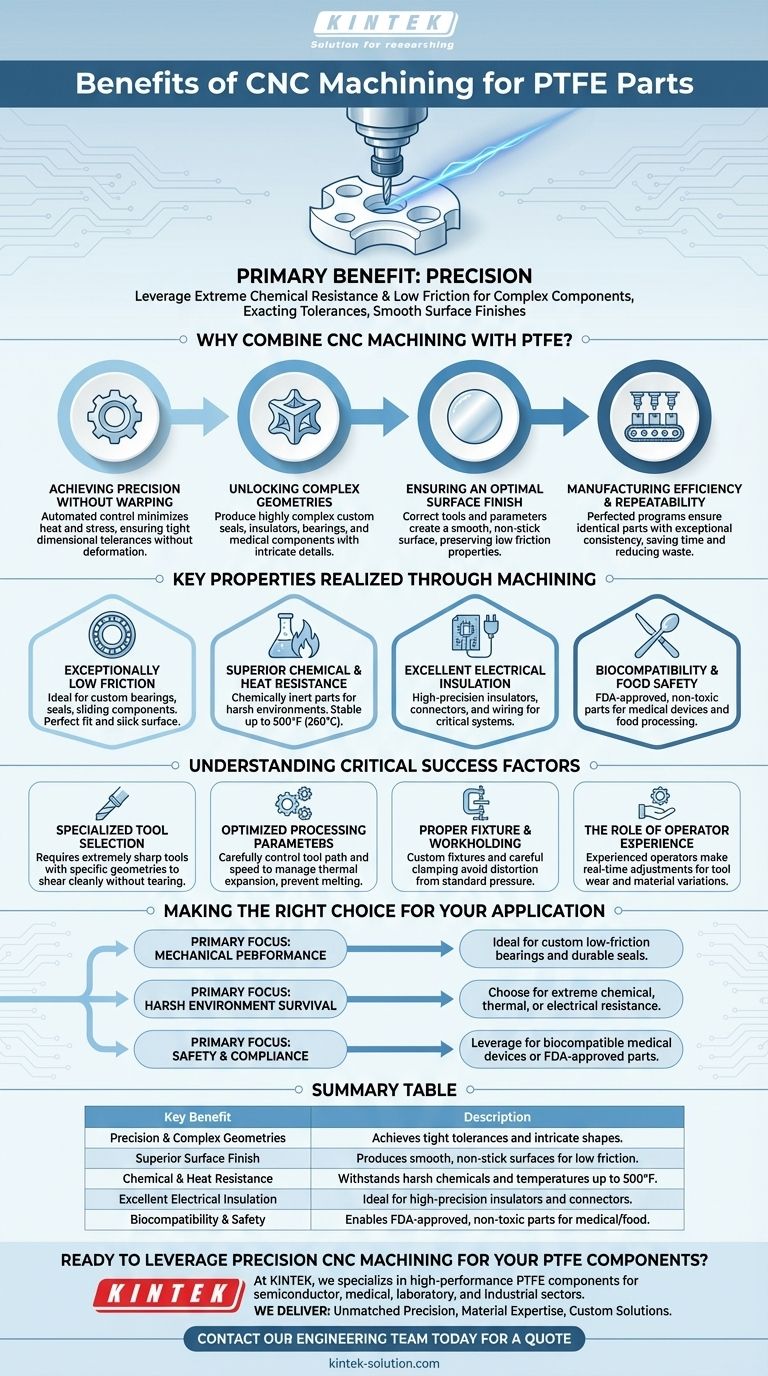

Why Combine CNC Machining with PTFE?

Choosing a manufacturing process is as critical as choosing the material itself. For PTFE, CNC machining is often the only method that can translate its impressive datasheet properties into a functional, real-world component.

Achieving Precision Without Warping

PTFE is a soft material that can be prone to deformation and stress. CNC machining, with its automated and highly controlled process, allows for precise cuts that minimize heat buildup and mechanical stress, ensuring the final part meets tight dimensional tolerances without warping.

Unlocking Complex Geometries

The versatility of CNC machines means they can produce highly complex shapes. This is essential for creating custom PTFE seals, insulators, bearings, and medical components that feature intricate details critical to their function.

Ensuring an Optimal Surface Finish

A key benefit of PTFE is its low coefficient of friction. A well-executed CNC machining process, using the correct tools and parameters, produces a smooth, non-stick surface that preserves this essential property for sliding applications.

Manufacturing Efficiency and Repeatability

Once a program is perfected, CNC machines can produce identical parts with exceptional consistency. This repeatability is crucial for both prototyping and large-scale production runs, saving time and reducing material waste.

Key Properties of PTFE Realized Through Machining

CNC machining doesn't just cut the material; it unlocks its potential for specific, demanding applications across various industries.

Exceptionally Low Friction

CNC-machined PTFE is ideal for creating custom bearings, seals, and sliding components for industries ranging from aerospace to food processing. The precision of the cut ensures a perfect fit and a slick surface.

Superior Chemical and Heat Resistance

For the chemical, oil and gas, and medical industries, components must withstand harsh environments. Machining allows for the creation of custom gaskets, linings, and fixtures that are chemically inert and stable at temperatures up to 500°F (260°C).

Excellent Electrical Insulation

The electronics and aerospace sectors rely on PTFE for its dielectric properties. CNC machining produces high-precision insulators, connectors, and wiring components that prevent electrical leakage in critical systems.

Biocompatibility and Food Safety

PTFE is non-toxic and FDA-approved, making it safe for direct contact with food and for use in medical devices. Machining allows for the production of custom, sterile surgical instruments, prosthetic devices, and food processing equipment.

Understanding the Critical Success Factors

Achieving these benefits is not automatic. The success of machining PTFE depends entirely on a process that accommodates the material's unique challenges.

Specialized Tool Selection

Standard cutting tools can push and tear soft PTFE rather than shearing it cleanly. Success requires extremely sharp tools with specific geometries (high rake and clearance angles) to achieve a clean cut and fine finish.

Optimized Processing Parameters

Incorrect speeds and feeds generate excess heat, which can cause the PTFE to melt, deform, or become gummy. Machinists must carefully control tool path and speed to manage thermal expansion and ensure accuracy.

Proper Fixture and Workholding

Because PTFE is soft and slippery, it can easily be compressed or distorted by standard clamping pressure in a CNC machine. Custom fixtures and careful clamping techniques are essential to hold the part securely without damaging it.

The Role of Operator Experience

Ultimately, the quality of a machined PTFE part relies on the skill of the machinist. An experienced operator can make real-time adjustments to the process, compensating for tool wear and material variations to maintain quality and efficiency.

Making the Right Choice for Your Application

Use this framework to determine if CNC-machined PTFE is the correct solution for your project.

- If your primary focus is mechanical performance: This combination is ideal for creating custom low-friction bearings and durable, tight-fitting seals.

- If your primary focus is harsh environment survival: Choose CNC-machined PTFE for components requiring extreme chemical, thermal, or electrical resistance.

- If your primary focus is safety and compliance: Leverage this process for biocompatible medical devices or FDA-approved parts for food and beverage equipment.

By pairing the unique advantages of PTFE with the precision of CNC machining, you can produce highly reliable components for the most demanding applications.

Summary Table:

| Key Benefit | Description |

|---|---|

| Precision & Complex Geometries | Achieves tight tolerances and intricate shapes for custom seals, insulators, and components. |

| Superior Surface Finish | Produces smooth, non-stick surfaces essential for low-friction applications. |

| Chemical & Heat Resistance | Creates parts that withstand harsh chemicals and temperatures up to 500°F (260°C). |

| Excellent Electrical Insulation | Ideal for high-precision insulators and connectors in electronics and aerospace. |

| Biocompatibility & Safety | Enables FDA-approved, non-toxic parts for medical devices and food processing equipment. |

Ready to Leverage Precision CNC Machining for Your PTFE Components?

At KINTEK, we specialize in manufacturing high-performance PTFE components for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in precision CNC machining ensures your parts meet the most demanding specifications, from complex prototypes to high-volume production runs.

We deliver the critical advantages you need:

- Unmatched Precision: Achieve the exacting tolerances and smooth finishes your application demands.

- Material Expertise: We understand how to properly machine PTFE to prevent warping and preserve its unique properties.

- Custom Solutions: From seals and liners to labware and complex insulators, we fabricate components tailored to your exact requirements.

Let's discuss how our precision PTFE machining can solve your specific challenges. Contact our engineering team today for a quote or to discuss your project.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications