In short, PTFE's ease of sterilization is critical because it allows medical devices to be made completely free of harmful microorganisms using standard, reliable methods without damaging the device itself. This directly prevents patient infections and ensures the component functions exactly as designed after the sterilization process.

The true value of PTFE in medicine isn't just its inherent properties, but its ability to maintain those properties—purity, chemical inertness, and dimensional precision—through the harsh sterilization processes required for patient safety.

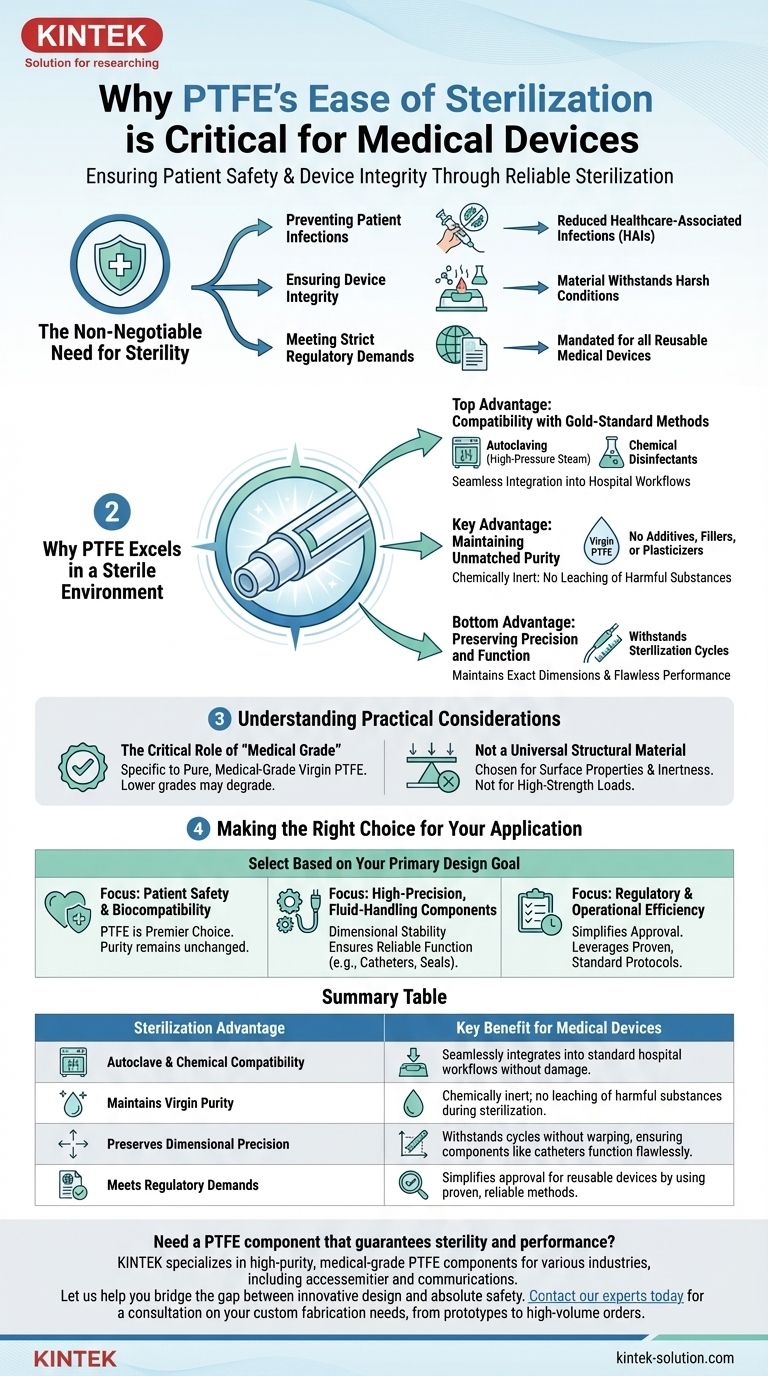

The Non-Negotiable Need for Sterility

Before a medical device can contact a patient, it must be sterile. This fundamental requirement is the bedrock of modern medical safety, and a material's ability to facilitate this is a primary selection criterion.

Preventing Patient Infections

Any contamination on a device, from surgical tools to implants, can introduce dangerous pathogens into the body. This can lead to severe healthcare-associated infections (HAIs), complicating recovery and posing a significant risk to patient health.

Ensuring Device Integrity

The sterilization process itself, which often involves high heat, steam, or potent chemicals, must not compromise the device. A material must be robust enough to withstand these conditions without degrading, warping, or losing its essential functional characteristics.

Meeting Strict Regulatory Demands

Global health authorities mandate that all reusable medical devices be capable of being effectively sterilized. A material that is difficult to sterilize or degrades during the process creates a barrier to regulatory approval and clinical use.

Why PTFE Excels in a Sterile Environment

PTFE’s unique combination of properties makes it exceptionally well-suited for medical applications where sterility is paramount. Its performance goes beyond simple heat resistance.

Compatibility with Gold-Standard Methods

PTFE is fully compatible with the most common and trusted sterilization methods used in healthcare facilities. This includes autoclaving (high-pressure steam) and sterilization with powerful chemical disinfectants. This allows devices made with PTFE to integrate seamlessly into existing hospital workflows.

Maintaining Unmatched Purity

Medical applications typically use virgin PTFE, which contains no additives, fillers, or plasticizers. Because PTFE is chemically inert, the sterilization process won't cause it to leach harmful substances. The material that goes in is the same pure, safe material that comes out.

Preserving Precision and Function

As noted in the references, PTFE is often machined to exact dimensions for critical components like catheters, tubing, and implants. Its ability to withstand sterilization cycles without shrinking, swelling, or warping ensures the device maintains its precise form and flawless performance, eliminating risks of failure.

Understanding the Practical Considerations

While PTFE is an exceptional material, objectivity requires acknowledging its operational context. Its selection is a deliberate engineering choice with specific implications.

The Critical Role of "Medical Grade"

The properties discussed here apply specifically to pure, medical-grade virgin PTFE. Using a lower-grade industrial PTFE that contains fillers or recycled material would completely invalidate its use in a medical device, as those additives could degrade or react during sterilization.

Not a Universal Structural Material

PTFE is chosen for its surface properties, inertness, and purity, not for high-strength structural applications. For load-bearing implants or tools requiring extreme rigidity, other materials like PEEK or surgical-grade metals are used. PTFE's role is often as a critical coating, liner, or precision component.

Making the Right Choice for Your Application

Selecting the right material is about matching its properties to your primary design goal.

- If your primary focus is patient safety and biocompatibility: PTFE is a premier choice because its inertness and purity remain unchanged by proven sterilization methods.

- If your primary focus is high-precision, fluid-handling components: PTFE's dimensional stability through autoclaving ensures that tubes, seals, and catheters will function reliably without risk of failure.

- If your primary focus is regulatory and operational efficiency: Choosing PTFE simplifies the path to approval by leveraging its compatibility with standard, well-documented sterilization protocols used worldwide.

Ultimately, PTFE's reliable sterilizability provides the essential bridge between innovative medical design and the absolute requirement for patient safety.

Summary Table:

| Sterilization Advantage | Key Benefit for Medical Devices |

|---|---|

| Autoclave & Chemical Compatibility | Seamlessly integrates into standard hospital workflows without damage. |

| Maintains Virgin Purity | Chemically inert; no leaching of harmful substances during sterilization. |

| Preserves Dimensional Precision | Withstands cycles without warping, ensuring components like catheters function flawlessly. |

| Meets Regulatory Demands | Simplifies approval for reusable devices by using proven, reliable methods. |

Need a PTFE component that guarantees sterility and performance?

At KINTEK, we specialize in manufacturing high-purity, medical-grade PTFE components—from seals and liners to custom labware—for the semiconductor, medical, and laboratory industries. Our precision machining ensures your devices maintain exact dimensions and integrity through repeated sterilization cycles, safeguarding patient health and meeting strict regulatory standards.

Let us help you bridge the gap between innovative design and absolute safety. Contact our experts today for a consultation on your custom fabrication needs, from prototypes to high-volume orders.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support