In sublimation printing, a Teflon sheet is a critical tool used to protect your equipment and ensure the quality of your final product. Its primary roles are to prevent ink from permanently staining your heat press and to help distribute heat evenly, which is essential for creating vibrant, sharp, and consistent designs.

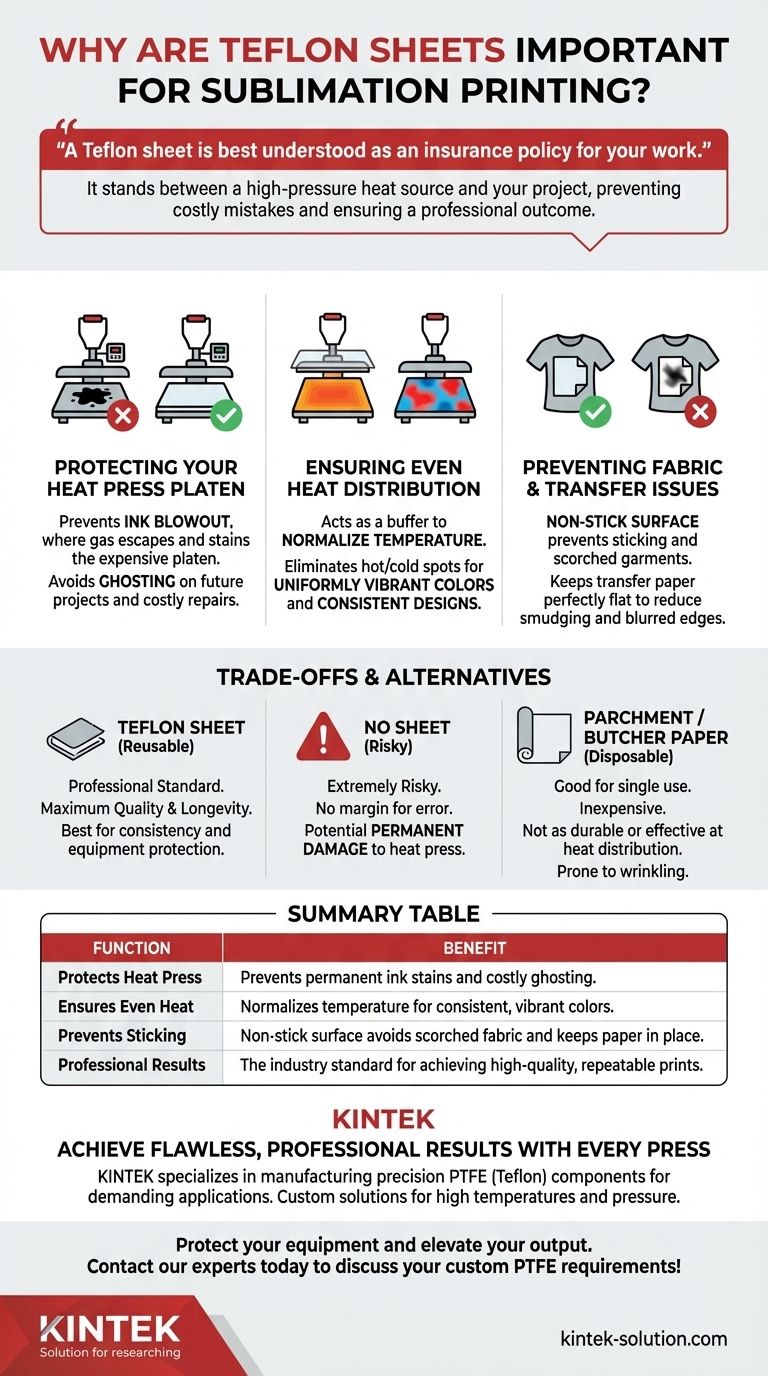

A Teflon sheet is best understood as an insurance policy for your work. It stands between a high-pressure heat source and your project, preventing costly mistakes like stained equipment and ruined garments, ensuring a professional outcome every time.

The Core Functions of a Teflon Sheet in Sublimation

To understand its importance, we need to look at how a Teflon sheet solves the key challenges inherent in the sublimation process. The combination of high heat, pressure, and gaseous ink creates a volatile environment that must be controlled.

Protecting Your Heat Press Platen

The top element of your heat press, the heat platen, is the most critical and expensive component.

Sublimation ink turns into a gas under heat. It's common for this gas to escape around the edges of the transfer paper, an effect known as ink blowout. Without a protective barrier, this ink will permanently bond with the hot surface of your platen, which is often coated with a special non-stick layer that can be ruined.

A stained platen can transfer old ink onto subsequent projects, a problem called ghosting, ruining future prints and requiring costly repairs or replacement.

Ensuring Even Heat Distribution

Consistency is the hallmark of professional-quality printing. The sublimation process is highly sensitive to temperature variations.

Even the best heat presses can have minor hot or cold spots across the platen. A Teflon sheet acts as a buffer, helping to normalize the temperature and distribute the heat more evenly across the entire surface of your design.

This even distribution is what produces uniformly vibrant colors without the blotchy or faded spots that can result from inconsistent heating.

Preventing Fabric and Transfer Issues

The non-stick surface of Teflon is invaluable. It prevents the sublimation paper from sticking to the platen and ensures your garment or substrate doesn't accidentally scorch or adhere to the press.

This smooth surface also helps keep the transfer paper perfectly flat and in place, reducing the chance of smudging or blurred edges in the final print.

Understanding the Trade-offs and Alternatives

While a Teflon sheet is a professional standard, it's important to understand the context of its use and the alternatives that exist.

Can You Sublimate Without a Teflon Sheet?

Technically, yes. Sublimation can be performed without a protective sheet if your settings are perfect and your paper is cut precisely to the design with no bleed.

However, this approach is extremely risky. It leaves no margin for error. A slight misalignment or an unexpected ink blowout could permanently damage your heat press, making it an unwise choice for anyone serious about consistency and protecting their investment.

The Role of Parchment or Butcher Paper

Many printers use uncoated parchment paper or butcher paper as a disposable alternative.

These papers offer good protection against ink blowout for a single use and are very inexpensive. However, they are not as durable, can wrinkle under pressure, and do not distribute heat as effectively as a dedicated Teflon sheet. They are a viable option, but Teflon remains the superior choice for reusability and performance.

Making the Right Choice for Your Goal

Ultimately, the protective layer you use should match your operational goals and commitment to quality.

- If your primary focus is maximum quality and equipment longevity: A reusable Teflon sheet is the non-negotiable industry standard.

- If your primary focus is minimizing costs for occasional hobby use: A fresh sheet of parchment or butcher paper for every press is a workable alternative.

- If you must print without a cover due to a specific circumstance: Proceed with extreme caution, understanding the significant risk to your equipment.

This simple, reusable sheet is one of the most effective tools for elevating your work from amateur to professional.

Summary Table:

| Function | Benefit |

|---|---|

| Protects Heat Press | Prevents permanent ink stains and costly ghosting on the platen. |

| Ensures Even Heat | Normalizes temperature for consistent, vibrant colors without blotches. |

| Prevents Sticking | Non-stick surface avoids scorched fabric and keeps transfer paper in place. |

| Professional Results | The industry standard for achieving high-quality, repeatable prints. |

Achieve Flawless, Professional Results with Every Press

A high-quality Teflon sheet is essential for protecting your investment and ensuring print consistency. For demanding applications in industrial, laboratory, or specialized printing environments, standard sheets may not be enough.

KINTEK specializes in manufacturing precision PTFE (Teflon) components. We understand the critical need for durability, consistent performance, and heat resistance. Whether you need custom-sized Teflon press sheets, liners, or other labware to withstand high temperatures and pressure, we can fabricate a solution tailored to your exact needs—from prototypes to high-volume orders.

Protect your equipment and elevate your output. Contact our experts today to discuss your custom PTFE requirements!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What is the significance of the low friction coefficient in PTFE processing machines? Enhance Quality and Machine Life

- What are the key steps for properly installing PTFE gaskets? Ensure a leak-free seal with our expert guide.

- How do different grades of Teflon (PTFE) affect machining? A Guide to Material Selection and Tooling

- How do PTFE gaskets benefit the mechanical equipment industry? Enhance Equipment Reliability and Longevity

- What types of applications are PTFE piston seals suitable for? The Ultimate Guide for Demanding Environments

- What are the advantages of PTFE balls over metals or alloys? Superior Chemical & Friction Resistance

- What are the primary materials used for oil seals? NBR vs. PTFE for Your Application

- What are the different forms of PTFE sheet gasket materials? Select the Right PTFE for Your Sealing Needs