To handle different loads, bearing pads use specific formulations of Teflon (PTFE). Standard, pure "white" Teflon is specified for applications with lighter loads, while reinforced PTFE composites, such as Fluorogold, are engineered to withstand the significantly higher compressive forces of heavy structural loads.

The key isn't simply using Teflon, but selecting the correct type of Teflon. The choice balances the material's natural low friction against its compressive strength, which is enhanced with fillers for demanding applications.

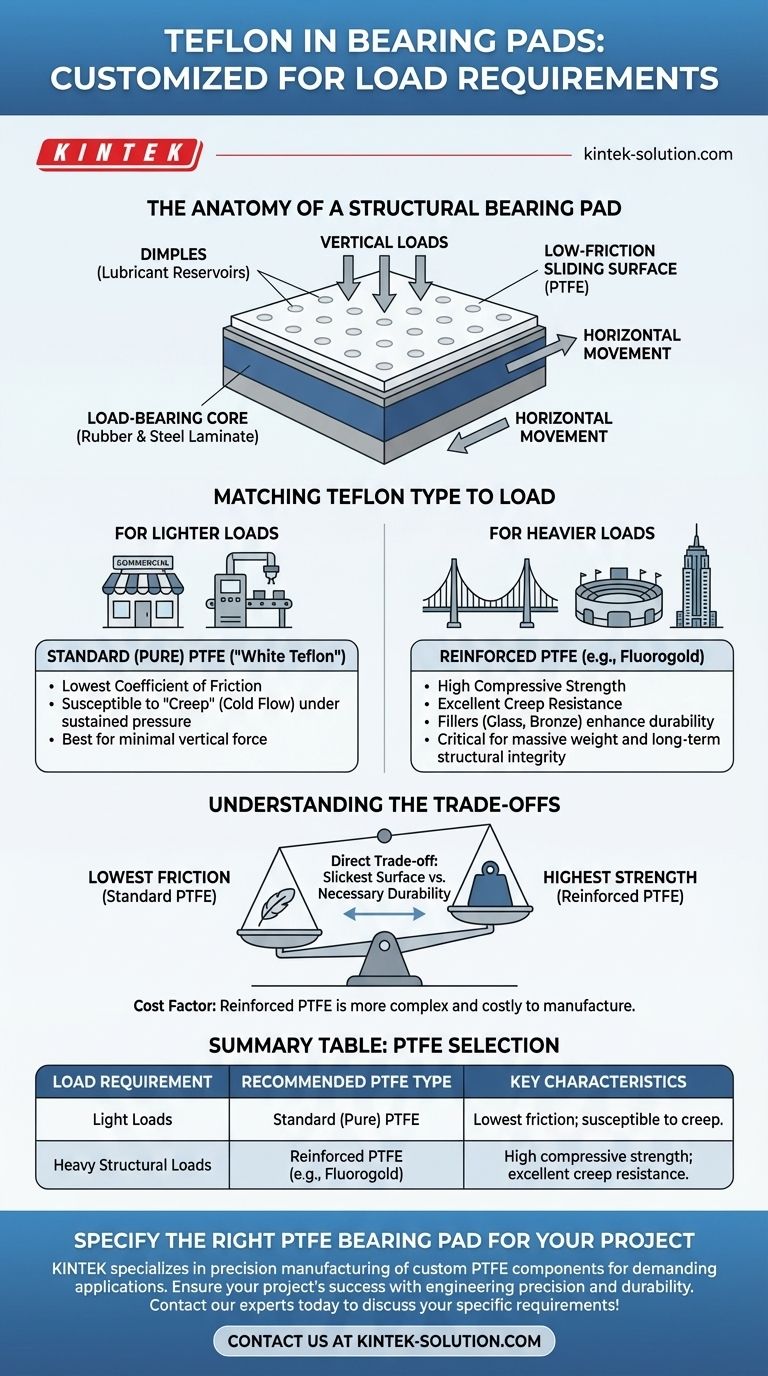

The Anatomy of a Structural Bearing Pad

To understand the role of Teflon, you must first understand the complete system. A modern bearing pad is a composite assembly designed to manage both vertical loads and horizontal movement safely.

The Load-Bearing Core

The foundation of the pad is typically a laminate of natural or chloroprene rubber vulcanized with reinforcing steel plates. This core is engineered to support immense vertical weight and allow for slight rotational movements of the structure it supports.

The Low-Friction Sliding Surface

A thin plate of Polytetrafluoroethylene (PTFE), commonly known by the brand name Teflon, is bonded to the top surface of the rubber and steel pad. This PTFE layer is the critical component that allows for sliding, accommodating movements caused by thermal expansion, contraction, or other dynamic forces.

The Purpose of Dimples

Often, the Teflon surface is dimpled. These indentations serve as reservoirs for lubricants, which can further reduce the coefficient of friction and ensure smooth, predictable movement over the lifespan of the bearing.

Matching the Teflon Type to the Load

The primary distinction in specifying a Teflon bearing pad comes down to the compressive strength of the PTFE layer itself.

For Lighter Loads: Standard PTFE

For applications with relatively light loads, pure, unfilled PTFE (often seen as "white Teflon") is used. Its primary advantage is having one of the lowest coefficients of friction of any solid material. However, it is susceptible to "creep" or cold flow—a slow deformation under sustained pressure.

For Heavier Loads: Reinforced PTFE (Fluorogold)

For significant structural loads, such as those in bridges or large buildings, the PTFE must be reinforced. Materials like Fluorogold are composites where fillers (like glass fiber or bronze powder) are blended into the PTFE.

These fillers dramatically increase the material's compressive strength and its resistance to creep. This allows the bearing to support massive weight without deforming, ensuring long-term structural integrity.

Understanding the Trade-offs

Choosing the right material involves a clear understanding of the engineering compromises between performance and strength.

Friction vs. Compressive Strength

There is a direct trade-off between the lowest possible friction and the highest possible strength. Pure PTFE offers the slickest surface, but reinforced PTFE provides the necessary durability for heavy loads, albeit with a slightly higher (but still very low) coefficient of friction.

Cost and Specification

Reinforced PTFE composites are more complex to manufacture and therefore more costly than standard PTFE. They require precise engineering specifications to ensure the final product meets the demanding requirements of a high-load structural application.

How to Apply This to Your Project

The selection process should be guided by the primary engineering demand of the application.

- If your primary focus is supporting a lightweight structure with minimal vertical force: A standard white PTFE pad is likely the most efficient and cost-effective solution.

- If your primary focus is supporting a heavy structure like a bridge, stadium, or large building: A reinforced PTFE composite like Fluorogold is non-negotiable to handle the high pressure and prevent long-term material failure.

Ultimately, specifying the correct bearing pad is crucial for protecting the structure from the stresses of movement and ensuring its long-term safety.

Summary Table:

| Load Requirement | Recommended PTFE Type | Key Characteristics |

|---|---|---|

| Light Loads | Standard (Pure) PTFE | Lowest coefficient of friction; susceptible to creep. |

| Heavy Structural Loads | Reinforced PTFE (e.g., Fluorogold) | High compressive strength; excellent creep resistance. |

Specify the Right PTFE Bearing Pad for Your Project

Choosing the correct PTFE type is critical for structural integrity and performance. KINTEK specializes in the precision manufacturing of custom PTFE components, including seals, liners, and labware, for the semiconductor, medical, laboratory, and industrial sectors.

Whether you need standard PTFE for light-duty applications or high-strength composites for demanding structural loads, we provide custom fabrication from prototypes to high-volume orders.

Ensure your project's success with components engineered for precision and durability. Contact our experts today to discuss your specific requirements!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What are the installation benefits of PTFE compensators compared to metal alternatives? Achieve Faster, Safer, and More Cost-Effective Installation

- How do PTFE ring gaskets benefit piston engines? Enhance Engine Reliability and Longevity

- Why is tool selection important in the CNC machining of PTFE parts? Achieve Precision and Quality

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- Which adhesives are suitable for bonding PTFE to metal? Achieve a Strong, Reliable Bond

- What are bearing grades of PTFE used for? Achieve High-Performance, Self-Lubricating Components

- What determines the lifespan of a PTFE coating thrust washer in a fishing reel? Maximize Durability & Performance

- What are the advantages of PTFE-coated O-rings? Reduce Friction & Color-Code for Easy Assembly