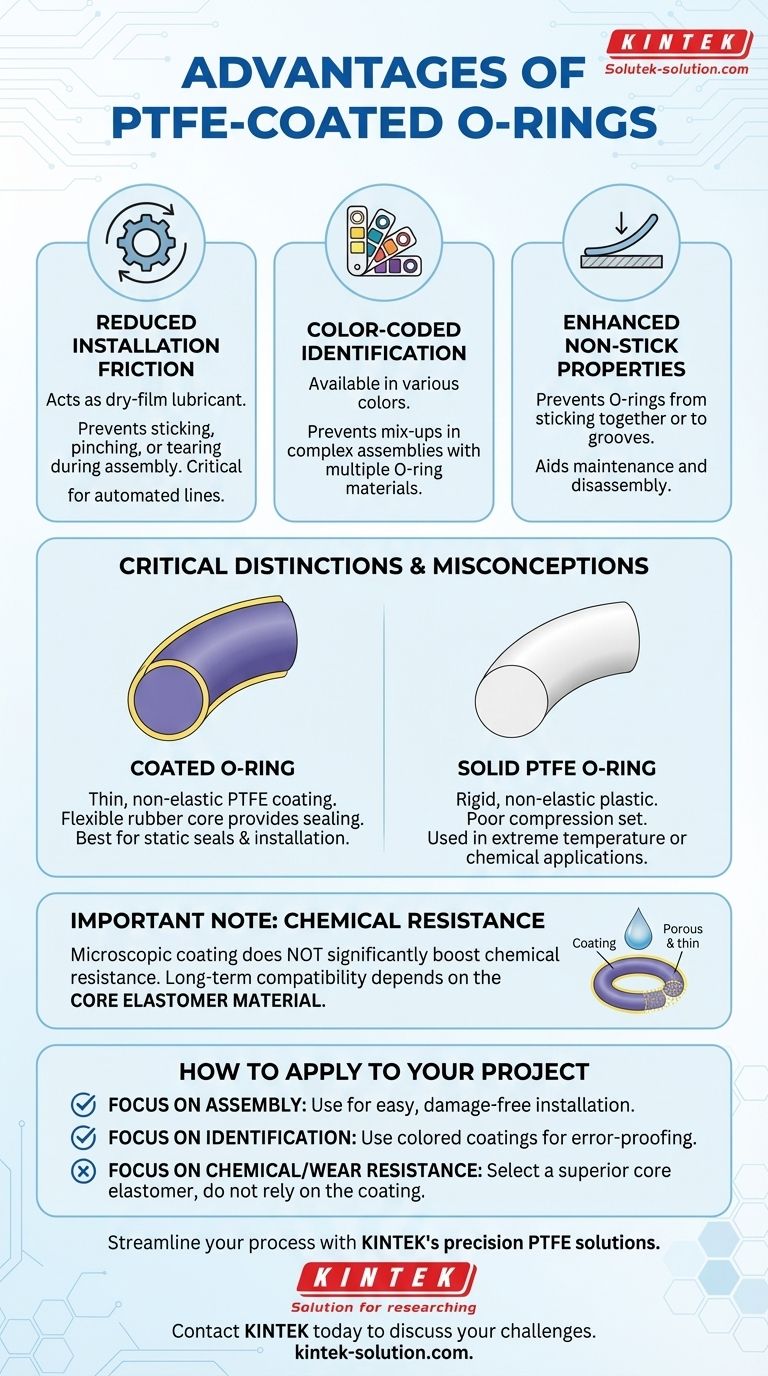

In short, the main advantages of a PTFE-coated O-ring are significantly reduced friction for easier installation and the ability to color-code parts for clear identification. While the PTFE material itself has excellent chemical and temperature resistance, the extremely thin coating offers minimal improvement to the O-ring's overall performance in these areas; the core elastomer material remains the defining factor.

The key takeaway is to view a PTFE coating not as a performance enhancement for the seal itself, but as a valuable surface treatment that solves specific manufacturing and logistical problems, primarily by acting as a dry-film lubricant during assembly.

The Primary Role of a PTFE Coating

A PTFE coating is an incredibly thin layer of Polytetrafluoroethylene applied to the surface of a standard elastomeric O-ring (like NBR, FKM, or EPDM). Its advantages stem from modifying the surface properties of the underlying seal.

Reducing Installation Friction

The most significant benefit is the creation of a low-friction surface. PTFE has one of the lowest coefficients of friction of any solid material.

This "dry lubrication" is critical in automated assembly lines where O-rings must be installed quickly and without damage. It prevents the elastomer from sticking, pinching, or tearing during installation, which is a common failure point.

Enabling Color Identification

PTFE coatings can be produced in a wide variety of distinct colors.

This provides a simple and effective visual method for part identification. In complex assemblies that use multiple O-rings of similar sizes but different materials, color-coding can prevent costly mix-ups and ensure the correct seal is used in the right place.

Enhancing Non-Stick Properties

The non-stick nature of PTFE prevents O-rings from sticking to each other in a bag or automated feeder bowl.

This also aids in maintenance and disassembly, as the O-ring is less likely to adhere to the groove surfaces over time, making it easier to remove and replace.

Understanding the Trade-offs and Misconceptions

It is critical to understand what a PTFE coating is not. Misunderstanding its limitations can lead to seal failure. Its benefits are highly specific and come with clear trade-offs.

It Does Not Significantly Boost Chemical Resistance

A common misconception is that the coating makes the O-ring chemically inert. The coating is microscopic (a few microns thick) and porous.

While PTFE itself is highly resistant to chemicals, the coating is too thin and imperfect to provide a true chemical barrier. The long-term chemical compatibility of the seal is almost entirely determined by the core elastomer material, not the coating.

The Coating Has Poor Wear Resistance

The coating is a surface treatment and is not permanently bonded to the elastomer.

In dynamic applications where the O-ring is subject to rubbing or abrasion, the PTFE coating will quickly flake off and wear away. Its benefits are best realized in static seals or for the single act of installation.

Coated vs. Solid PTFE: A Critical Distinction

Do not confuse a PTFE-coated O-ring with a solid PTFE O-ring. A coated O-ring is a flexible, elastic rubber core with a thin, non-elastic coating. It still compresses and rebounds to create a seal.

A solid PTFE O-ring is a rigid, non-elastic plastic ring. It has very poor "memory" (high compression set) and does not seal well in standard O-ring grooves. They are used in very different, high-temperature, or extreme chemical applications where elasticity is not required.

How to Apply This to Your Project

Choosing the right seal requires matching the technology to your primary goal.

- If your primary focus is simplifying assembly: A PTFE-coated O-ring is an excellent choice, especially in automated or difficult-to-reach installations where its low friction prevents damage.

- If your primary focus is error-proofing your supply chain: Use different colored PTFE coatings to visually distinguish between otherwise identical-looking O-rings made of different materials.

- If your primary focus is long-term chemical or wear resistance: Do not rely on the coating. Instead, select a superior core elastomer (like FFKM or FKM) that is inherently resistant to your specific operating conditions.

Ultimately, view a PTFE coating as a process aid for installation and identification, not a fundamental performance upgrade for the seal in service.

Summary Table:

| Advantage | Key Benefit | Best For |

|---|---|---|

| Reduced Friction | Acts as a dry lubricant for easy, damage-free installation | Automated assembly lines, difficult-to-reach installations |

| Color-Coding | Visual identification to prevent part mix-ups | Complex assemblies with multiple O-ring types |

| Non-Stick Surface | Prevents O-rings from sticking to each other or grooves | Maintenance, disassembly, and automated feeding systems |

| Note | Coating is thin; chemical/wear resistance is determined by the core elastomer | Static seals or for installation aid only |

Struggling with O-ring installation or identification errors? KINTEK specializes in precision PTFE components, including custom-coated O-rings designed to solve your specific assembly challenges. Our expertise in custom fabrication for the semiconductor, medical, laboratory, and industrial sectors ensures you get a reliable, high-performance solution—from prototypes to high-volume orders.

Contact KINTEK today to discuss how our PTFE-coated O-rings can streamline your process and improve reliability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What advancements are being made in recycling Teflon scrap? From Micronization to Upcycling

- What types of products are typically made through PTFE paste extrusion? High-Performance Tubing, Hoses & Wire Insulation

- What performance advantages do PTFE rotary shaft seals provide for machinery? Achieve Peak Efficiency & Reliability

- How do the non-stick properties of PTFE oil seals contribute to their performance? Ensure Long-Term Reliability in Harsh Conditions

- What are the standard thickness options for PTFE sheets? Choose the Right Thickness for Your Application

- What are the symptoms of a leaking PTFE butterfly valve? Identify External & Internal Leaks

- In which industries are PTFE compensators commonly used? Essential for Corrosive & High-Purity Systems

- What are the tensile strengths of PTFE and graphite packing? Choosing the Right Material for Your Application