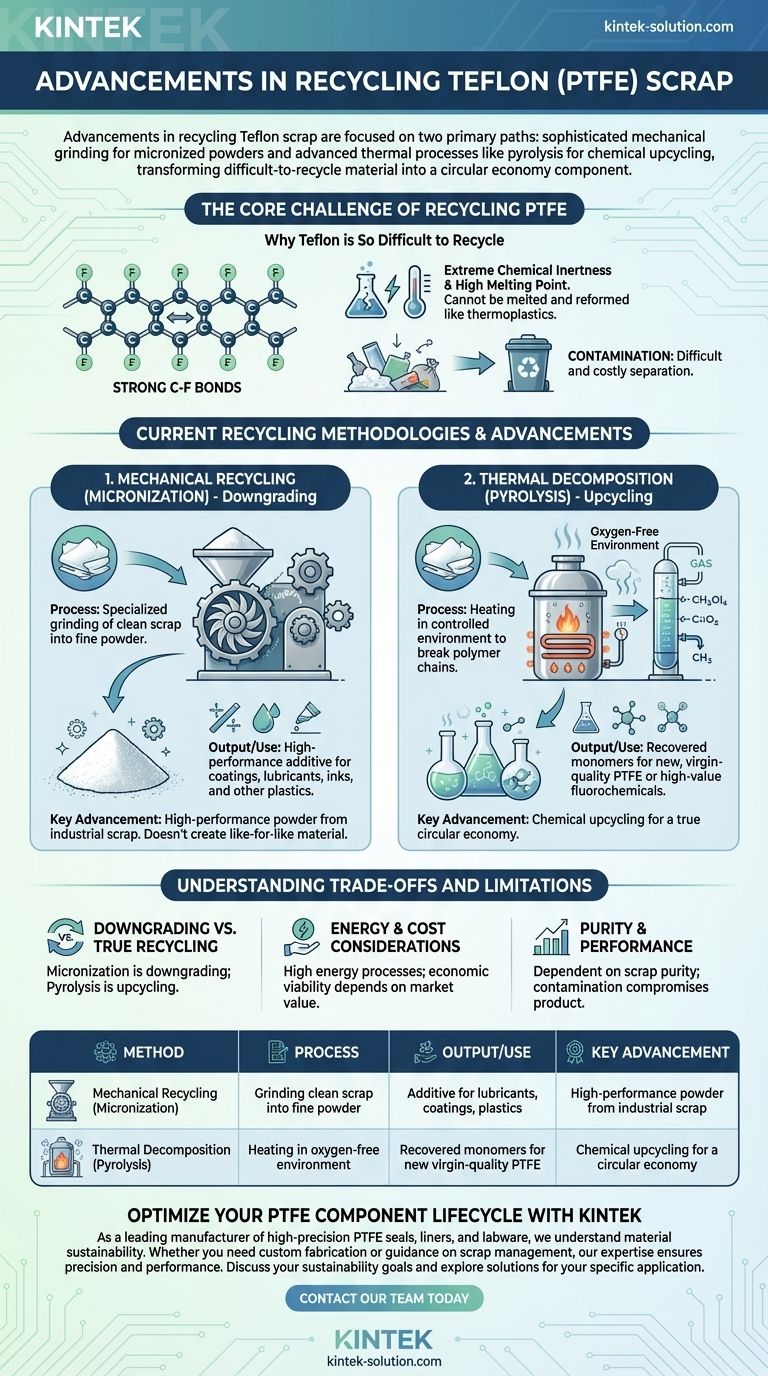

In short, advancements in recycling Teflon scrap are primarily focused on two paths. These are sophisticated mechanical grinding to produce "micronized" powders for reuse as additives, and advanced thermal processes like pyrolysis that break the material down into its chemical precursors for upcycling. These methods aim to transform a notoriously difficult-to-recycle material into a valuable component of a circular economy.

While Teflon's extreme durability makes it a high-performance material, this same chemical inertness is precisely what makes it so challenging to recycle. The key advancements are not in "melting it down" like common plastics, but in either physically repurposing it or chemically deconstructing it.

The Core Challenge of Recycling Teflon (PTFE)

Polytetrafluoroethylene (PTFE), the material branded as Teflon, is a fluoropolymer. Its unique properties stem from the incredibly strong bonds between its carbon and fluorine atoms, which presents a significant hurdle for traditional recycling.

The Chemical Inertness of PTFE

The carbon-fluorine bond is one of the strongest in organic chemistry. This is what gives PTFE its non-stick quality, chemical resistance, and high-temperature tolerance.

However, this stability means it cannot be melted and reformed like thermoplastics such as PET or HDPE. It has an extremely high melting point and viscosity, which prevents it from being easily re-molded.

The Problem of Contamination

PTFE scrap from industrial processes or end-of-life products is often contaminated with other materials. Because of its inertness, separating these contaminants is difficult and costly, which can degrade the quality of any potential recycled product.

Current Recycling Methodologies and Advancements

Engineers have developed specialized techniques to reclaim value from PTFE scrap. These methods sidestep the challenges of melt-processing by treating the material in other ways.

Mechanical Recycling (Micronization)

The most common and commercially viable method is micronization. This process uses specialized grinding and milling technologies to break down clean PTFE scrap into a fine powder.

This recycled powder is not used to create new, solid PTFE parts. Instead, it serves as a high-performance additive in other materials, such as coatings, lubricants, inks, and other plastics to impart some of PTFE's desirable low-friction properties.

Thermal Decomposition (Upcycling)

A more advanced approach involves breaking PTFE down with heat in a controlled, oxygen-free environment—a process called pyrolysis.

This method "unzips" the long polymer chains back into their constituent chemical building blocks, primarily valuable fluorochemical monomers. These recovered monomers can then be purified and used to produce new, virgin-quality PTFE or other high-value fluorochemicals. This is a form of upcycling.

The Role of Material Recovery Technologies

Supporting these core methods are advancements in material recovery. Sophisticated sorting, cleaning, and preparation technologies are crucial for ensuring the scrap input is pure enough for either micronization or pyrolysis to be effective and economically feasible.

Understanding the Trade-offs and Limitations

While these advancements are promising, it is critical to understand their practical limitations. PTFE recycling is not yet a closed-loop system in the traditional sense.

Downgrading vs. True Recycling

Micronization is technically a form of downcycling. The recycled PTFE powder is used as a lower-value additive rather than to create new, equivalent PTFE products. While it effectively prevents landfilling, it doesn't create a like-for-like material.

Energy and Cost Considerations

Both micronization and pyrolysis are energy-intensive processes. The cost of collection, sorting, and processing must be carefully weighed against the market value of the resulting recycled powder or recovered chemicals to ensure economic viability.

Purity and Performance

The performance of recycled PTFE depends heavily on the purity of the scrap feedstock. Any contamination can compromise the final product, which is why sourcing clean, well-segregated scrap from industrial manufacturing is far more common than post-consumer recycling.

Applying This to Your Sustainability Strategy

Evaluating PTFE recycling requires aligning your goals with the available technologies.

- If your primary focus is waste reduction: Using micronized PTFE as an additive in your products is a viable and established way to incorporate recycled content and divert industrial scrap from landfills.

- If your primary focus is creating new, high-performance PTFE: The technology to pursue is chemical recycling via pyrolysis, which can recover monomers to produce virgin-quality material, supporting a true circular model.

Ultimately, the ability to reclaim and reuse PTFE is a significant step forward in making this valuable material more sustainable.

Summary Table:

| Method | Process | Output/Use | Key Advancement |

|---|---|---|---|

| Mechanical Recycling (Micronization) | Grinding clean scrap into fine powder | Additive for lubricants, coatings, plastics | High-performance powder from industrial scrap |

| Thermal Decomposition (Pyrolysis) | Heating in oxygen-free environment to break polymer chains | Recovered monomers for new virgin-quality PTFE | Chemical upcycling for a circular economy |

Optimize your PTFE component lifecycle with KINTEK.

As a leading manufacturer of high-precision PTFE seals, liners, and labware for the semiconductor, medical, and industrial sectors, we understand the importance of material sustainability. Whether you need custom-fabricated components from prototypes to high-volume orders or guidance on managing PTFE scrap from your processes, our expertise ensures precision and performance.

Let's discuss how our capabilities can support your sustainability goals. Contact our team today to explore solutions for your specific application.

Visual Guide

Related Products

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

People Also Ask

- What are the key applications of the PTFE bottle? Ensure Chemical Safety and Sample Purity

- What are the temperature limits for the PTFE bottle? Ensure Safety from -200°C to 260°C

- How does the PTFE bottle perform in terms of chemical resistance? Unmatched Protection for Harsh Chemicals

- What are the characteristics of narrow mouth PTFE laboratory bottles? Superior Chemical Resistance & Purity

- What makes the PTFE bottle durable? Unmatched Chemical & Thermal Stability for Demanding Applications