At their core, narrow mouth PTFE laboratory bottles are defined by three primary characteristics: near-total chemical inertness, an exceptionally wide temperature tolerance, and a robust physical design. Made from 100% Polytetrafluoroethylene (PTFE), these bottles are purpose-built for safely handling highly corrosive reagents and for use in extreme temperature applications where glass or standard plastics would fail.

The decision to use a narrow mouth PTFE bottle is not about general storage; it is a specific choice for applications demanding the highest level of chemical resistance and purity, particularly when precise, controlled pouring of aggressive liquids is required.

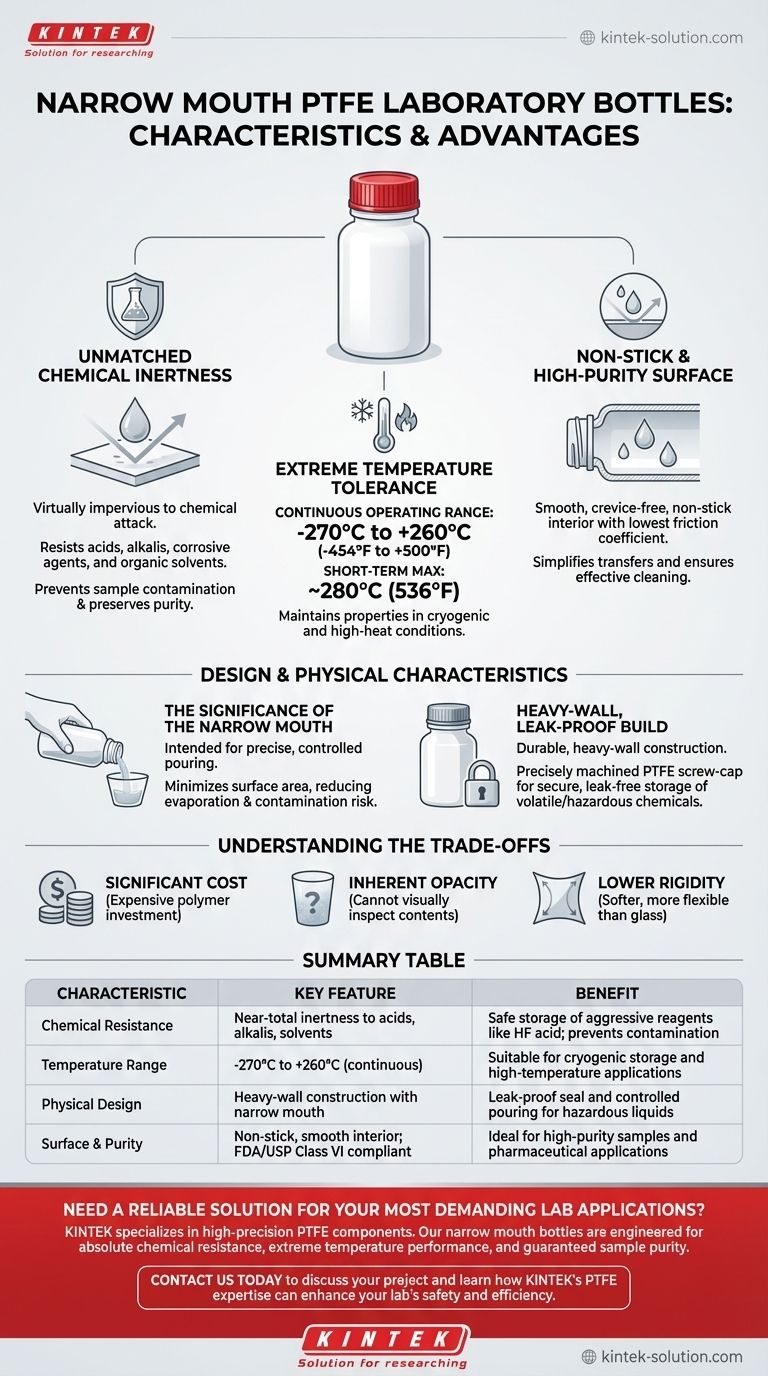

The Core Properties of PTFE Construction

The unique value of these bottles comes directly from the material they are made of. PTFE is a high-performance fluoropolymer with a combination of properties that make it invaluable for critical laboratory work.

Unmatched Chemical Inertness

PTFE is virtually impervious to chemical attack. It exhibits outstanding resistance to almost all acids, alkalis, corrosive agents, and organic solvents.

This inertness ensures that the bottle will not degrade and, just as importantly, that it will not leach contaminants into the stored sample, preserving its purity.

Extreme Temperature Tolerance

These bottles are suitable for an incredibly broad range of temperatures. They maintain their properties in both cryogenic conditions and at high heat.

The typical continuous operating range is from -270°C to +260°C (-454°F to +500°F), with a maximum short-term use temperature of around 280°C (536°F).

Non-Stick and High-Purity Surface

The interior surface of a PTFE bottle is completely smooth, crevice-free, and non-stick. This is due to PTFE having one of the lowest coefficients of friction of any solid.

This property prevents materials from sticking to the walls, which simplifies transfers of valuable samples and makes cleaning highly effective.

Design and Physical Characteristics

Beyond the raw material, the physical design of the bottle is engineered for safety and performance in demanding environments.

The Significance of the Narrow Mouth

The "narrow mouth" design is a key functional feature. It is specifically intended for the controlled pouring of liquids.

This design minimizes the surface area of the liquid exposed to the air, reducing evaporation and contamination risk. It also provides better directional control for pouring into vessels with small openings.

Heavy-Wall, Leak-Proof Build

These bottles feature a heavy-wall construction, making them durable and resistant to physical damage.

Combined with a precisely machined PTFE screw-cap, this robust build ensures a secure, leak-free seal for storing even the most volatile or hazardous chemicals.

Regulatory Compliance

Many high-quality PTFE bottles conform to FDA and USP Class VI requirements. This makes them suitable for sensitive applications in the pharmaceutical, biotechnology, and food science fields where non-toxicity and purity are paramount.

Understanding the Trade-offs

While PTFE offers superior performance, it's a specialized material with practical limitations that make it unsuitable for every application.

Significant Cost

PTFE is an expensive polymer. These bottles represent a significant cost investment compared to common labware made of glass, polypropylene (PP), or high-density polyethylene (HDPE).

Inherent Opacity

PTFE is opaque, meaning you cannot see the contents of the bottle. This makes it impossible to visually check the volume or observe the physical state of the stored chemical without opening it.

Lower Rigidity

Compared to glass, PTFE is a softer, more flexible material. While durable, it does not have the same structural rigidity, which can be a factor in some automated handling systems.

Making the Right Choice for Your Goal

Select a narrow mouth PTFE bottle when the risks associated with chemical incompatibility, temperature, or contamination outweigh the higher cost.

- If your primary focus is storing highly corrosive reagents: PTFE is the definitive choice for materials like hydrofluoric acid, fuming nitric acid, or aggressive solvents that would destroy other containers.

- If you are working with extreme temperatures: These bottles are essential for applications ranging from cryogenic storage in liquid nitrogen to high-temperature digestions.

- If you require controlled pouring of valuable or hazardous liquids: The narrow mouth design provides the precision and safety needed to minimize spills and reduce exposure.

- If your work demands absolute purity: The inert, non-leaching, and non-stick surface ensures the integrity of high-purity standards and trace-analysis samples.

Ultimately, a narrow mouth PTFE bottle is an investment in safety, control, and sample integrity for the most demanding laboratory conditions.

Summary Table:

| Characteristic | Key Feature | Benefit |

|---|---|---|

| Chemical Resistance | Near-total inertness to acids, alkalis, and solvents | Safe storage of aggressive reagents like HF acid; prevents contamination |

| Temperature Range | -270°C to +260°C (continuous) | Suitable for cryogenic storage and high-temperature applications |

| Physical Design | Heavy-wall construction with narrow mouth | Leak-proof seal and controlled pouring for hazardous liquids |

| Surface & Purity | Non-stick, smooth interior; FDA/USP Class VI compliant | Ideal for high-purity samples and pharmaceutical applications |

Need a reliable solution for your most demanding lab applications?

At KINTEK, we specialize in manufacturing high-precision PTFE components, including laboratory bottles, seals, liners, and custom labware. Our narrow mouth PTFE bottles are engineered for semiconductor, medical, pharmaceutical, and industrial labs that require absolute chemical resistance, extreme temperature performance, and guaranteed sample purity.

We offer custom fabrication from prototypes to high-volume orders, ensuring your specific requirements for material integrity and design are met.

Contact us today to discuss your project and learn how KINTEK's PTFE expertise can enhance your lab's safety and efficiency.

Visual Guide

Related Products

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- PTFE Chemical Solvent Sampling Spoon

People Also Ask

- What customization options are available for PTFE-lined bottle caps? Tailor Caps for Chemical & Temperature Resistance

- How does the PTFE bottle perform in terms of chemical resistance? Unmatched Protection for Harsh Chemicals

- What are the best practices for using PTFE syringe filters? Achieve Pure, Reliable Filtration

- What factors should be considered when selecting a PTFE shovel for laboratory use? Ensure Chemical Inertness & Sample Integrity

- Why is vial type and size compatibility important for PTFE-coated septums? Ensure a Perfect Seal for Reliable Results

- In which industries are PTFE lined caps commonly used? Ensure Product Purity & Chemical Resistance

- What are the typical applications of PTFE filters in scientific filtration? Master Harsh Chemical and Gas Filtration

- What advantages do PTFE syringe filters offer in laboratory settings? Unmatched Chemical Resistance & Purity