The importance of vial and septum compatibility is foundational to analytical accuracy because it dictates the quality of the seal. An improper fit between a PTFE-coated septum and a vial is a primary cause of leaks, sample evaporation, and contamination. This directly compromises sample integrity and leads to unreliable, non-reproducible results.

Choosing the correct vial and septum is not a minor detail; it is a foundational step for ensuring analytical integrity. An improper fit compromises the seal, leading to sample loss, contamination, and unreliable results that undermine the entire experiment.

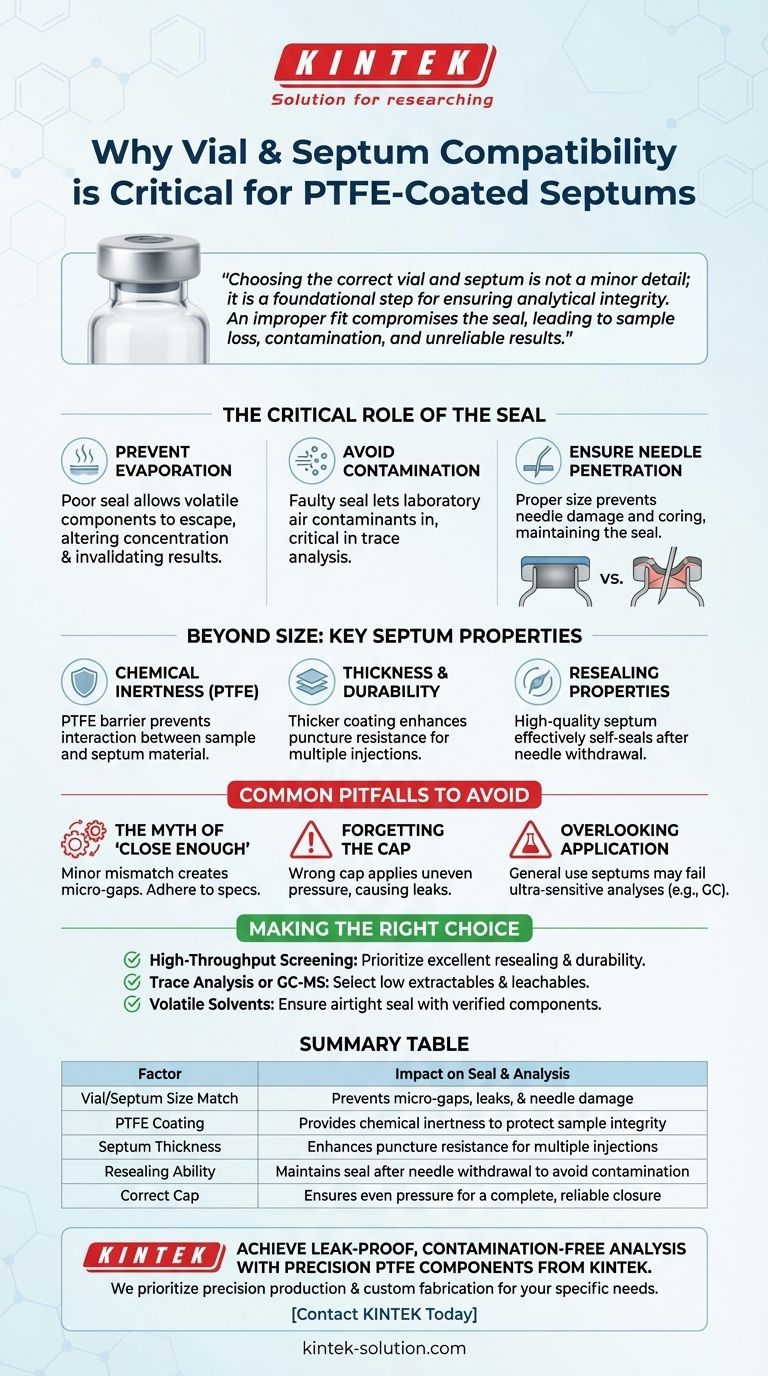

The Critical Role of the Septum-Vial Seal

A septum's primary function is to act as a barrier, protecting the sample from the outside environment while allowing a needle to access it. This function is entirely dependent on a perfect mechanical seal with the vial.

Preventing Sample Evaporation

A poor seal creates a pathway for volatile components of your sample to escape into the atmosphere. This alters the sample's concentration, skewing quantitative results and making them invalid.

Avoiding Environmental Contamination

Just as components can escape, contaminants from the laboratory air can enter the vial through a faulty seal. This is especially critical in trace analysis, where even minute impurities can interfere with the detection of your target analytes.

Ensuring Consistent Needle Penetration

Properly sized septums ensure that an autosampler needle pierces the septum cleanly and in a consistent location. An oversized or undersized septum can cause the needle to bend, break, or "core" the septum (tearing out a piece), which destroys the seal and can clog the needle.

Beyond Size: Factors for a Robust System

While physical dimensions are the starting point, several other properties of the septum are critical for maintaining a closed and non-reactive analytical system.

The Chemical Inertness of PTFE

The Polytetrafluoroethylene (PTFE) coating is essential for its chemical inertness. It creates a barrier that prevents any interaction between the sample and the septum material (often silicone), ensuring your sample's composition remains unchanged.

Septum Thickness and Durability

The thickness of the PTFE coating contributes directly to its puncture resistance. A thicker, more durable septum can withstand multiple injections without failing, which is crucial for high-throughput analysis and for maintaining the seal over time.

Resealing Properties

A high-quality septum, when correctly fitted, will effectively self-seal after the needle is withdrawn. This property is vital for preventing the issues of evaporation and contamination, especially when a vial is analyzed multiple times.

Common Pitfalls to Avoid

Achieving a reliable seal requires a systems-based approach. Focusing only on one component while ignoring others is a frequent source of error.

The Myth of "Close Enough"

Using a septum that seems to "mostly fit" is a significant risk. Even a minor mismatch in diameter or design can create micro-gaps that compromise the entire analysis. Always adhere to the vial manufacturer's specifications.

Forgetting the Cap

The cap is the third component of the sealing system. Using the wrong cap can apply uneven pressure to the septum, creating a channel for leaks even if the vial and septum are technically compatible.

Overlooking Application Demands

The needs of the analysis dictate the best choice. For example, a septum suitable for general use may not be appropriate for ultra-sensitive gas chromatography (GC), which demands minimal extractables to avoid interfering peaks.

Making the Right Choice for Your Analysis

To ensure reliable data, select your consumables based on the specific goals of your experiment.

- If your primary focus is high-throughput screening: Prioritize septums with excellent resealing properties and proven durability to withstand multiple injections without failure.

- If your primary focus is trace analysis or GC-MS: Select septums certified for low extractables and leachables to prevent chemical interference and ensure the cleanest possible baseline.

- If your primary focus is working with volatile solvents: Double-check that the septum, cap, and vial combination provides a verified, airtight seal to prevent evaporative loss and concentration changes.

Ultimately, treating the vial, cap, and septum as a single integrated system is the key to achieving reproducible and trustworthy analytical data.

Summary Table:

| Factor | Impact on Seal & Analysis |

|---|---|

| Vial/Septum Size Match | Prevents micro-gaps, leaks, and needle damage |

| PTFE Coating | Provides chemical inertness to protect sample integrity |

| Septum Thickness | Enhances puncture resistance for multiple injections |

| Resealing Ability | Maintains seal after needle withdrawal to avoid contamination |

| Correct Cap | Ensures even pressure for a complete, reliable closure |

Achieve leak-proof, contamination-free analysis with precision PTFE components from KINTEK.

Whether you are working in semiconductor manufacturing, medical research, or a specialized laboratory, the integrity of your samples is paramount. KINTEK manufactures high-quality PTFE-coated septums, seals, liners, and labware designed for exact compatibility with your vials and analytical instruments.

We prioritize precision production and offer custom fabrication from prototypes to high-volume orders to meet your specific application demands, including trace analysis and high-throughput screening.

Ensure your analytical data is reliable and reproducible. Contact KINTEK today to discuss your PTFE component needs and request a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts