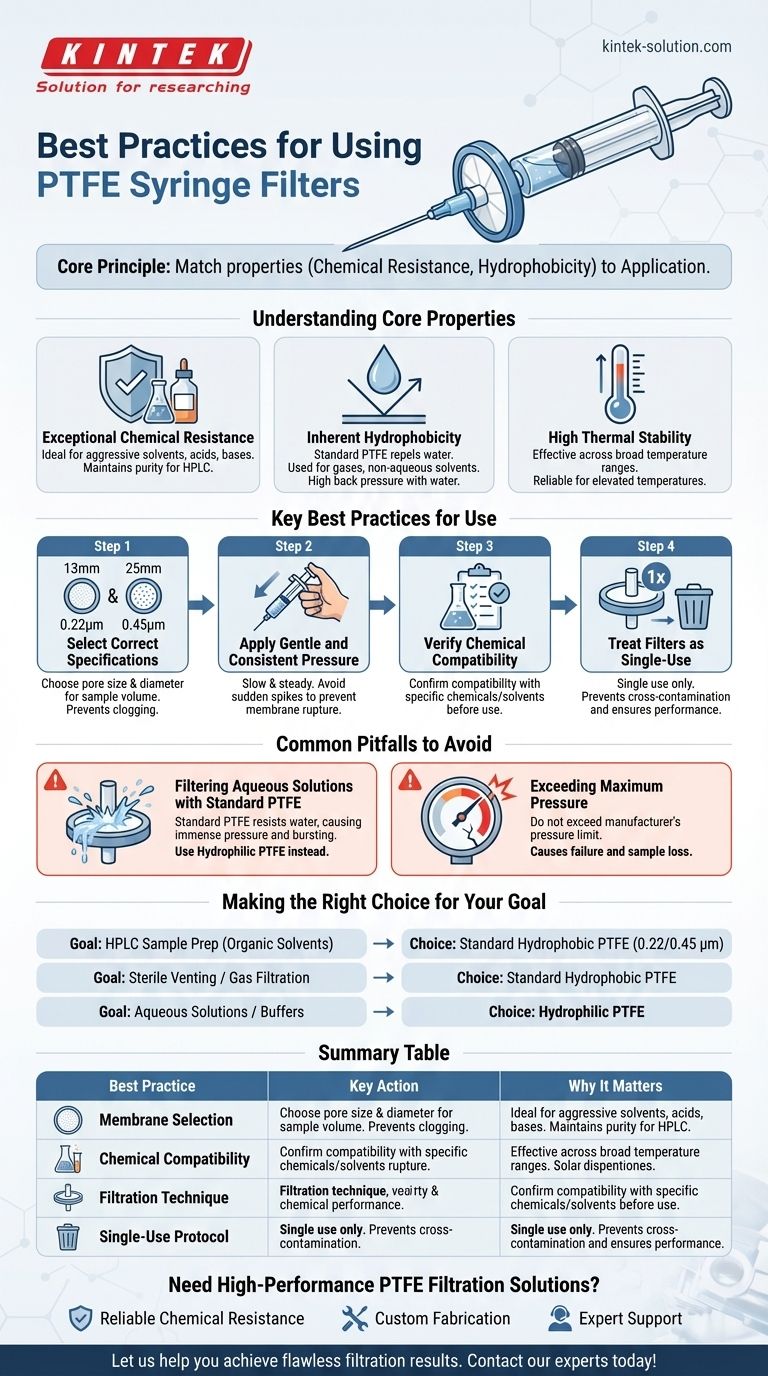

To properly use a PTFE syringe filter, you must select the correct pore size and diameter for your sample volume, apply slow and steady pressure to avoid membrane rupture, and leverage its chemical resistance for aggressive solvents or gas filtration. Because standard PTFE is naturally hydrophobic, it is critical to use it only for non-aqueous liquids unless you are using a specially treated hydrophilic version.

The core principle behind using PTFE filters effectively is matching their unique properties—strong chemical resistance and inherent hydrophobicity—to the right application. Misunderstanding these properties, particularly when dealing with water-based solutions, is the most common source of filtration failure.

Understanding the Core Properties of PTFE

Polytetrafluoroethylene (PTFE) is not a universal filter material. Its specific characteristics make it exceptional for certain tasks and completely unsuitable for others.

Exceptional Chemical Resistance

PTFE is one of the most chemically inert polymers available. This makes it the ideal choice for filtering samples that contain aggressive organic solvents, strong acids, or bases.

Unlike other membrane materials that might degrade or leach contaminants, PTFE maintains its integrity, ensuring the purity of your filtrate. This is critical for sensitive analytical techniques like HPLC.

Inherent Hydrophobicity

Standard PTFE membranes are hydrophobic, meaning they naturally repel water. This property makes them excellent for filtering gases and preventing aqueous aerosols from passing.

This is also why they are used to degas or clarify non-aqueous solvents. However, it means they will resist the passage of water-based liquids, creating very high back pressure. For aqueous solutions, a surface-treated hydrophilic PTFE filter is required.

High Thermal Stability

PTFE functions effectively across a broad temperature range. This stability makes it a reliable option for processes that involve filtration at elevated temperatures where other materials might fail.

Key Best Practices for Use

Adhering to a few procedural best practices ensures you achieve efficient filtration, prevent sample loss, and protect your equipment.

Select the Correct Filter Specifications

The filter's pore size (e.g., 0.22 µm or 0.45 µm) determines the size of particles it will remove. The diameter (e.g., 13 mm or 25 mm) corresponds to the sample volume you can process without excessive back pressure.

Choosing the wrong size can lead to membrane clogging, slow filtration rates, or even cause the filter housing to burst under pressure.

Apply Gentle and Consistent Pressure

A common mistake is applying too much force to the syringe plunger too quickly. This sudden pressure spike can easily tear the delicate filter membrane inside.

Always apply smooth, gradual pressure. If you feel significant resistance, stop. It may indicate the filter is clogged or incompatible with your sample.

Verify Chemical Compatibility

While PTFE is broadly resistant, it is always a best practice to confirm its compatibility with your specific chemical mixture, especially with complex or novel solvents.

Treat Filters as Single-Use

PTFE syringe filters are designed for a single use. Reusing a filter risks cross-contamination between samples and unpredictable performance due to partial clogging from the previous filtration.

Common Pitfalls to Avoid

Understanding the limitations of PTFE is just as important as knowing its strengths. Avoiding these common errors will prevent failed experiments and wasted samples.

Filtering Aqueous Solutions with Standard PTFE

The most frequent mistake is attempting to filter a water-based solution through a standard, hydrophobic PTFE filter. The membrane will resist the liquid, creating immense back pressure that can cause the filter to burst.

For aqueous samples, you must use a filter specifically marked as hydrophilic PTFE or pre-wet a standard PTFE filter with a solvent like methanol or isopropanol before use.

Exceeding Maximum Pressure

Every syringe filter has a maximum operating pressure specified by the manufacturer. Exceeding this limit, often by using a small-diameter filter for a large or viscous sample, can cause the housing to fail and lead to sample loss.

Making the Right Choice for Your Goal

Select your filter based on a clear understanding of your sample and objective.

- If your primary focus is HPLC sample prep with organic solvents: Choose a standard hydrophobic PTFE filter with a 0.22 µm or 0.45 µm pore size to ensure chemical purity.

- If your primary focus is sterile venting or gas filtration: A standard hydrophobic PTFE filter is the ideal choice to allow gas exchange while blocking aqueous contaminants.

- If your primary focus is filtering aqueous solutions or buffers: You must use a specifically designated hydrophilic PTFE filter to allow the sample to pass through without resistance.

Ultimately, mastering the use of PTFE filters comes down to aligning their specific chemical properties with the demands of your application.

Summary Table:

| Best Practice | Key Action | Why It Matters |

|---|---|---|

| Membrane Selection | Choose pore size (0.22/0.45 µm) and diameter for your sample volume. | Prevents clogging, ensures efficient filtration, and avoids high back pressure. |

| Chemical Compatibility | Use standard PTFE for aggressive solvents; use hydrophilic PTFE for aqueous solutions. | Maintains sample purity and prevents membrane failure due to incompatibility. |

| Filtration Technique | Apply slow, steady pressure with the syringe plunger. | Protects the delicate membrane from rupture and ensures consistent flow. |

| Single-Use Protocol | Use each filter once and then dispose of it. | Eliminates risk of cross-contamination and guarantees reliable performance. |

Need High-Performance PTFE Filtration Solutions?

KINTEK specializes in the precision manufacturing of PTFE components, including syringe filters, seals, and labware. Our products are engineered for the demanding requirements of the semiconductor, medical, laboratory, and industrial sectors.

We offer:

- Reliable Chemical Resistance: Ensure the purity of your samples, even with aggressive solvents.

- Custom Fabrication: From prototype development to high-volume production runs.

- Expert Support: Get guidance on selecting the right filter for your specific application.

Let us help you achieve flawless filtration results. Contact our experts today to discuss your needs!

Visual Guide

Related Products

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- How does PTFE behave in terms of chemical inertness? Unmatched Resistance for Demanding Applications

- What makes the PTFE bottle durable? Unmatched Chemical & Thermal Stability for Demanding Applications

- How does PTFE react to ammonia? Discover Its Superior Chemical Resistance

- What are the key features of PTFE-lined bottle caps? Ensure Chemical Integrity and Purity for Your Samples

- What are the chemical resistance properties of PTFE labware? The Ultimate Guide to Inert Labware