In short, PTFE lined caps are essential in any industry where product purity, aggressive chemical containment, and a reliable seal are paramount. They are most commonly used in pharmaceuticals, laboratory testing, chemical processing, and food and beverage manufacturing due to the liner's exceptional non-reactivity and resistance to corrosion.

The decision to use a PTFE lined cap is not about the cap itself, but about protecting what's inside the container. Its unparalleled chemical resistance and non-stick, non-leaching surface make it the default choice for applications ranging from preserving sensitive biological samples to safely storing highly corrosive acids.

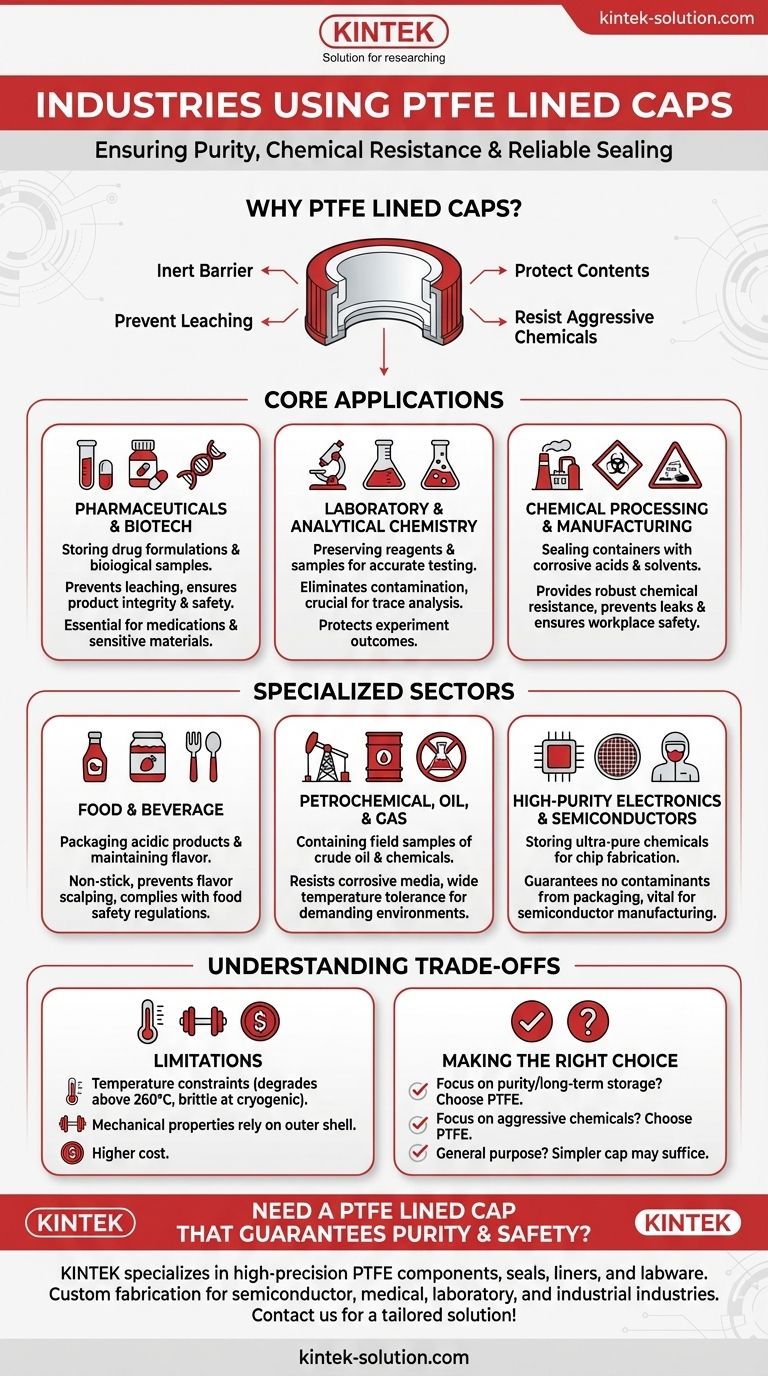

Core Applications Driven by Chemical Inertness

The primary value of PTFE (polytetrafluoroethylene) is its status as one of the most chemically inert polymers known. This property directly drives its adoption in critical industries.

Pharmaceuticals and Biotechnology

In pharmaceuticals, product integrity is absolute. A container cannot be allowed to interact with its contents.

PTFE liners create an inert barrier, preventing any chemicals from leaching out of the cap material and into the drug formulation. This is crucial for maintaining the stability, efficacy, and safety of medications.

Laboratory and Analytical Chemistry

Labs rely on the purity of samples, reagents, and chemical standards for accurate results.

Using PTFE lined caps ensures that stored materials are not contaminated over time. This is especially vital in trace analysis, where even microscopic impurities can skew experimental outcomes.

Chemical Processing and Manufacturing

This sector frequently deals with highly corrosive acids, bases, and aggressive organic solvents.

PTFE lined caps provide a robust and safe sealing solution for containers holding these hazardous materials. The liner prevents the chemical from attacking the cap's structural material, avoiding leaks and ensuring workplace safety.

Broader Use Cases in Specialized Sectors

The properties that make PTFE essential in labs and pharma also make it valuable in other demanding environments.

Food and Beverage

PTFE is used for its non-stick properties and compliance with food safety regulations.

In this context, PTFE liners prevent flavor or color "scalping," where the cap material absorbs elements from the product. They also provide a tight seal for acidic products like sauces or dressings.

Petrochemical, Oil, and Gas

While more common in valves and seals, the principles apply to container caps for field samples.

PTFE's resistance to corrosive media and its wide temperature tolerance make it suitable for containing samples of crude oil, refined products, and various processing chemicals for analysis.

High-Purity Electronics and Semiconductors

Semiconductor manufacturing requires extreme cleanliness, as the smallest contaminant can ruin a microchip.

PTFE lined containers are used to store and transport the ultra-pure chemicals and solvents required in the fabrication process, guaranteeing no contaminants are introduced from the packaging.

Understanding the Trade-offs

While highly effective, PTFE lined caps are not a universal solution. Understanding their limitations is key to using them correctly.

Temperature Constraints

PTFE has an impressive operating temperature range, but it is not infinite. It can become brittle at cryogenic temperatures and can begin to degrade at very high temperatures (typically above 260°C or 500°F).

Mechanical Properties

PTFE is a relatively soft material. The liner provides the chemical barrier, but the structural integrity of the cap comes from the outer shell, which is usually a more rigid plastic like polypropylene. The cap's performance depends on this composite structure.

Cost Considerations

PTFE lined caps are significantly more expensive than standard, unlined polyethylene or polypropylene caps. Their use is an intentional engineering choice, justified only when the cost of product contamination, degradation, or unsafe storage is unacceptably high.

Making the Right Choice for Your Application

Selecting the correct cap is a function of your specific requirements for safety, purity, and cost.

- If your primary focus is sample purity and long-term storage: Choose PTFE lined caps for analytical standards, reagents, and pharmaceutical compounds to prevent chemical leaching and contamination.

- If your primary focus is handling aggressive chemicals: Use PTFE lined caps for storing acids, bases, and volatile organic solvents to ensure container integrity and user safety.

- If your application is general-purpose and non-reactive: A simpler, unlined cap is likely a more cost-effective and perfectly adequate solution.

Ultimately, selecting a PTFE lined cap is an investment in the integrity and safety of the material it protects.

Summary Table:

| Industry | Primary Use Case | Key Benefit of PTFE Liner |

|---|---|---|

| Pharmaceuticals & Biotechnology | Storing drug formulations & biological samples | Prevents leaching, ensures product integrity & safety |

| Laboratory & Analytical Chemistry | Preserving reagents & samples for accurate testing | Eliminates contamination, crucial for trace analysis |

| Chemical Processing | Sealing containers with corrosive acids & solvents | Provides robust chemical resistance, prevents leaks |

| Food & Beverage | Packaging acidic products like sauces & dressings | Non-stick, prevents flavor scalping, maintains freshness |

| Semiconductors | Storing ultra-pure chemicals for chip fabrication | Guarantees no contaminants from packaging |

| Petrochemical | Containing field samples of crude oil & chemicals | Resists corrosive media, wide temperature tolerance |

Need a PTFE lined cap that guarantees purity and safety for your application? KINTEK specializes in manufacturing high-precision PTFE components—including seals, liners, and labware—for semiconductor, medical, laboratory, and industrial industries. We offer custom fabrication from prototypes to high-volume orders, ensuring your materials are protected with unmatched chemical resistance. Contact us today to discuss your specific requirements and let our experts provide a tailored solution!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- Why are PTFE syringe filters indispensable? For Superior Chemical Resistance and Sample Integrity

- What are the temperature ranges for PTFE-lined bottle caps? From -200°C to +250°C for Your Critical Applications

- What are the main advantages of PTFE as a material for laboratory bottles? Superior Chemical & Thermal Resistance

- What are the safety features of PTFE-lined bottle caps? Ensure Chemical Inertness and Sample Integrity

- What are the key properties of PTFE syringe filters? Unlock Unmatched Chemical Resistance and Versatility

- Why is PTFE preferred over glass in certain labware applications? Achieve Superior Resilience for Harsh Conditions

- How do PTFE lined caps contribute to safety in laboratory testing? Prevent Leaks and Ensure Sample Integrity

- Why is PTFE particularly valuable in laboratory settings? Achieve Unmatched Purity and Safety