At its core, Polytetrafluoroethylene (PTFE) is exceptionally valuable in laboratory settings because of its extreme chemical inertness. Known commercially as Teflon, this material does not react with the vast majority of chemicals, including aggressive acids and solvents. This non-reactivity ensures that the equipment itself does not contaminate or alter the composition of sensitive samples, making it indispensable for experiments where purity and accuracy are paramount.

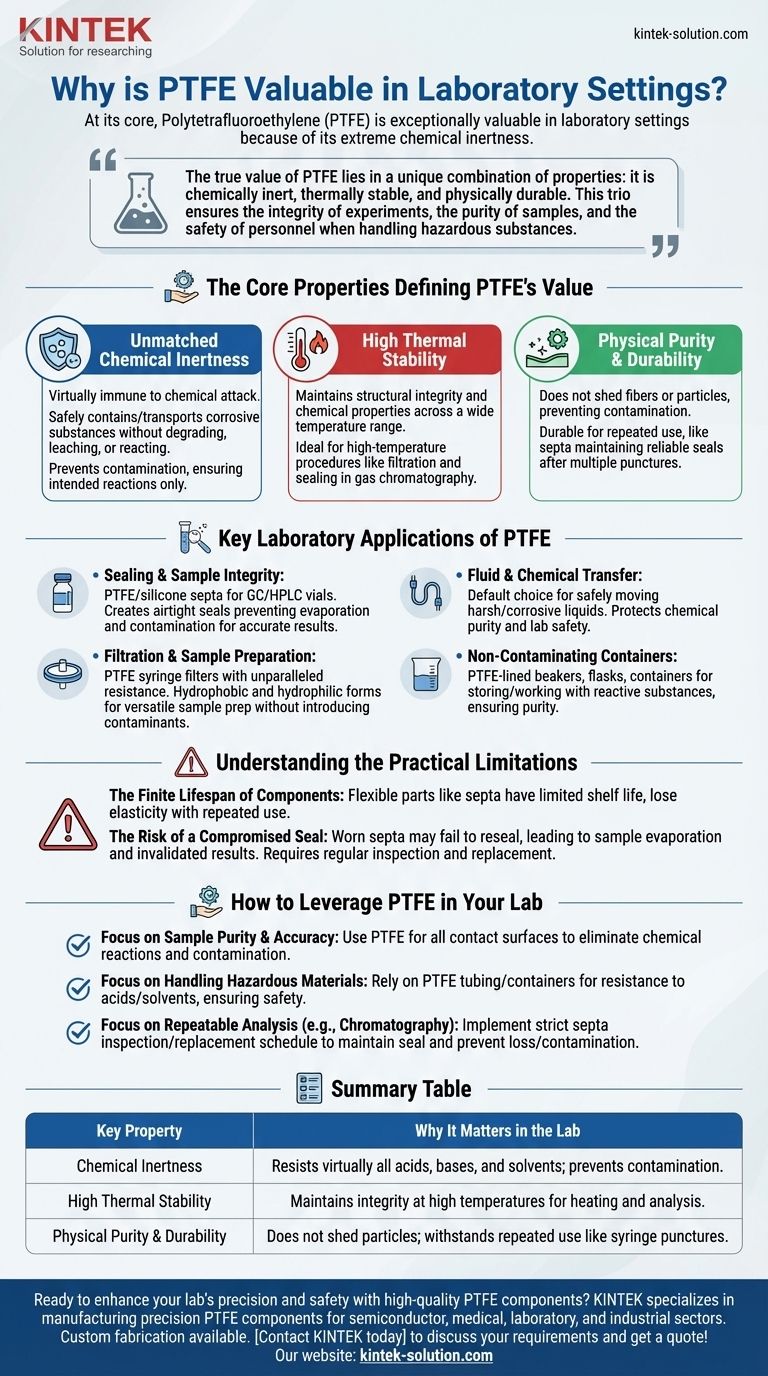

The true value of PTFE lies in a unique combination of properties: it is chemically inert, thermally stable, and physically durable. This trio ensures the integrity of experiments, the purity of samples, and the safety of personnel when handling hazardous substances.

The Core Properties Defining PTFE's Value

To understand PTFE's role, we must first examine the fundamental characteristics that set it apart from other materials. These properties directly address the most common challenges faced in a scientific lab.

Unmatched Chemical Inertness

PTFE is virtually immune to chemical attack. It can safely contain or transport highly corrosive substances without degrading, leaching, or reacting with the sample.

This property is critical for preventing contamination. When you use a PTFE beaker or tubing, you can be confident that the only reactions happening are the ones you intended.

High Thermal Stability

Many laboratory procedures require high temperatures. PTFE maintains its structural integrity and chemical properties across a wide temperature range where other plastics would melt or break down.

This makes it ideal for applications involving heat, from high-temperature filtration to sealing vials in a gas chromatograph's heated injection port.

Physical Purity and Durability

Unlike some materials, PTFE does not shed fibers or particles that could contaminate a sample. This is especially crucial in sensitive analytical techniques.

Furthermore, its durability allows for repeated use. Components like septa can withstand multiple punctures from a syringe needle while maintaining a reliable seal.

Key Laboratory Applications of PTFE

These core properties translate into specific, high-stakes applications where PTFE is the gold standard material. Its versatility allows it to be molded into many forms.

Sealing and Sample Integrity

PTFE/silicone septa are essential for sealing vials used in chromatography (GC and HPLC) and pharmaceutical research. They create an airtight seal that prevents sample evaporation and contamination.

This robust seal is critical for ensuring that experiment results are accurate and repeatable, especially when dealing with volatile organic compounds or valuable biologics.

Fluid and Chemical Transfer

PTFE tubing is the default choice for safely transferring harsh or corrosive liquids. Its inertness and durability make it perfect for moving acids, bases, and organic solvents without risk of the tubing breaking down.

This protects both the purity of the chemical being transferred and the safety of the lab environment.

Filtration and Sample Preparation

PTFE syringe filters offer unparalleled chemical resistance and can be used with virtually any solvent. They are available in both hydrophobic (resists water) and hydrophilic (attracts water) forms.

This versatility allows them to be used for a wide range of sample preparation needs, from clarifying aqueous solutions to filtering aggressive organic solvents, all without introducing contaminants.

Non-Contaminating Containers

For storing or working with highly reactive substances, PTFE-lined beakers, flasks, and containers are invaluable. They provide a completely non-reactive surface, ensuring the stored chemical remains pure over time.

Understanding the Practical Limitations

While incredibly useful, PTFE components are not without their operational considerations. Objectivity requires acknowledging their limits to ensure proper use.

The Finite Lifespan of Components

Flexible parts like PTFE/silicone septa have a limited shelf life. Over time and with repeated use, they can lose their elasticity and memory.

This degradation can compromise their sealing ability, leading to subtle but significant problems.

The Risk of a Compromised Seal

A worn-out septum may fail to reseal properly after being punctured by a syringe. This can lead to sample evaporation, which concentrates the sample and invalidates analytical results.

Therefore, regular inspection and scheduled replacement of these components are necessary to maintain optimal performance and data integrity.

How to Leverage PTFE in Your Lab

Your choice of material should be dictated by the specific demands of your work. Using PTFE correctly is key to reliable outcomes.

- If your primary focus is sample purity and accuracy: Use PTFE for all contact surfaces—containers, tubing, and filters—to eliminate the risk of chemical reactions and contamination.

- If your primary focus is handling hazardous materials: Rely on PTFE tubing and storage containers for their unmatched resistance to corrosive acids and aggressive solvents, ensuring a safer work environment.

- If your primary focus is repeatable analysis (e.g., chromatography): Implement a strict schedule for inspecting and replacing PTFE septa to maintain a perfect vial seal and prevent sample loss or contamination.

Ultimately, choosing a material as robust and inert as PTFE is a foundational step in generating trustworthy and reproducible scientific data.

Summary Table:

| Key Property | Why It Matters in the Lab |

|---|---|

| Chemical Inertness | Resists virtually all acids, bases, and solvents; prevents contamination. |

| High Thermal Stability | Maintains integrity at high temperatures for heating and analysis. |

| Physical Purity & Durability | Does not shed particles; withstands repeated use like syringe punctures. |

Ready to enhance your lab's precision and safety with high-quality PTFE components?

KINTEK specializes in manufacturing precision PTFE components—including seals, liners, labware, tubing, and custom parts—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your equipment maintains sample integrity and operates safely with aggressive chemicals.

We offer custom fabrication from prototypes to high-volume orders, tailored to your specific needs.

Contact KINTEB today to discuss your PTFE requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What industrial applications does PTFE have? Unlock Performance in Extreme Environments

- Why are PTFE vials considered environmentally friendly? Reduce Lab Waste with Durable Reusables

- Why is chemical compatibility important when choosing a PTFE-coated septum? Avoid Sample Contamination and Data Loss

- What are the primary applications of PTFE? Unlocking High-Performance Solutions

- What are the common characteristics of Teflon? Unlocking Extreme Chemical and Thermal Resistance