In laboratory settings, PTFE is preferred over glass for specific applications due to its superior combination of physical durability, extreme chemical inertness, and thermal stability. While glass is transparent and cost-effective, PTFE excels in harsh conditions where glass would break, crack from temperature changes, or be corroded by aggressive reagents.

The core decision between PTFE and glass is a trade-off. You choose glass for its transparency and general-purpose utility, but you choose PTFE for its exceptional resilience against chemical, thermal, and mechanical stress.

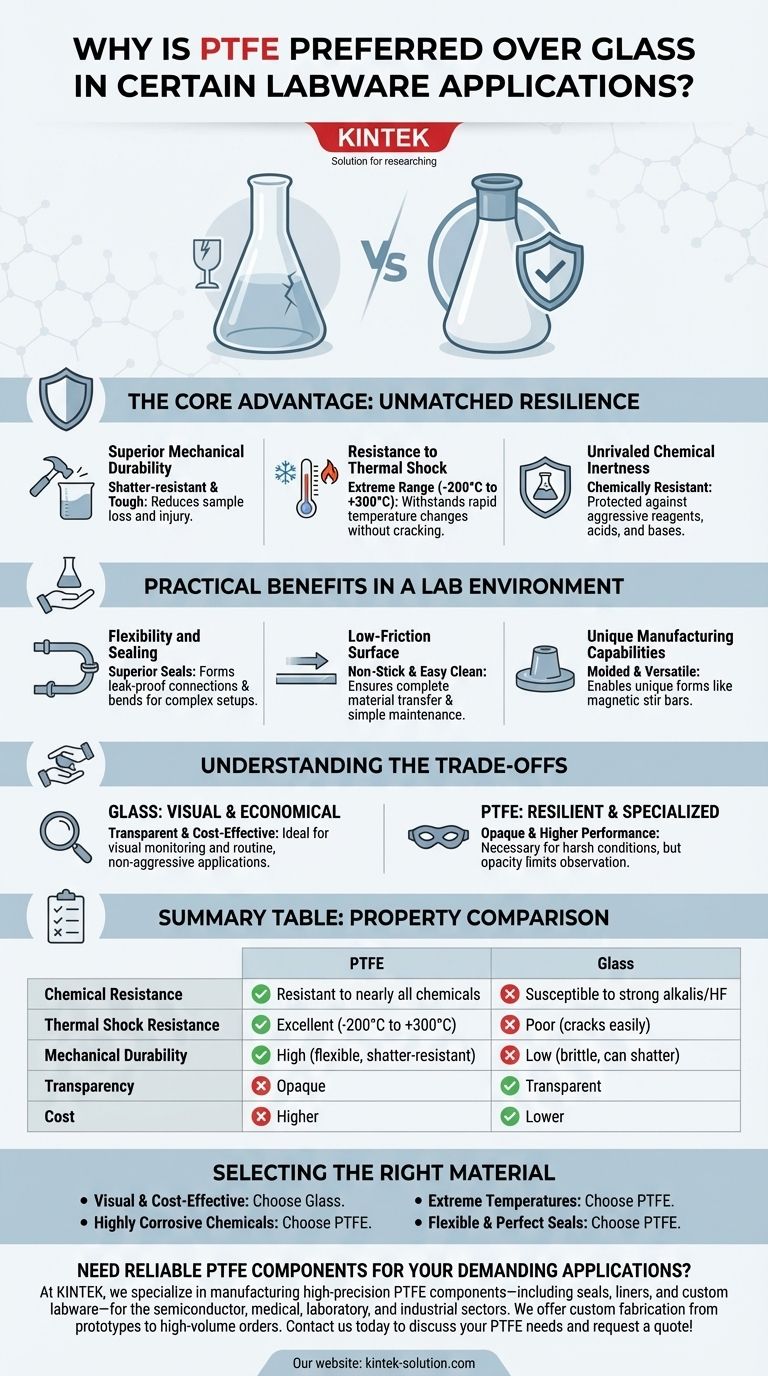

The Core Advantage: Unmatched Resilience

Glass is a fantastic general-purpose lab material, but it has well-known limits. PTFE was engineered to overcome these specific limitations, offering a level of resilience that glass cannot match.

Superior Mechanical Durability

PTFE labware does not easily break or shatter under load. This inherent toughness makes it a safer choice in busy environments, reducing the risk of sample loss and injury associated with broken glassware.

Resistance to Thermal Shock

A key weakness of glass is its susceptibility to cracking from rapid temperature changes. PTFE, by contrast, can withstand extreme temperature fluctuations across its vast operational range of -200°C to +300°C without risk of thermal shock.

Unrivaled Chemical Inertness

PTFE is famously resistant to nearly all chemicals, including the most aggressive acids and bases. This property comes from its unique molecular structure, where a helical carbon chain is completely sheathed by fluorine atoms, protecting the bonds from chemical attack.

Practical Benefits in a Lab Environment

Beyond its raw resilience, PTFE's physical properties provide distinct advantages for building and running experimental setups.

Flexibility and Sealing

Unlike rigid glass, PTFE is soft and flexible. This allows it to form superior, leak-proof seals in components like stopcocks and pipe fittings. It can also be bent to fit complex apparatus layouts where rigid glass tubing would be impractical.

Low-Friction Surface

PTFE has an extremely low coefficient of friction, which is why it's known commercially as Teflon. This non-stick quality is beneficial for containers and stirrers, ensuring complete transfer of materials and easy cleaning.

Unique Manufacturing Capabilities

PTFE's properties allow it to be used in ways glass cannot. A prime example is its ability to be molded around a magnetic core to create the chemically inert stir bars used in virtually every lab with a magnetic mixer.

Understanding the Trade-offs

Despite its advantages, PTFE is not a universal replacement for glass. Understanding its limitations is key to making an informed choice.

Opacity and Transparency

The most significant drawback of PTFE is that it is opaque. You cannot visually monitor reactions, titrations, or phase changes inside PTFE labware. Glass remains the undisputed choice when observation is critical.

Cost and General Use

Glass is significantly less expensive to manufacture than PTFE. For routine applications involving non-aggressive chemicals and moderate temperatures, the high performance of PTFE is unnecessary, making glass the more economical and practical option.

Structural Rigidity

While PTFE's flexibility is often an asset, the structural rigidity of glass is essential for building certain types of apparatus, such as complex distillation setups, that must maintain a precise and stable form.

Selecting the Right Material for Your Application

Your choice should always be dictated by the specific demands of your experiment.

- If your primary focus is visual monitoring and cost-effectiveness with standard reagents: Glass is the correct and most practical choice.

- If you are working with highly corrosive chemicals like strong acids or bases: PTFE's chemical inertness is essential for safety and sample purity.

- If your process involves extreme temperatures or rapid heating and cooling: PTFE's resistance to thermal shock prevents equipment failure.

- If you require flexible tubing or a perfect, chemically resistant seal: The softness and malleability of PTFE are ideal.

Ultimately, understanding the distinct strengths of both materials allows you to select the precise tool needed to ensure the success and safety of your work.

Summary Table:

| Property | PTFE | Glass |

|---|---|---|

| Chemical Resistance | Resistant to nearly all acids, bases, and solvents | Susceptible to corrosion by strong alkalis and hydrofluoric acid |

| Thermal Shock Resistance | Excellent (operates from -200°C to +300°C) | Poor (cracks under rapid temperature changes) |

| Mechanical Durability | High (flexible, shatter-resistant) | Low (brittle, can shatter) |

| Transparency | Opaque | Transparent |

| Cost | Higher | Lower |

Need reliable PTFE components for your demanding applications?

At KINTEK, we specialize in manufacturing high-precision PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your equipment performs safely and effectively, even in the most aggressive chemical and thermal environments.

We offer custom fabrication from prototypes to high-volume orders, tailored to your exact specifications. Let us help you enhance the safety and efficiency of your operations.

Contact us today to discuss your PTFE needs and request a quote!

Visual Guide

Related Products

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

People Also Ask

- What are the key properties of PTFE that make it suitable for chromatography septums? Ensure Sample Integrity and Reliable Results

- What are the key benefits of PTFE silicone septa in pharmaceutical research? Ensure Sample Integrity & Data Accuracy

- What temperature resistance do PTFE filters offer? Unmatched Thermal Stability from -200°C to +260°C

- Why is the combination of PTFE and silicone advantageous for chromatography septums? Achieve Unmatched Chemical Resistance and Durability

- What application-specific considerations should be taken into account when selecting a PTFE-coated septum? Ensure Analytical Integrity

- How does chemical compatibility of PTFE silicone septas benefit pharmaceutical research? Ensure Sample Integrity

- Why is PTFE used in laboratory applications? Ensure Chemical Purity and Reliability

- What role do sealing properties play in the effectiveness of PTFE/silicone septums? Ensure Sample Integrity and Data Accuracy