The primary safety features of PTFE-lined bottle caps are rooted in the material's fundamental properties. PTFE (Polytetrafluoroethylene) is exceptionally non-toxic and chemically inert, meaning it will not react with or leach into the substances it contains. This is reinforced by its high-temperature tolerance and ability to create a secure, physical seal, making it a trusted choice for sensitive laboratory, medical, and food-grade applications.

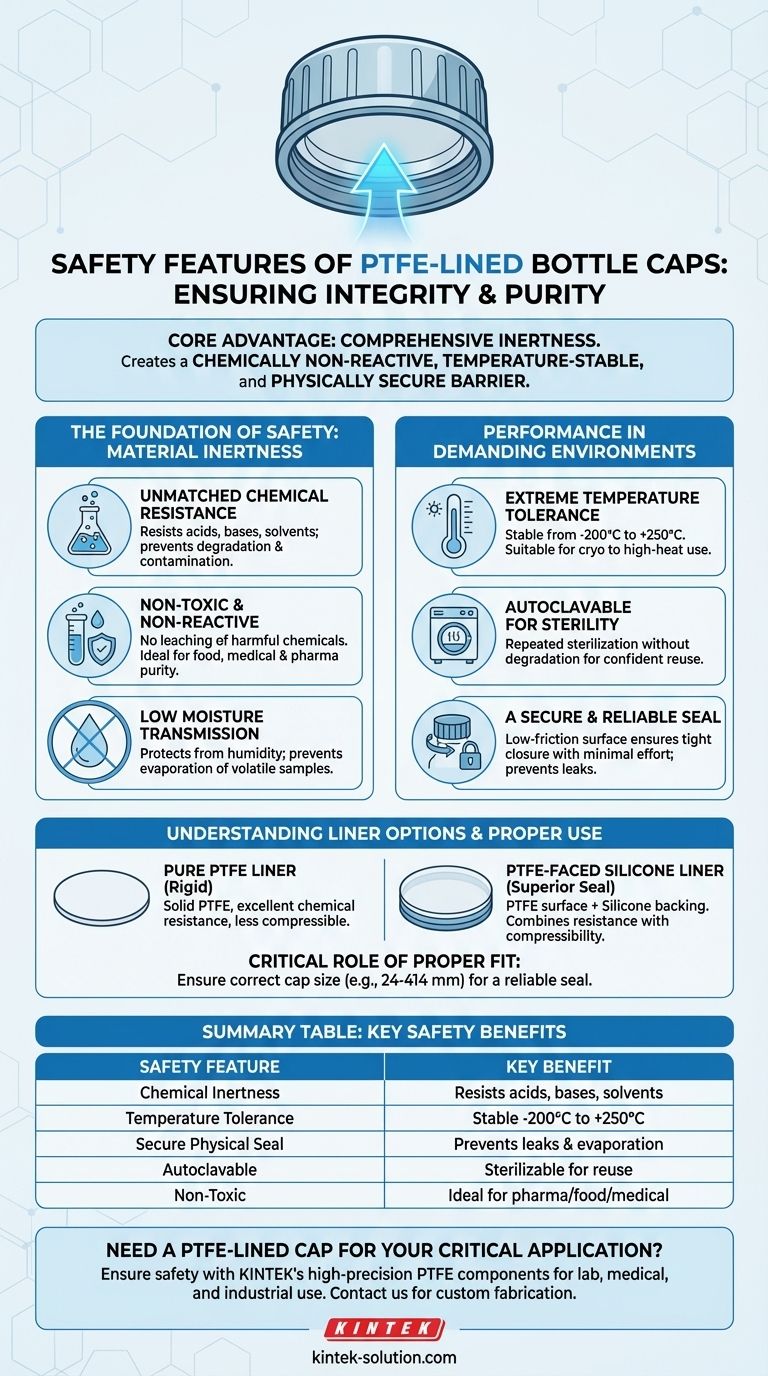

The core safety advantage of a PTFE liner is its comprehensive inertness. It creates a chemically non-reactive, temperature-stable, and physically secure barrier that protects the integrity of the stored contents from contamination or leakage.

The Foundation of Safety: Material Inertness

The reliability of a bottle cap begins with the material touching the contents. PTFE excels by creating a barrier that is almost universally non-reactive, ensuring the purity of the sample or product.

Unmatched Chemical Resistance

PTFE is highly resistant to a vast range of chemicals, including strong acids, bases, solvents, and other corrosive substances. This prevents the cap liner from degrading, dissolving, or reacting with the contents, which could otherwise lead to contamination or cap failure.

Non-Toxic and Non-Reactive

The material itself is non-toxic and will not leach harmful chemicals into the stored substance. This is a critical safety requirement for applications in the food, medical, and pharmaceutical industries, where sample purity is paramount.

Low Moisture Transmission

A key safety feature is the liner's ability to prevent moisture from entering or exiting the container. This protects sensitive contents from atmospheric humidity and prevents the evaporation of volatile samples.

Performance in Demanding Environments

Beyond chemical stability, a cap's safety is defined by how it performs under physical stress, such as extreme temperatures and repeated use.

Extreme Temperature Tolerance

PTFE liners maintain their integrity across an exceptionally wide temperature range, typically from -200°C to +250°C (-328°F to +482°F). This allows them to be used safely for everything from cryogenic storage to high-heat applications without becoming brittle or melting.

Autoclavable for Sterility

These caps can be repeatedly sterilized via autoclaving without degrading. This is a crucial safety feature in laboratory and medical settings, as it allows for confident reuse while eliminating the risk of cross-contamination.

A Secure and Reliable Seal

The low-friction, non-stick surface of PTFE allows the cap to be screwed on tightly with minimal effort, creating a secure seal that prevents leaks. This same property also ensures the cap can be opened easily without sticking or seizing.

Understanding Liner Options and Proper Use

While PTFE provides the core safety benefits, the construction of the liner and the fit of the cap are equally important for ensuring a reliable seal.

Pure PTFE vs. PTFE-Faced Liners

A solid PTFE liner is rigid. More commonly, caps use a PTFE-faced silicone liner. This construction combines the superior chemical resistance of a thin PTFE layer with the compressibility and elasticity of a silicone backing, creating a more resilient and airtight seal.

The Critical Role of Proper Fit

The most advanced liner is useless if the cap does not fit the container correctly. Using the right cap size, such as a common 24-414 mm thread, is essential for safety. An improper fit will compromise the seal and lead to leaks, regardless of the liner material.

Durability and Inspection

While highly durable and resistant to wear, PTFE liners are not indestructible. For applications involving repeated use, especially after autoclaving, a quick visual inspection for cracks or discoloration ensures the liner's integrity has not been compromised.

Making the Right Choice for Your Application

Selecting the correct cap is a critical safety decision. Your primary goal will determine the most important feature to focus on.

- If your primary focus is storing aggressive chemicals: The unmatched chemical inertness of the PTFE layer is your most critical safety feature.

- If your primary focus is high-purity lab samples: The non-toxic, non-leaching property of PTFE is essential to prevent contamination.

- If your primary focus is applications involving sterilization: The liner's ability to withstand repeated autoclaving without degrading ensures sterile, safe reuse.

- If your primary focus is preventing evaporation or leaks: Choose a PTFE-faced silicone liner for a superior, compressible seal.

By understanding these properties, you can confidently select a cap that ensures the integrity and safety of your most critical applications.

Summary Table:

| Safety Feature | Key Benefit |

|---|---|

| Chemical Inertness | Resists acids, bases, solvents; prevents contamination/leaching |

| Temperature Tolerance | Stable from -200°C to +250°C; suitable for cryogenic to high-heat use |

| Secure Physical Seal | Prevents leaks and evaporation; often PTFE-faced for compressibility |

| Autoclavable | Can be repeatedly sterilized without degrading for safe reuse |

| Non-Toxic | Ideal for pharmaceutical, food, and medical applications |

Need a PTFE-Lined Cap for Your Critical Application?

Ensure the safety and integrity of your sensitive samples, chemicals, or products. KINTEK specializes in manufacturing high-precision PTFE components, including seals, liners, and custom labware.

We serve the semiconductor, medical, laboratory, and industrial sectors, offering custom fabrication from prototypes to high-volume orders. Our commitment to precision production guarantees a reliable, chemically inert seal for your most demanding environments.

Contact KINTEK today to discuss your specific requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Bottles for Diverse Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance