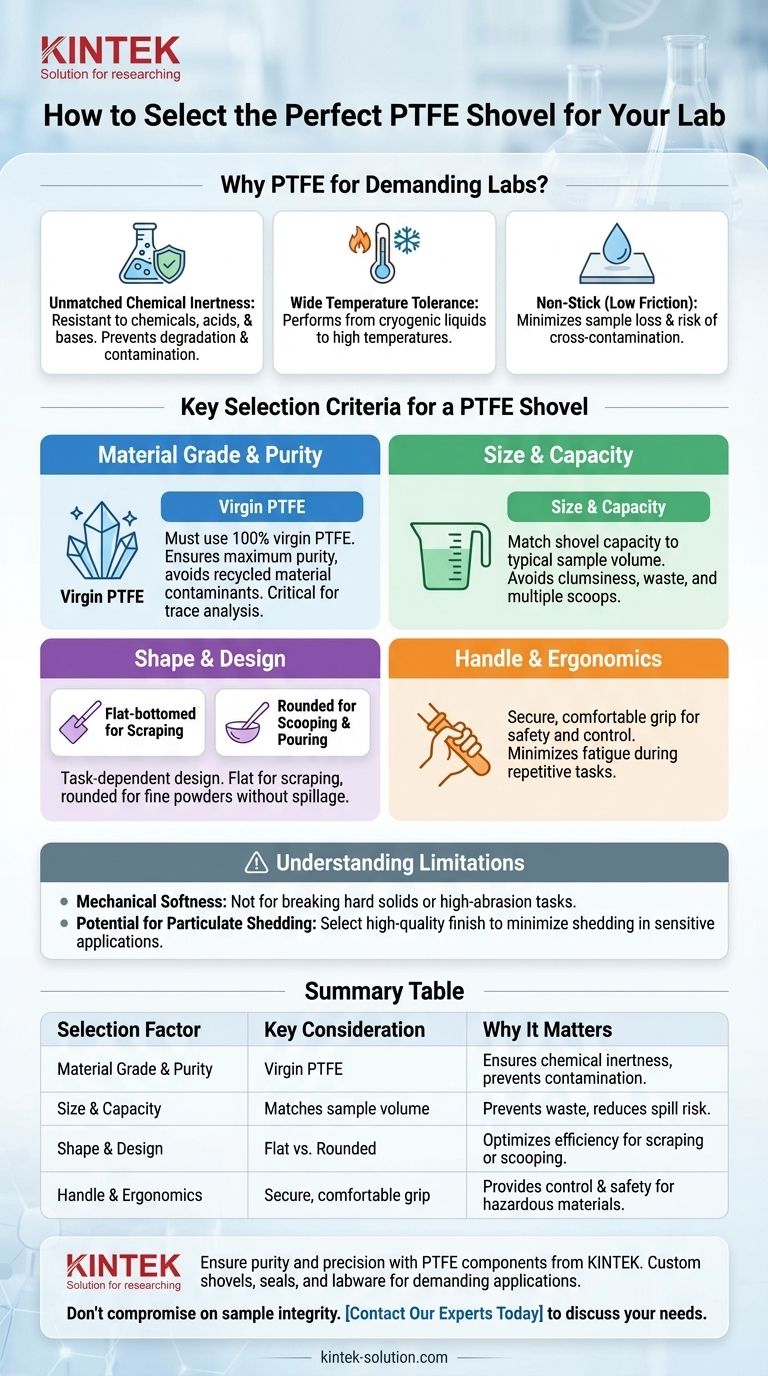

When selecting a PTFE shovel, you must evaluate four key factors: the size and capacity for your sample volume, the shape for the specific task (e.g., scraping vs. scooping), the handle design for safety and control, and most critically, the grade and purity of the PTFE material itself to ensure chemical compatibility and prevent contamination.

The ideal PTFE shovel is not just a tool for moving material; it's a piece of precision lab equipment. Your selection should be driven by the material's core properties—its chemical inertness and temperature resistance—matched directly to the demands of your specific laboratory application.

Why Choose PTFE in the First Place?

Before comparing specific shovels, it's essential to understand why PTFE (Polytetrafluoroethylene) is the material of choice for demanding lab environments. Its unique properties make it superior to standard plastic or metal for handling sensitive materials.

Unmatched Chemical Inertness

PTFE is famously resistant to nearly all chemicals, acids, and bases. This makes it the safest choice for handling aggressive or highly reactive substances without risk of the shovel degrading or leaching contaminants into your sample.

Wide Temperature Tolerance

This material maintains its integrity across an exceptionally broad temperature range. A high-quality PTFE shovel can be used for handling materials from cryogenic liquids up to high-temperature samples, a versatility that few other materials can offer.

Non-Stick (Low Friction) Surface

The low-friction surface of PTFE ensures that materials, especially sticky powders or viscous liquids, release easily. This minimizes sample loss and significantly reduces the risk of cross-contamination between uses.

Key Selection Criteria for a PTFE Shovel

With a clear understanding of the material's benefits, you can now focus on the physical attributes that differentiate one shovel from another.

Material Grade and Purity

Not all PTFE is created equal. For laboratory use, always seek out shovels made from virgin PTFE, which is free from recycled material. This ensures the highest level of chemical purity and performance, which is critical for trace analysis or high-purity work.

Size and Capacity

Consider the volume of material you typically handle. Using a shovel that is too large can be clumsy and wasteful, while one that is too small requires multiple scoops, increasing the risk of spills and exposure.

Shape and Design

The shape of the shovel head is task-dependent. A flat-bottomed design is ideal for scraping material from the bottom of a container, while a rounded, bowl-shaped design is better for scooping and pouring fine powders without spillage.

Handle and Ergonomics

A well-designed handle provides a secure, comfortable grip, which is a crucial safety feature when working with hazardous substances. Look for a design that allows for precise control and minimizes hand fatigue during repetitive tasks.

Understanding the Limitations

While PTFE is an exceptional material, it's important to be aware of its trade-offs to use it effectively and safely.

Mechanical Softness

PTFE is a relatively soft material. It is not designed for breaking up hard, caked solids or for high-abrasion tasks. Using it for such purposes can damage the shovel and potentially introduce PTFE particles into your sample.

Potential for Particulate Shedding

Because it is a soft polymer, low-quality or poorly machined PTFE can shed micro-particles. For applications where particulate contamination is a major concern, select a shovel with a very smooth, high-quality surface finish from a reputable labware manufacturer.

Making the Right Choice for Your Task

Your final decision should be a direct reflection of your primary lab work.

- If your primary focus is handling aggressive chemicals: Prioritize a shovel explicitly certified as being made from 100% virgin PTFE.

- If your primary focus is working with valuable or fine powders: Choose a design with a highly polished, non-stick surface and a shape that minimizes spillage.

- If your primary focus is working across a wide temperature range: Verify the manufacturer's specified operating temperature limits to ensure safety and performance.

Selecting the correct PTFE shovel is a direct investment in the safety, accuracy, and integrity of your work.

Summary Table:

| Selection Factor | Key Consideration | Why It Matters |

|---|---|---|

| Material Grade & Purity | Virgin PTFE (vs. recycled) | Ensures maximum chemical inertness and prevents sample contamination. |

| Size & Capacity | Matches typical sample volume | Prevents waste and reduces spill risk from using an improperly sized tool. |

| Shape & Design | Flat-bottomed (scraping) vs. Rounded (scooping) | Optimizes efficiency for specific tasks like transferring powders or scraping containers. |

| Handle & Ergonomics | Secure, comfortable grip | Provides control and safety when handling hazardous or sensitive materials. |

Ensure the purity and precision of your laboratory work with PTFE components from KINTEK.

Selecting the right tool is critical. At KINTEK, we specialize in manufacturing high-purity PTFE components—including custom shovels, seals, liners, and labware—for the most demanding applications in the semiconductor, medical, laboratory, and industrial sectors.

We prioritize precision production and use only the highest-grade materials to guarantee chemical inertness, temperature resistance, and a superior non-stick surface. Whether you need a standard item or a custom-fabricated solution from prototype to high-volume order, we are here to support your specific requirements.

Don't compromise on sample integrity. Contact our experts today to discuss your PTFE component needs and request a quote.

Visual Guide

Related Products

- Customizable PTFE Scrapers and Shovels for Demanding Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- PTFE Chemical Solvent Sampling Spoon

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What does PTFE stand for? The Science Behind the Super-Material

- Why is PTFE considered ideal for use in the food and beverage industry? Ensure Safety & Efficiency

- What is PTFE and what are its common uses? A Guide to the High-Performance Polymer

- Which industries commonly use PTFE materials? A Guide to High-Performance Polymer Applications

- Why are PTFE shovels considered cost-effective? Maximize ROI with Superior Durability