In short, Polytetrafluoroethylene (PTFE) is a high-performance synthetic plastic, a fluoropolymer most famously known by the brand name Teflon. While recognized for creating non-stick surfaces on cookware, its true value lies in a unique combination of properties—including extreme chemical resistance, high-temperature tolerance, and exceptionally low friction—making it a critical material in industries from aerospace to medicine.

The key takeaway is not that PTFE is simply a non-stick coating, but that it is a versatile "problem-solver" material. Its value comes from a rare combination of properties that allows it to perform in harsh environments where most other materials would fail.

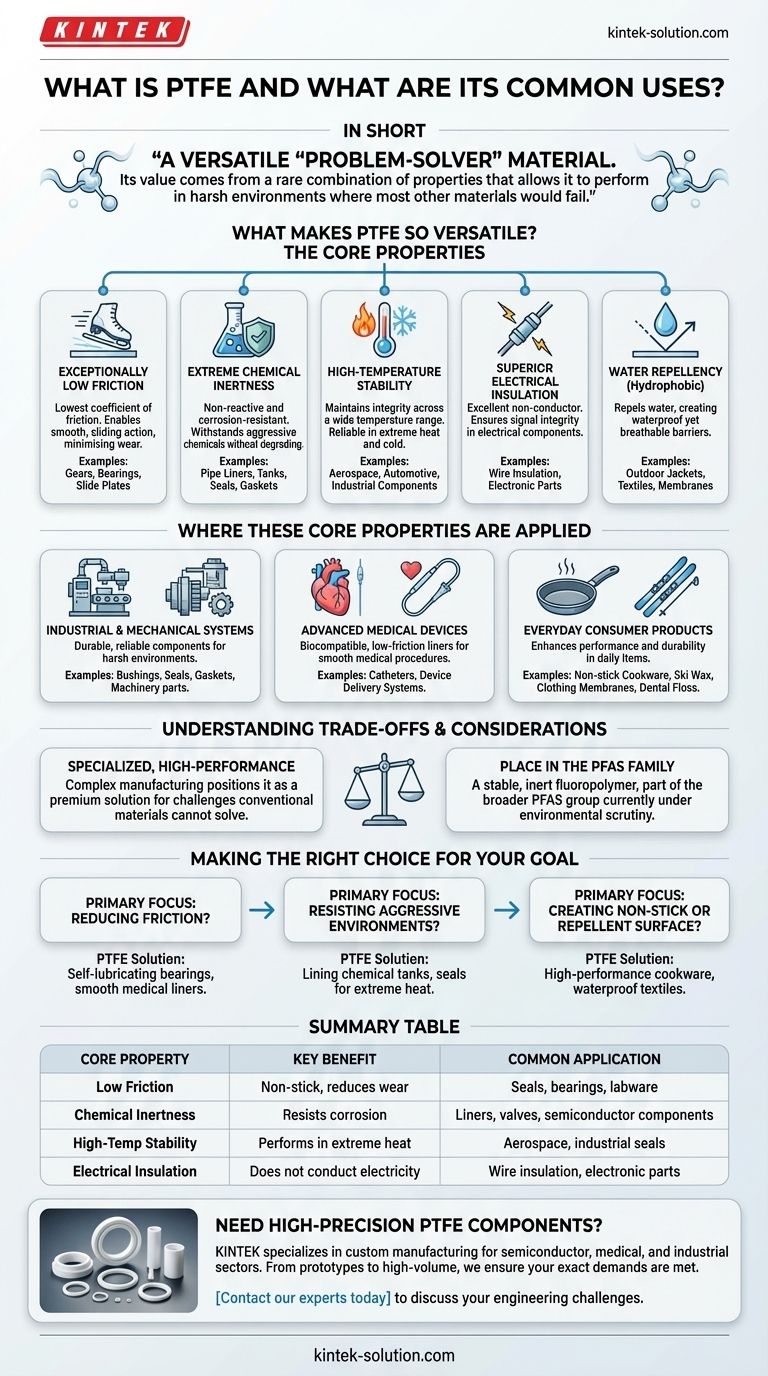

What Makes PTFE So Versatile? The Core Properties

The widespread use of PTFE is not due to a single feature, but to a powerful synergy of several distinct characteristics. Understanding these core properties explains why it appears in so many unrelated applications.

Exceptionally Low Friction

PTFE has one of the lowest coefficients of friction of any known solid material. This "slipperiness" is what provides the non-stick quality in pans.

In industrial settings, this property is critical for components that require smooth, sliding action with minimal wear, such as gears, bearings, and slide plates.

Extreme Chemical Inertness

This material is non-reactive and corrosion-resistant, meaning it can withstand exposure to the vast majority of aggressive chemicals without degrading.

This makes it an ideal choice for lining pipes, tanks, valves, and creating seals or gaskets in chemical processing plants where corrosive substances are common.

High-Temperature Stability

PTFE can maintain its integrity and properties across an incredibly wide temperature range. It performs reliably in both extremely high and low-temperature environments.

This thermal resistance is crucial for applications in aerospace, automotive, and demanding industrial processes where components are exposed to extreme heat.

Superior Electrical Insulation

PTFE is an excellent electrical insulator, meaning it does not conduct electricity. This makes it a valuable material for insulating wires and manufacturing electrical components where signal integrity is essential.

Water Repellency

PTFE is hydrophobic, meaning it repels water. This property is leveraged to create waterproof yet breathable membranes in high-performance outdoor jackets and textiles.

Where These Core Properties Are Applied

The unique combination of these traits allows PTFE to solve challenges across a diverse range of fields, from heavy industry to delicate medical procedures.

In Industrial and Mechanical Systems

The backbone of modern industry relies on materials that are durable and reliable. Here, PTFE's heat resistance and chemical inertness are paramount.

It is machined into durable parts like bushings, seals, and gaskets that ensure machinery runs efficiently and safely, especially in harsh chemical or high-temperature environments.

In Advanced Medical Devices

In healthcare, materials must be both effective and safe for human tissue. PTFE is biocompatible and its low-friction surface is invaluable.

It is frequently used as a liner for catheters and other device delivery systems. This ensures medical tools can be inserted and maneuvered smoothly, minimizing tissue damage.

In Everyday Consumer Products

Many people interact with PTFE daily without realizing its full scope. Its properties make everyday products better and more durable.

Beyond non-stick cookware, it is found in ski wax for better glide, as a water-repellent membrane in clothing, and even in some types of dental floss.

Understanding the Trade-offs and Considerations

No material is perfect for every situation. Being a trusted advisor means acknowledging a material's full context, including its complexities and surrounding discussions.

A Specialized, High-Performance Material

PTFE is not a simple commodity plastic. Its manufacturing process is complex, which positions it as a higher-performance, and often higher-cost, solution for problems that conventional materials cannot solve.

Its Place in the PFAS Family

PTFE is a type of fluorinated polymer, which belongs to the broader group of chemicals known as PFAS (per- and polyfluoroalkyl substances).

While PTFE itself is a stable, non-toxic, and inert polymer under normal use conditions, the wider PFAS category is under scrutiny for environmental persistence and potential health concerns associated with some specific compounds used in their manufacturing.

Making the Right Choice for Your Goal

Understanding PTFE's core strengths allows you to recognize why it is chosen for a specific task. Its application is almost always a direct solution to a challenging engineering problem.

- If your primary focus is reducing friction: PTFE is chosen for applications like self-lubricating bearings or smooth medical catheter liners.

- If your primary focus is resisting aggressive environments: PTFE is the solution for lining chemical tanks or creating seals that must withstand extreme heat.

- If your primary focus is creating a non-stick or repellent surface: PTFE is the established technology for everything from high-performance cookware to waterproof textiles.

Ultimately, Polytetrafluoroethylene is a testament to how advanced material science provides solutions to some of the most difficult engineering challenges across every major industry.

Summary Table:

| Core Property | Key Benefit | Common Application |

|---|---|---|

| Low Friction | Non-stick, reduces wear | Seals, bearings, labware |

| Chemical Inertness | Resists corrosion | Liners, valves, semiconductor components |

| High-Temp Stability | Performs in extreme heat | Aerospace, industrial seals |

| Electrical Insulation | Does not conduct electricity | Wire insulation, electronic parts |

Need high-precision PTFE components for your project?

KINTEK specializes in manufacturing custom PTFE seals, liners, and labware for the semiconductor, medical, and industrial sectors. We combine precision production with the ability to scale from prototypes to high-volume orders, ensuring your components meet the exact demands of your application.

Contact our experts today to discuss how our PTFE solutions can solve your specific engineering challenges.

Visual Guide

Related Products

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- PTFE Chemical Solvent Sampling Spoon

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- What are the common characteristics of Teflon? Unlocking Extreme Chemical and Thermal Resistance

- What makes the PTFE bottle durable? Unmatched Chemical & Thermal Stability for Demanding Applications

- What are some exceptional properties of PTFE? Unlock Unmatched Performance in Extreme Environments

- In which industries is PTFE commonly used? Key Applications for Chemical & Thermal Resistance

- What material is the PTFE bottle made from? Discover the Benefits of 100% Virgin PTFE