In short, a PTFE bottle's remarkable durability stems from its fundamental molecular structure, which makes it almost completely resistant to chemical attack, temperature extremes, and environmental degradation. This isn't just about being tough; it's about being chemically and physically stable in conditions that would destroy most other materials.

A PTFE bottle is durable not because it is rigid like glass or metal, but because it is profoundly non-reactive. Its longevity comes from its ability to ignore chemical, thermal, and environmental stressors that cause other materials to corrode, melt, or become brittle.

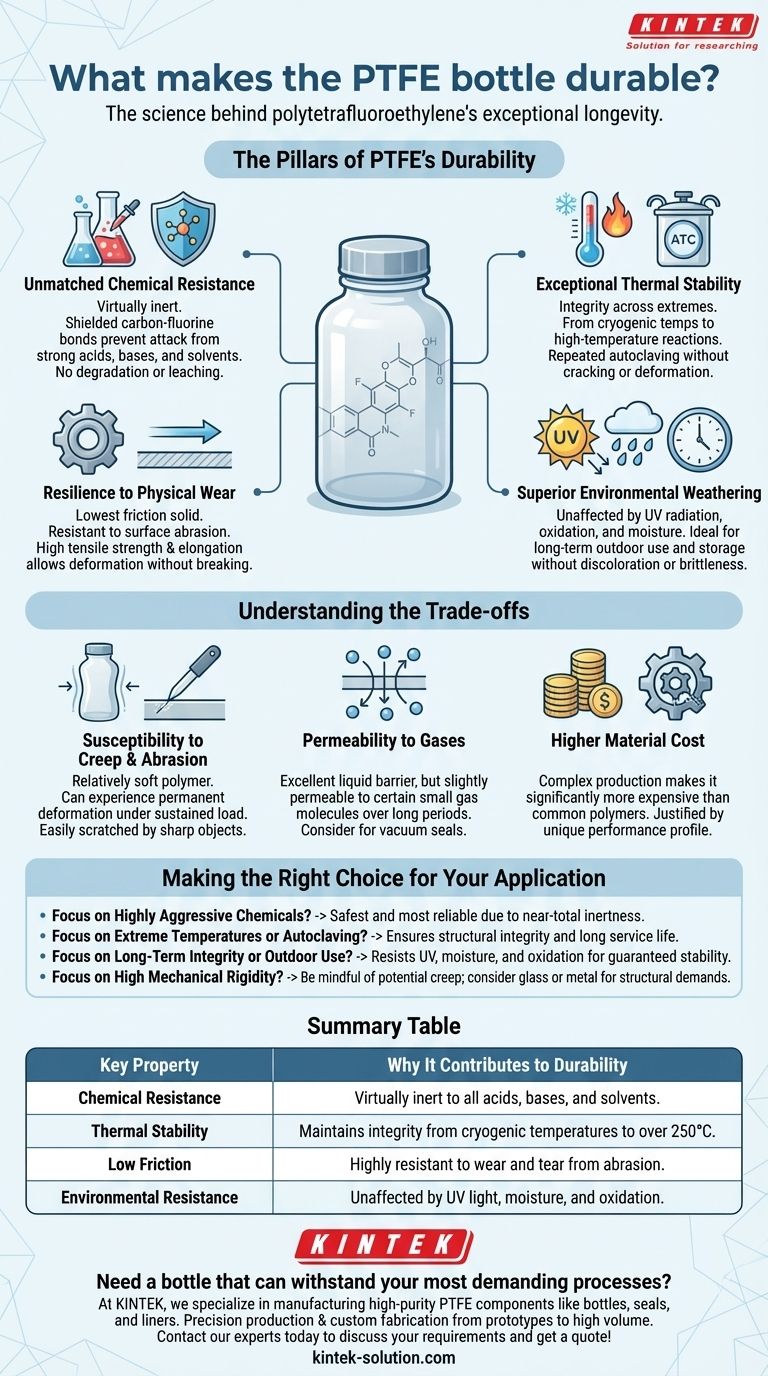

The Pillars of PTFE's Durability

The durability of Polytetrafluoroethylene (PTFE) is not a single feature but the result of several distinct properties working in concert. Understanding these pillars is key to knowing when and why to trust this material.

Unmatched Chemical Resistance

PTFE is virtually inert and impervious to attack from nearly all chemicals, including the most aggressive acids, bases, and solvents.

This unique property arises from the strong carbon-fluorine bonds that shield the molecule's carbon backbone, preventing chemical agents from finding a point of attack. This ensures the bottle's structure will not degrade or leach impurities into its contents.

Exceptional Thermal Stability

PTFE maintains its integrity across an exceptionally wide range of temperatures. It has a high melting point and does not become brittle at cryogenic temperatures.

This allows PTFE bottles to be used for high-temperature reactions or to be repeatedly sterilized via autoclaving without any degradation, cracking, or loss of shape.

Resilience to Physical Wear

While not exceptionally hard, PTFE is highly resistant to wear and tear due to its very low coefficient of friction—the lowest of any known solid material.

This "slipperiness" means surfaces are less likely to abrade or wear down over time. It also exhibits high tensile strength (280-350 kg/cm²) and elongation (200-400%), allowing it to deform without breaking.

Superior Environmental Weathering

PTFE is highly resistant to environmental factors that degrade other polymers, such as UV radiation, oxidation, and moisture.

A PTFE bottle can be used outdoors or stored for years without discoloring, weakening, or becoming brittle. Its low water absorption and low permeability further enhance its long-term stability.

Understanding the Trade-offs

No material is perfect. While incredibly durable in specific contexts, PTFE's unique properties come with practical limitations that are crucial to understand.

Susceptibility to Creep and Abrasion

PTFE is a relatively soft polymer. Under a sustained mechanical load, it can be subject to "creep," a slow, permanent deformation.

While resistant to wear from friction, it can be easily scratched or scored by sharp, hard materials. Its durability is chemical and thermal, not necessarily mechanical in the way metal is.

Permeability to Gases

While excellent at repelling liquids, PTFE is slightly permeable to certain small gas molecules over long periods.

For long-term storage of sensitive gases or applications requiring a perfect vacuum seal, this slight permeability may be a critical factor to consider.

Higher Material Cost

The complex process required to manufacture and form PTFE makes it significantly more expensive than common polymers like polypropylene or polyethylene.

This cost is justified by its unique performance profile, but it makes it unsuitable for applications where a less robust, more economical material would suffice.

Making the Right Choice for Your Application

To determine if a PTFE bottle is the right choice, align its specific strengths with the primary demands of your task.

- If your primary focus is containing highly aggressive chemicals: PTFE's near-total chemical inertness makes it the safest and most reliable choice.

- If your primary focus is applications with extreme temperatures or repeated autoclaving: Its thermal stability ensures structural integrity and a long service life where other plastics would fail.

- If your primary focus is long-term sample integrity or outdoor use: Its resistance to UV, moisture, and oxidation guarantees it will not degrade or contaminate your contents over time.

- If your primary focus is high mechanical rigidity under constant pressure: Be mindful of PTFE's potential to creep and consider a different material like glass or metal for structural applications.

Ultimately, choosing a PTFE bottle is an investment in unparalleled chemical and thermal stability for your most critical applications.

Summary Table:

| Key Property | Why It Contributes to Durability |

|---|---|

| Chemical Resistance | Virtually inert to all acids, bases, and solvents. |

| Thermal Stability | Maintains integrity from cryogenic temperatures to over 250°C. |

| Low Friction | Highly resistant to wear and tear from abrasion. |

| Environmental Resistance | Unaffected by UV light, moisture, and oxidation. |

Need a bottle that can withstand your most demanding processes?

At KINTEK, we specialize in manufacturing high-purity PTFE components like bottles, seals, and liners. Our expertise ensures precision production and custom fabrication—from prototypes to high-volume orders—for the semiconductor, medical, laboratory, and industrial sectors.

Invest in the unmatched durability of a PTFE bottle designed for your specific application. Contact our experts today to discuss your requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

People Also Ask

- How do PTFE/silicone septa maintain sample integrity in HPLC autosampler vials? Ensuring Accurate and Reliable Results

- What types of equipment are PTFE ferromagnetic support discs compatible with? Boost Your Lab's Efficiency

- What are some specialized PTFE stirring bars available? Optimize Your Lab Mixing Efficiency

- How should PTFE shovels be cleaned and stored? Protect Your Investment with Proper Care

- What are the advantages of using PTFE stirrers and shafts in corrosive applications? Ensure Purity and Reliability

- Why are PTFE filters advantageous for gravimetric analysis? Achieve Unmatched Accuracy and Precision

- What role do sealing properties play in the effectiveness of PTFE/silicone septums? Ensure Sample Integrity and Data Accuracy

- What makes PTFE-lined caps important? Ensure Sample Purity and Safety in Your Lab