Polytetrafluoroethylene (PTFE) is considered ideal for the food and beverage industry because its unique combination of properties—chemical inertness, high-temperature stability, and a non-stick surface—directly addresses the industry's most critical requirements for safety, hygiene, and operational efficiency. This makes it a trusted material for everything from non-stick cookware to essential seals in processing equipment.

The true value of PTFE in food applications goes beyond its famous non-stick quality. Its fundamental inability to react with food products is the bedrock of its food-safe status, ensuring that nothing leaches into the product, regardless of temperature or acidity.

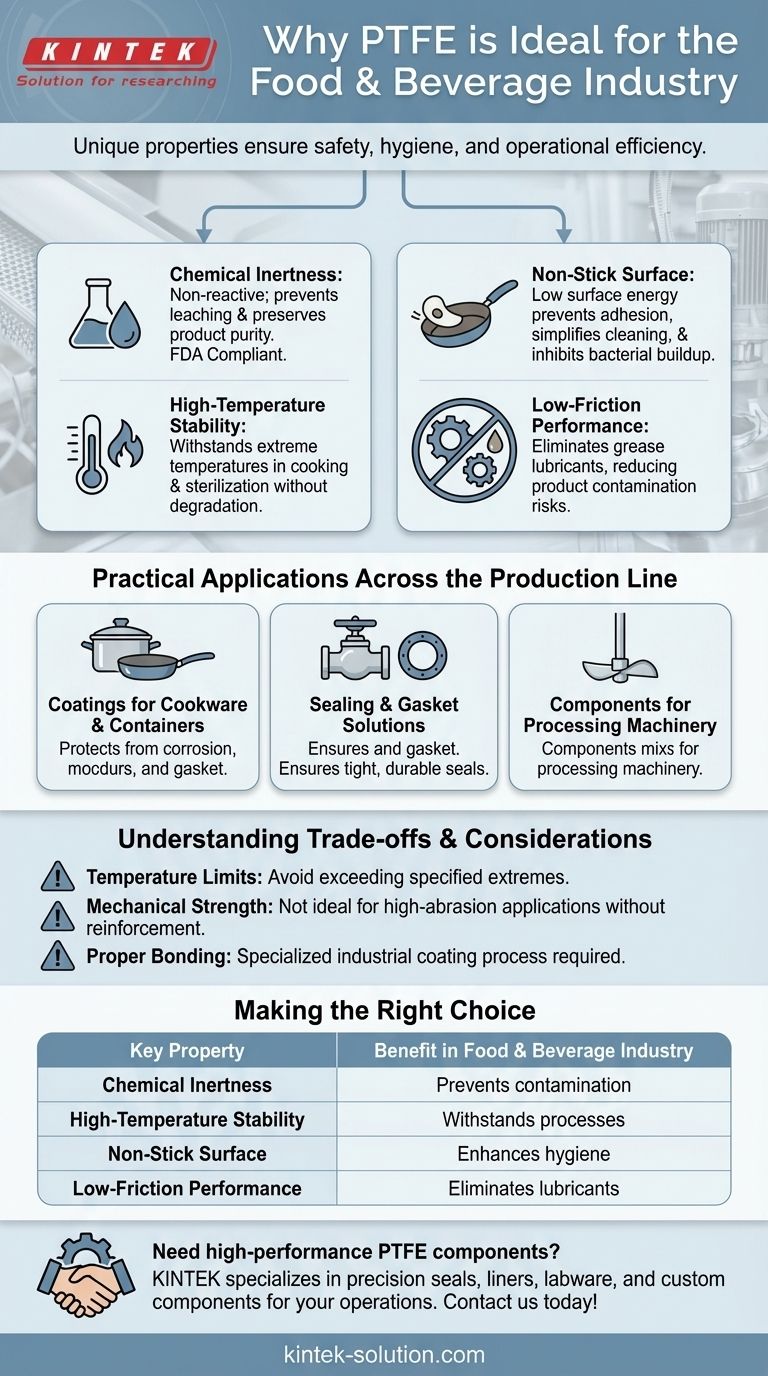

The Core Properties That Define PTFE's Role

To understand why PTFE is so prevalent, we must look at its specific material characteristics. These properties solve fundamental challenges in food processing and handling.

Chemical Inertness: The Foundation of Food Safety

PTFE is exceptionally non-reactive. It does not react with acidic ingredients, oxidizing agents, or other aggressive substances commonly found in food and beverages.

This chemical stability is crucial because it prevents the material from leaching contaminants into the food, thereby preserving the product's purity and taste. Materials like PTFE that meet FDA standards are certified as safe for direct food contact.

High-Temperature Stability: Reliability Under Pressure

The food industry relies on processes that involve extreme temperatures, from cooking and baking to sterilization.

PTFE can withstand consistent use at high temperatures without degrading, a quality that makes it more durable than many alternative materials. This ensures reliability and safety in demanding applications like cookware and heat exchangers.

Non-Stick Surface: The Key to Hygiene and Efficiency

PTFE's low surface energy gives it its well-known non-stick, or hydrophobic, quality. This prevents food particles from adhering to equipment surfaces.

This property is vital for hygiene, as it simplifies cleaning and prevents the buildup of deposits that can harbor bacteria. In processing equipment, this reduces downtime and maintains operational efficiency.

Low-Friction Performance: Eliminating Contaminants

In mechanical applications, PTFE provides a low-friction surface that often eliminates the need for traditional lubricants like grease.

This is a significant advantage in equipment such as mixers or non-metal bearings. By removing the need for grease, you remove a potential source of product contamination, ensuring a cleaner process.

Practical Applications Across the Production Line

These core properties translate directly into a wide range of uses, demonstrating PTFE's versatility.

Coatings for Cookware and Containers

The most familiar application is non-stick coatings on pots and pans. PTFE is also used to line the interior of food and beverage containers, protecting the contents from corrosion and contamination.

Sealing and Gasket Solutions

PTFE gaskets and seals are critical components in pumps, valves, pressure vessels, and heat exchangers. Their chemical and heat resistance ensures a tight, durable seal that prevents leaks and protects product integrity.

Components for Processing Machinery

Within food processing machinery, PTFE is used for rotary shaft seals, mixer components, and pipe liners. Its non-stick nature prevents buildup on equipment surfaces, which is essential for maintaining consistent flow and efficiency in bottling and processing lines.

Understanding the Trade-offs and Considerations

While PTFE is highly effective, no material is perfect for every scenario. Acknowledging its limitations is key to using it correctly.

Temperature Limits and Degradation

While PTFE has excellent high-temperature tolerance, it is not infinite. At extremely high temperatures (well above normal cooking and processing ranges), it can begin to degrade. It's essential to operate within the material's specified temperature limits.

Mechanical Strength and Abrasion

PTFE is a relatively soft material. In applications with high mechanical stress or significant abrasive forces, pure PTFE might not be the most durable option without reinforcement (e.g., filled PTFE grades).

Proper Application and Bonding

The same non-stick quality that makes PTFE valuable also makes it difficult to bond to other surfaces. Applying PTFE coatings is a specialized industrial process that must be done correctly to ensure durability and performance.

Making the Right Choice for Your Goal

Selecting the right material depends entirely on the specific demands of your application.

- If your primary focus is direct food contact and hygiene: PTFE's non-stick surface and FDA-compliant, non-reactive nature make it the default choice for coatings, liners, and seals.

- If your primary focus is mechanical efficiency without contamination: Its low-friction properties are ideal for bearings and mixer components where lubricating grease is not an option.

- If your primary focus is long-term durability in harsh environments: PTFE's resistance to both high heat and corrosive food ingredients ensures equipment longevity and reliability.

Ultimately, PTFE's value in the food industry is rooted in its fundamental stability and its inability to interact with the products it touches.

Summary Table:

| Key Property | Benefit in Food & Beverage Industry |

|---|---|

| Chemical Inertness | Prevents contamination, ensures product purity and FDA compliance |

| High-Temperature Stability | Withstands cooking, baking, and sterilization processes |

| Non-Stick Surface | Enhances hygiene, simplifies cleaning, prevents bacterial buildup |

| Low-Friction Performance | Eliminates need for lubricants, reducing contamination risk |

Need high-performance PTFE components for your food and beverage operations?

At KINTEK, we specialize in manufacturing precision PTFE seals, liners, labware, and custom components for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures you get reliable, food-safe solutions that enhance safety and efficiency.

Contact us today to discuss your specific requirements and discover how our PTFE solutions can benefit your application!

Visual Guide

Related Products

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- PTFE Chemical Solvent Sampling Spoon

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the unique properties of PTFE that make it commercially valuable? Unlock Unmatched Performance

- What makes the PTFE bottle durable? Unmatched Chemical & Thermal Stability for Demanding Applications

- In which industries is PTFE commonly used? Key Applications for Chemical & Thermal Resistance

- What are some exceptional properties of PTFE? Unlock Unmatched Performance in Extreme Environments

- Why are PTFE vials considered environmentally friendly? Reduce Lab Waste with Durable Reusables