The cost-effectiveness of PTFE shovels is not about their initial price, but their total cost of ownership. Their exceptional durability and resistance to wear mean they last significantly longer than alternatives, drastically reducing the frequency and cost of replacements over time.

The financial case for PTFE components rests on a simple principle: a higher upfront investment in a material's superior resilience pays dividends by minimizing the recurring costs of replacement, maintenance, and operational downtime.

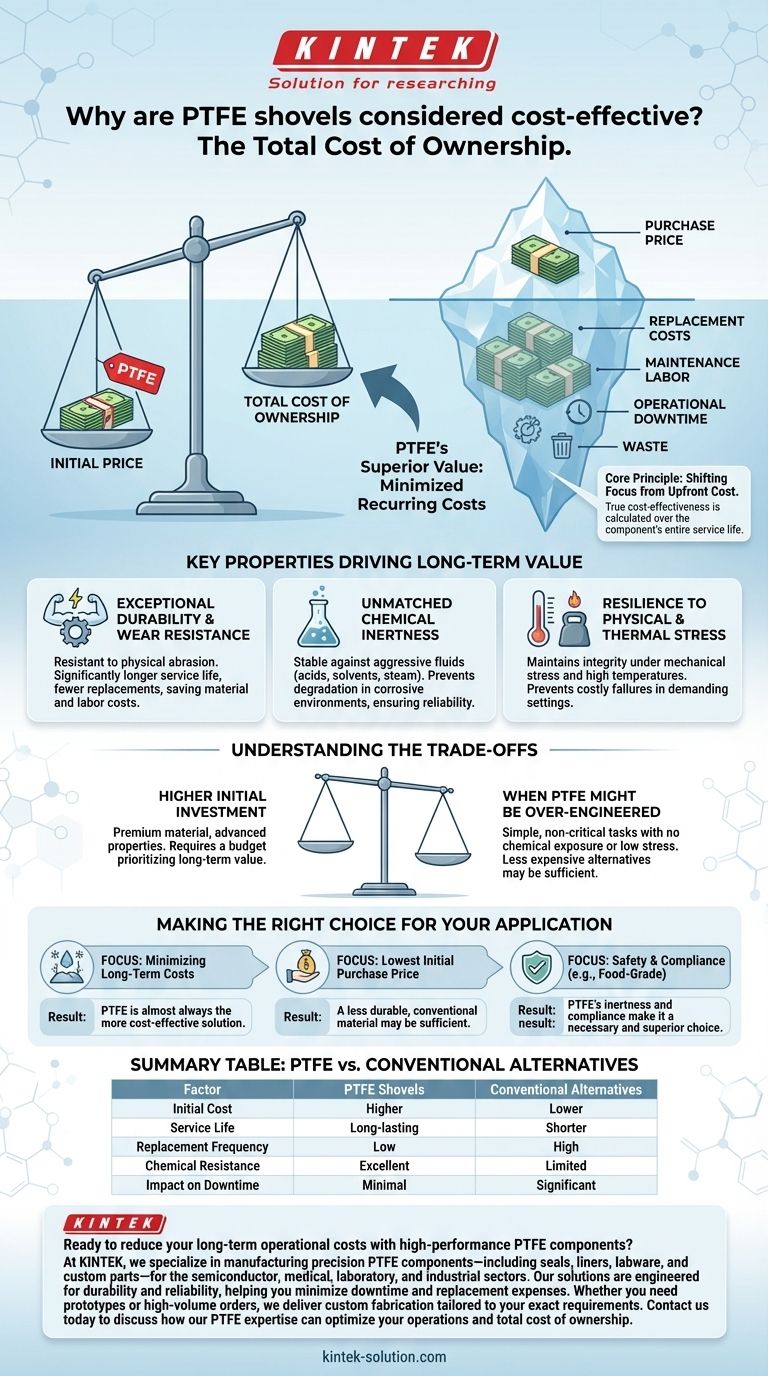

The Core Principle: Total Cost of Ownership vs. Purchase Price

Shifting Focus from Upfront Cost

Components made from Polytetrafluoroethylene (PTFE), from shovels to industrial gaskets, often carry a higher initial purchase price compared to conventional materials.

Focusing solely on this sticker price provides an incomplete financial picture and often leads to poor long-term decisions.

Factoring in Long-Term Operational Expenses

True cost-effectiveness is calculated over the component's entire service life.

This includes not just the price of replacement parts, but also the labor for installation and the significant financial impact of operational downtime during maintenance.

Key Properties Driving Long-Term Value

Exceptional Durability and Wear Resistance

PTFE is inherently resistant to the physical abrasion and wear that degrades other materials.

This long service life is the primary reason it requires fewer replacements, directly saving on both material and labor costs over the long run.

Unmatched Chemical Inertness

The material is remarkably stable when exposed to a wide range of aggressive fluids, including hydrocarbons, acids, solvents, and steam.

This chemical resistance prevents the degradation that would quickly destroy lesser materials, ensuring reliability in corrosive environments.

Resilience to Physical and Thermal Stress

PTFE components are engineered to maintain their integrity under significant mechanical stress and in high-temperature environments.

This reliability is crucial in demanding industrial settings where unexpected component failure can lead to costly and dangerous situations.

Understanding the Trade-offs

The Higher Initial Investment

The most significant trade-off is the upfront cost. PTFE is a premium material, and its initial price reflects its advanced properties and manufacturing process.

This requires a budget that prioritizes long-term value and operational stability over immediate, short-term savings.

When PTFE Might Be Over-Engineered

In applications with no chemical exposure, low mechanical stress, and infrequent use, the advanced benefits of PTFE may not justify the cost.

For simple, non-critical tasks, a less expensive alternative could be the more practical and economical choice.

Making the Right Choice for Your Application

To determine if PTFE is the right economic choice, you must evaluate the operational demands of your specific environment.

- If your primary focus is minimizing long-term costs in a harsh environment: PTFE is almost always the more cost-effective solution due to its superior longevity.

- If your primary focus is the lowest possible initial purchase price for a low-stress application: A less durable, conventional material may be sufficient and more economical.

- If your primary focus is ensuring safety and compliance in sensitive industries (e.g., food-grade): PTFE's inertness and FDA compliance often make it a necessary and superior choice.

Ultimately, choosing PTFE is an investment in operational stability and predictable, lower lifetime costs.

Summary Table:

| Factor | PTFE Shovels | Conventional Alternatives |

|---|---|---|

| Initial Cost | Higher | Lower |

| Service Life | Long-lasting | Shorter |

| Replacement Frequency | Low | High |

| Chemical Resistance | Excellent | Limited |

| Impact on Downtime | Minimal | Significant |

Ready to reduce your long-term operational costs with high-performance PTFE components?

At KINTEK, we specialize in manufacturing precision PTFE components—including seals, liners, labware, and custom parts—for the semiconductor, medical, laboratory, and industrial sectors. Our solutions are engineered for durability and reliability, helping you minimize downtime and replacement expenses.

Whether you need prototypes or high-volume orders, we deliver custom fabrication tailored to your exact requirements.

Contact us today to discuss how our PTFE expertise can optimize your operations and total cost of ownership.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Scrapers and Shovels for Demanding Applications

- PTFE Chemical Solvent Sampling Spoon

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability