The most common symptoms of a leaking PTFE butterfly valve are visible fluid escaping from the valve body or continued fluid flow downstream even when the valve is fully closed. Operational issues, such as the valve becoming stiff or difficult to turn, can also be an early indicator of a developing leak.

A leaking PTFE butterfly valve will manifest its failure in one of two ways: an external leak that is visible to the eye, or an internal leak where the valve fails to create a proper seal, allowing fluid to pass through.

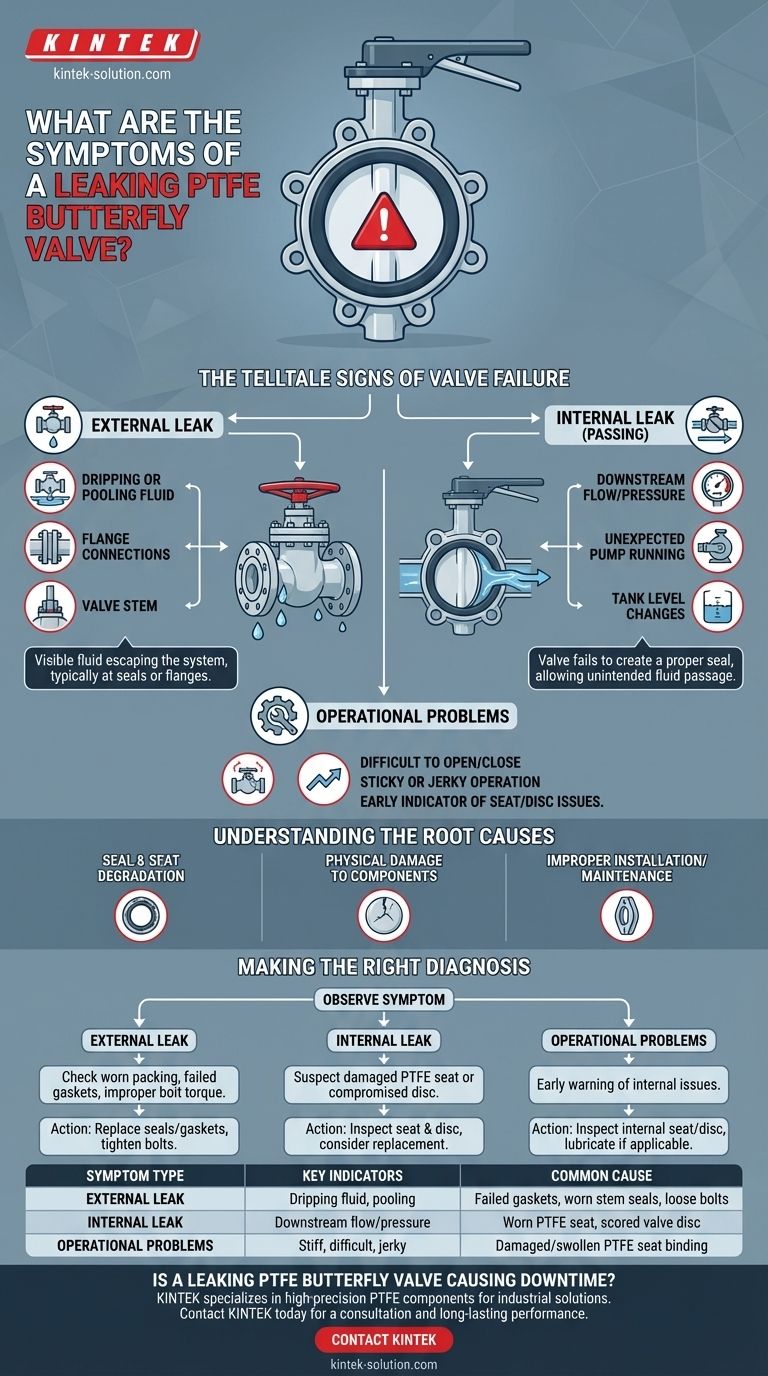

The Telltale Signs of Valve Failure

Diagnosing a valve issue correctly begins with accurately identifying the symptoms. Leaks can be broadly categorized as external, internal, or operational, each pointing to different potential root causes.

Symptom 1: External Leaks

An external leak means fluid is escaping the confines of the piping system and is often the most obvious sign of a problem.

You may see dripping or pooling liquid around the valve body itself. This is a clear indication that the process fluid is breaching a seal.

Look closely at the flange connections where the valve bolts to the pipe, or around the valve stem where it exits the top of the body. These are common failure points.

Symptom 2: Internal Leaks (Passing)

An internal leak occurs when the valve's disc and PTFE seat no longer create a bubble-tight seal. This is often called a "passing" valve.

The primary symptom is unintended flow or pressure in the downstream section of the pipe when the valve is in the fully closed position.

You might notice a downstream pump running unexpectedly or a tank level slowly changing when it should be static. This indicates the valve is not providing complete isolation.

Symptom 3: Operational Problems

Sometimes, a change in how the valve operates is the first warning sign before a significant leak develops.

If the valve becomes unusually difficult to open or close, it can indicate that the PTFE seat has been damaged, swollen, or is binding against the disc.

A "sticky" or jerky operation suggests the internal components are not moving smoothly, which can quickly lead to a torn seat and a subsequent leak.

Understanding the Root Causes

Identifying the symptom is only the first step. Understanding the underlying cause is critical to implementing a lasting solution and preventing recurrence.

Cause 1: Seal and Seat Degradation

The PTFE seat is the most common point of failure. Over time, it can become worn, scored, or chemically degraded, compromising its ability to seal against the disc.

Gaskets used at the flange connections can also fail due to age, improper material selection, or incorrect compression, leading to external leaks.

Cause 2: Physical Damage to Components

A crack or score on the valve disc creates a path for fluid to bypass the seat, causing an internal leak. This can be caused by abrasive media or water hammer.

Damage to the valve body itself, while less common, can lead to significant external leaks and is often a critical safety concern.

Cause 3: Improper Installation or Maintenance

Loose or improperly torqued bolts at the flange connections are a frequent cause of external leaks. This allows a gap to form between the valve and the pipe flange.

Misalignment of the valve during installation can put uneven stress on the PTFE seat, leading to premature wear and failure.

Making the Right Diagnosis

Based on what you observe, you can determine the most likely course of action for your system.

- If you see an external leak around the stem or flanges: Your immediate focus should be on worn packing, failed gaskets, or improper bolt torque.

- If you suspect an internal leak (passing fluid): The most probable cause is a damaged or worn PTFE seat or a compromised valve disc.

- If the valve is stiff or difficult to operate: This is an early warning sign that the internal seat or disc may be compromised, requiring inspection before a major leak occurs.

By correctly identifying the symptoms, you can move from reacting to a failure to proactively addressing its root cause.

Summary Table:

| Symptom Type | Key Indicators | Common Cause |

|---|---|---|

| External Leak | Dripping fluid, pooling around valve body or flanges | Failed gaskets, worn stem seals, loose bolts |

| Internal Leak (Passing) | Downstream flow/pressure when valve is closed | Worn or damaged PTFE seat, scored valve disc |

| Operational Problems | Valve is stiff, difficult to turn, or jerky | Damaged or swollen PTFE seat binding against disc |

Is a leaking PTFE butterfly valve causing downtime or process issues in your facility? KINTEK specializes in manufacturing high-precision, durable PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you need a reliable replacement part or a custom-fabricated solution from prototype to high-volume production, our expertise ensures a perfect seal and long-lasting performance. Contact KINTEK today for a consultation and let us help you solve your valve leak problems for good.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry