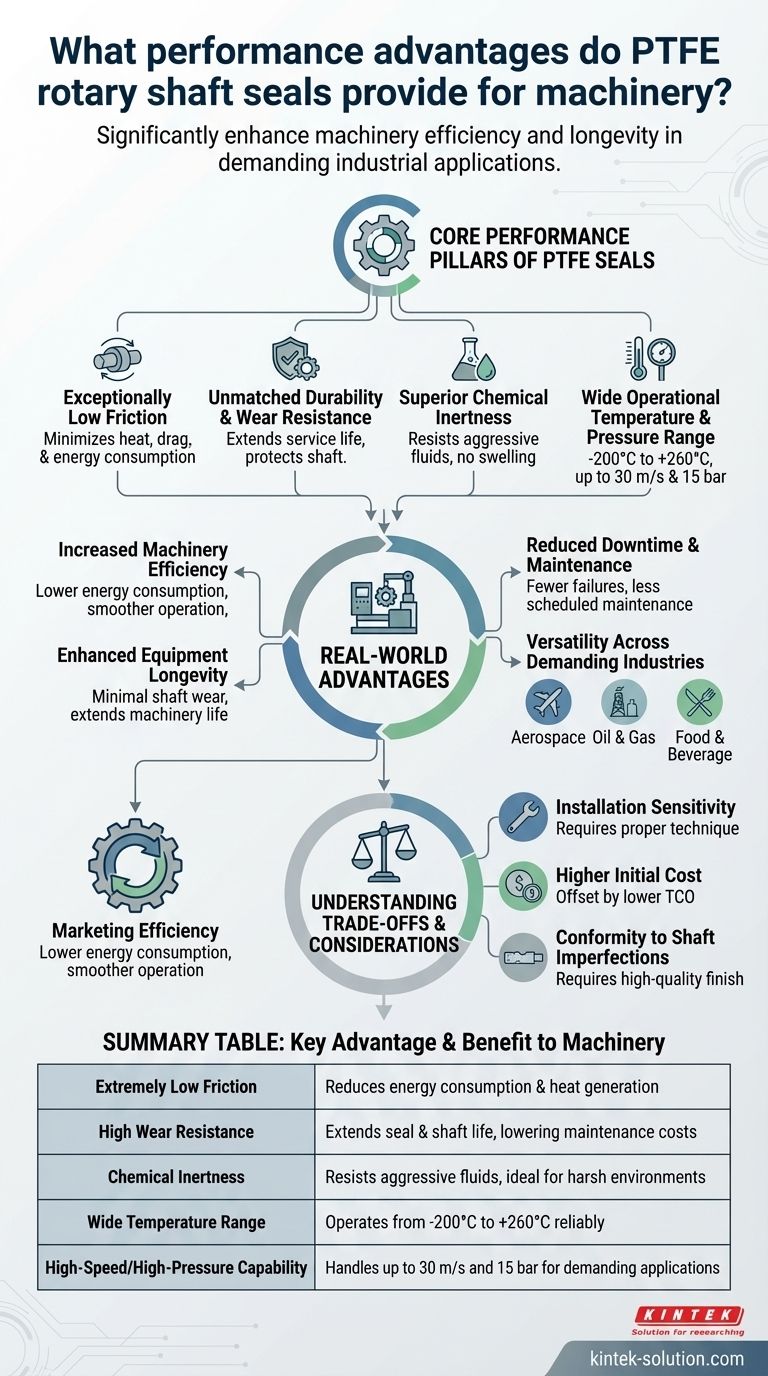

In demanding industrial applications, the performance advantages of Polytetrafluoroethylene (PTFE) rotary shaft seals are significant and multifaceted. They enable machinery to operate at peak efficiency by providing a unique combination of extremely low friction, high wear resistance, and robust tolerance for a wide range of temperatures, pressures, and aggressive chemicals, directly leading to longer equipment life and reduced downtime.

The core advantage of PTFE rotary shaft seals is not a single feature, but their unique ability to maintain sealing integrity under extreme operational conditions where traditional elastomer seals would fail. This translates directly into less energy consumption, reduced shaft wear, and significantly longer service intervals.

The Core Performance Pillars of PTFE Seals

Understanding the fundamental properties of PTFE is key to appreciating its impact on machinery performance. These seals are engineered to solve the most common points of failure associated with conventional seals.

Exceptionally Low Friction

PTFE possesses an extremely low coefficient of friction. This property is critical as it drastically reduces the rotational drag on the shaft.

This low friction minimizes heat generation, reduces energy consumption, and eliminates "stick-slip" behavior, ensuring smoother and more efficient operation.

Unmatched Durability and Wear Resistance

The low friction of PTFE directly contributes to its high wear resistance. Less friction means less abrasive force on both the seal lip and the shaft surface.

This results in a significantly longer service life for the seal and, just as importantly, protects the shaft from grooving and damage, which lowers overall maintenance costs.

Superior Chemical Inertness

PTFE is chemically inert, meaning it is non-reactive with the vast majority of industrial chemicals and aggressive fluids.

This makes PTFE seals an ideal choice for applications in industries like oil and gas or chemical processing, where they maintain their integrity without swelling, degrading, or failing.

Wide Operational Temperature Range

PTFE seals can operate reliably across an exceptionally broad temperature spectrum, from as low as -200°C to as high as +260°C (-328°F to +500°F).

This thermal stability allows them to be used in everything from cryogenic applications to high-temperature processing where standard rubber seals would become brittle or melt.

High-Speed and High-Pressure Capability

These seals are engineered to perform under demanding dynamic conditions. They can handle surface speeds up to 30 m/s and pressures up to 15 bar (217 psi) or more, depending on the design.

This capability allows machinery to be run faster and under greater loads without compromising sealing effectiveness.

How These Properties Translate to Real-World Advantages

The technical characteristics of PTFE seals deliver tangible benefits in efficiency, cost, and reliability for any machinery they are installed in.

Increased Machinery Efficiency

By minimizing frictional losses, PTFE seals reduce the amount of energy required to turn the shaft. This improvement in mechanical efficiency can lead to lower energy consumption over the life of the equipment.

Reduced Downtime and Maintenance

The combination of high wear resistance and self-lubricating properties (allowing for dry running in some cases) means these seals fail far less frequently than their elastomer counterparts.

Longer service intervals directly translate to less scheduled and unscheduled downtime, boosting productivity and lowering labor costs.

Enhanced Equipment Longevity

Because PTFE seals cause minimal wear to the shaft itself, they help preserve the life of critical and expensive machinery components. This protection against shaft damage is a major factor in extending the overall operational life of the equipment.

Versatility Across Demanding Industries

PTFE seals are indispensable in sectors with harsh operating environments.

- Aerospace: Valued for low outgassing and temperature resistance.

- Oil & Gas: Chosen for chemical inertness against corrosive fluids.

- Food & Beverage: Used for their non-reactive, FDA-approved properties.

Understanding the Trade-offs and Considerations

While highly effective, PTFE seals are not a universal solution. Their unique properties come with specific considerations that are important for successful implementation.

Installation Sensitivity

PTFE is a less flexible material than traditional elastomers like nitrile rubber. This makes proper installation technique critical. An improperly installed PTFE seal can be damaged, leading to premature leakage and failure.

Higher Initial Cost

The advanced material and manufacturing processes mean PTFE seals typically have a higher upfront purchase price than standard elastomeric seals. This cost is intended to be offset by a lower total cost of ownership through reduced maintenance and longer life.

Conformity to Shaft Imperfections

Due to their relative stiffness, PTFE seals are less forgiving of shaft surface imperfections or significant runout compared to softer, more pliable rubber seals. Optimal performance requires a high-quality shaft finish.

Making the Right Choice for Your Application

Selecting the correct seal material is a critical engineering decision based on the specific demands of your machinery.

- If your primary focus is operating in extreme temperatures or with aggressive chemicals: PTFE seals are often the only viable solution due to their unparalleled thermal stability and chemical inertness.

- If your primary focus is maximizing speed and minimizing friction: The low friction coefficient of PTFE allows for higher rotational speeds and reduces energy loss, making it ideal for high-performance machinery.

- If your primary focus is reducing long-term maintenance and downtime: The exceptional wear resistance and long service life of PTFE seals can justify their initial cost by significantly extending maintenance intervals.

Ultimately, choosing a PTFE seal is an investment in operational reliability, particularly when standard seals have reached their functional limits.

Summary Table:

| Key Advantage | Benefit to Machinery |

|---|---|

| Extremely Low Friction | Reduces energy consumption and heat generation |

| High Wear Resistance | Extends seal and shaft life, lowering maintenance costs |

| Chemical Inertness | Resists aggressive fluids, ideal for harsh environments |

| Wide Temperature Range | Operates from -200°C to +260°C reliably |

| High-Speed/High-Pressure Capability | Handles up to 30 m/s and 15 bar for demanding applications |

Upgrade your machinery with high-performance PTFE seals from KINTEK.

Our precision-engineered PTFE components—including seals, liners, and labware—are designed for the semiconductor, medical, laboratory, and industrial sectors. We specialize in custom fabrication from prototypes to high-volume orders, ensuring your equipment achieves maximum efficiency, longevity, and reliability.

Contact us today to discuss how our PTFE solutions can solve your toughest sealing challenges → #ContactForm

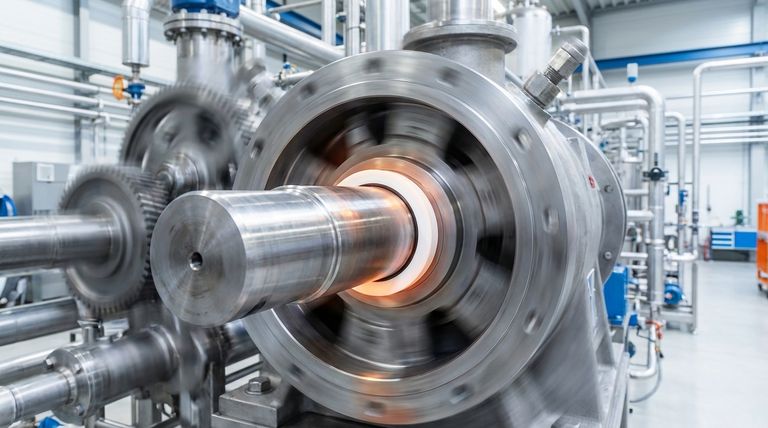

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs