PTFE compensators are most commonly used in the chemical processing, petrochemical, power generation, and pharmaceutical industries. Their unique ability to handle aggressive chemicals and absorb system movement makes them essential for connecting sensitive equipment like reactors, pumps, and heat exchangers in demanding operational environments.

The core reason for using a PTFE compensator is not just the industry, but the specific operational challenge: safely managing movement, vibration, and thermal expansion in piping systems that transport highly corrosive, high-purity, or high-temperature media.

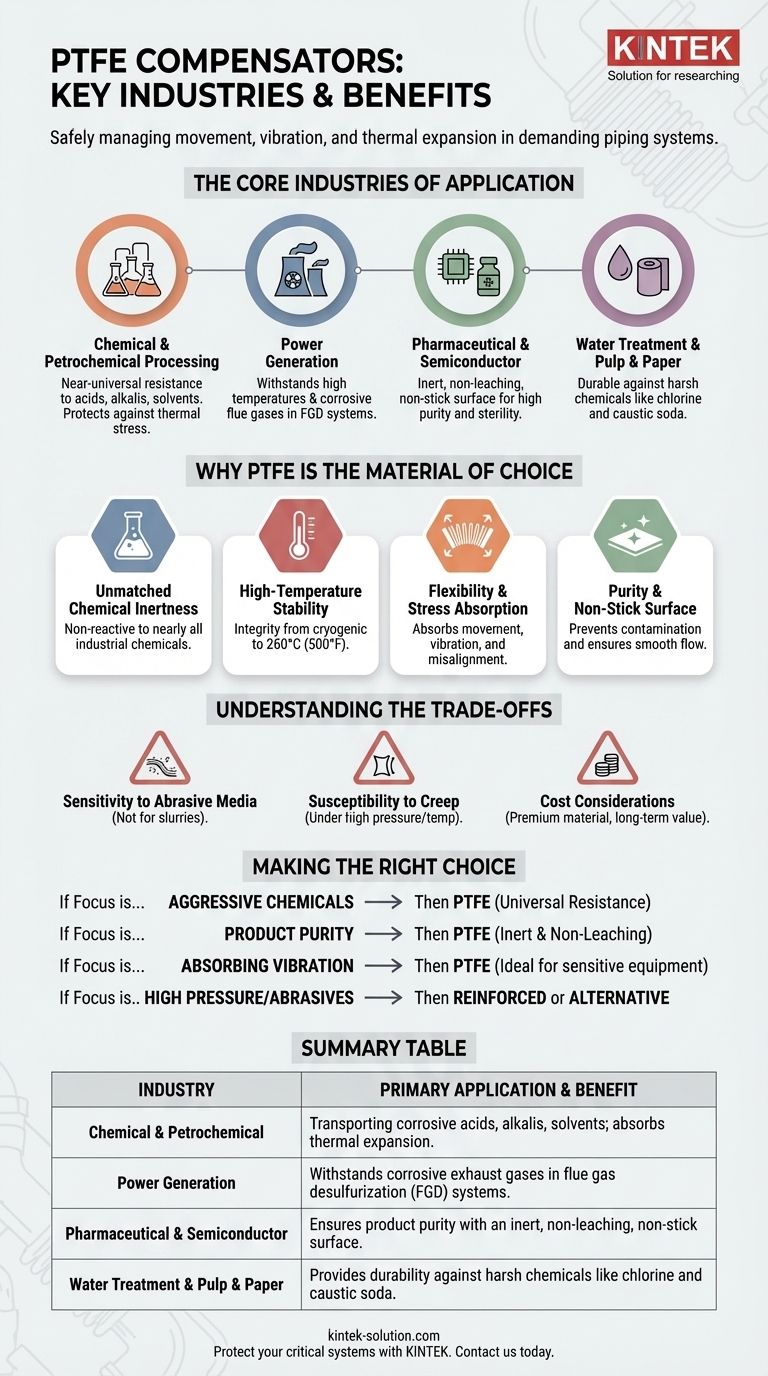

The Core Industries of Application

Polytetrafluoroethylene (PTFE) is a high-performance fluoropolymer prized for its remarkable properties. Compensators, also known as expansion joints, leverage these properties to solve critical engineering problems across several key sectors.

Chemical and Petrochemical Processing

This is the primary domain for PTFE compensators. These facilities handle a vast range of aggressive substances that would quickly degrade metal or rubber joints.

PTFE provides a near-universal solution for transporting corrosive acids, alkalis, and solvents. They are critical components for protecting expensive equipment from the stresses of thermal expansion and pump vibration.

Power Generation

Power plants, whether fossil fuel or other types, utilize complex chemical processes and manage high-temperature gases.

PTFE compensators are often found in flue gas desulfurization (FGD) systems and other ducting applications where they must withstand corrosive exhaust gases and significant temperature fluctuations.

Pharmaceutical and Semiconductor Manufacturing

In these industries, preventing contamination is as important as chemical resistance. The goal is to protect the product from the equipment, not just the other way around.

PTFE is exceptionally inert and non-leaching, ensuring that no impurities are introduced into the high-purity media. Its smooth, non-stick surface also inhibits bacterial growth, making it ideal for sterile processes.

Water Treatment and Pulp & Paper

These industries rely on harsh chemicals like chlorine, caustic soda, and various acids to treat water or process pulp.

PTFE-lined components and compensators provide the long-term durability needed to handle these chemicals without the constant replacement required for less robust materials.

Why PTFE is the Material of Choice

The widespread use of PTFE is not accidental. It stems from a combination of properties that make it uniquely suited for these challenging applications.

Unmatched Chemical Inertness

PTFE is non-reactive to nearly every chemical, acid, and solvent used in industry. This makes it the default material for any application involving a "cocktail" of unknown or changing corrosive substances.

High-Temperature Stability

PTFE maintains its integrity and properties across a very wide temperature range. It can handle processes from cryogenic levels up to 260°C (500°F), a range that many other flexible materials cannot tolerate.

Flexibility and Stress Absorption

The fundamental purpose of a compensator is to absorb movement. PTFE can be formed into flexible bellows that effectively absorb thermal expansion, mechanical vibration, and pipe misalignment, protecting rigid pipework and connected equipment from catastrophic failure.

Purity and Non-Stick Surface

The famous non-stick quality of PTFE (known commercially as Teflon) is critical for purity. It prevents materials from sticking to the pipe walls, ensuring smooth flow and making systems easier to clean, which is a vital requirement in the pharmaceutical and food industries.

Understanding the Trade-offs

While incredibly capable, PTFE is not a universal solution. An objective assessment requires understanding its limitations.

Sensitivity to Abrasive Media

PTFE is a relatively soft material. It is not well-suited for carrying abrasive slurries, which can quickly wear away the liner and lead to premature failure.

Susceptibility to Creep

Under sustained high pressure and temperature, PTFE can be prone to "creep," or gradual deformation. For this reason, high-pressure applications often require compensators with metallic reinforcement rings.

Cost Considerations

PTFE is a premium performance material, and its cost reflects that. However, this initial investment is almost always justified by its extended service life and the prevention of costly downtime and equipment failure in environments where lesser materials would fail rapidly.

Making the Right Choice for Your Goal

Selecting the right material is about matching its properties to your primary operational challenge.

- If your primary focus is handling aggressive chemicals: PTFE's near-universal chemical resistance makes it the default choice for corrosive acids, bases, and solvents.

- If your primary focus is product purity: PTFE's inert, non-leaching surface is essential for applications in pharmaceuticals, food processing, and semiconductor manufacturing.

- If your primary focus is absorbing system vibration and movement: A PTFE compensator is ideal for protecting sensitive equipment like pumps and reactors from the stresses of thermal expansion and mechanical vibration.

- If you are dealing with high pressure or abrasive materials: You must consider reinforced PTFE designs or alternative materials, as standard PTFE can be susceptible to wear and deformation under these conditions.

Ultimately, choosing a PTFE compensator is an investment in system reliability and safety in your most demanding applications.

Summary Table:

| Industry | Primary Application & Benefit |

|---|---|

| Chemical & Petrochemical | Transporting corrosive acids, alkalis, and solvents; absorbs thermal expansion. |

| Power Generation | Withstands corrosive exhaust gases in flue gas desulfurization (FGD) systems. |

| Pharmaceutical & Semiconductor | Ensures product purity with an inert, non-leaching, non-stick surface. |

| Water Treatment & Pulp & Paper | Provides durability against harsh chemicals like chlorine and caustic soda. |

Protect your critical systems with precision-engineered PTFE components from KINTEK.

Does your application in the semiconductor, medical, laboratory, or industrial sector involve handling corrosive chemicals, ensuring high purity, or managing system vibration? KINTEK specializes in manufacturing high-performance PTFE components—including custom compensators, seals, liners, and labware—designed to meet the exacting demands of your specialized industry.

We offer custom fabrication from prototypes to high-volume orders, ensuring you get a reliable, long-lasting solution that prevents costly downtime.

Contact KINTEK today to discuss your specific requirements and let our expertise enhance the safety and reliability of your operations.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability