From a practical installation standpoint, PTFE compensators offer significant advantages over traditional metal alternatives. Their core benefits stem directly from their material properties: they are fundamentally lightweight, flexible, and more adaptable, which simplifies the entire process from transport to final assembly.

The primary installation advantage of PTFE compensators is not a single feature, but a combination of low weight and high flexibility. This directly translates into reduced labor requirements, simpler equipment needs, and faster, safer on-site handling.

The Core Factors Driving Installation Efficiency

To understand why PTFE compensators are easier to install, we must look at the specific physical characteristics that differentiate them from their rigid, bulky metal counterparts.

Reduced Weight and Manual Handling

Metal expansion joints are, by nature, heavy and cumbersome. Their installation often requires cranes, hoists, or other heavy lifting equipment, along with a larger crew for safe maneuvering.

PTFE compensators are dramatically lighter. This allows for easier transportation to the installation site and manual handling by one or two technicians, significantly reducing complexity and enhancing worker safety.

Inherent Flexibility and Adaptability

Piping systems are rarely perfectly aligned. Metal compensators are rigid and demand near-perfect flange alignment, which can lead to time-consuming adjustments and stress on the system.

PTFE, being a flexible polymer, can easily accommodate minor axial, lateral, or angular misalignments. This inherent "give" simplifies the connection process, reduces the need for precise field adjustments, and ensures a lower-stress fit.

Simplified Sealing and Tolerances

The material properties of PTFE allow it to be molded into complex shapes with tight tolerances. During installation, this means the compensator can better conform to the flange face.

This adaptability helps create a reliable seal even with minor imperfections on the flange surface, reducing the potential for leaks and the need for excessive re-torquing.

Understanding the Trade-offs

While the installation benefits are clear, an objective decision requires acknowledging the trade-offs associated with any material choice.

Susceptibility to Handling Damage

Metal is inherently robust and resistant to external impacts or rough handling.

PTFE compensators require more care during transport and installation. Scratches, gouges, or cuts from tools can compromise the sealing surface or the liner's integrity, so proper handling protocols are essential.

Pressure and Temperature Constraints

Different materials excel in different environments. While modern PTFE is highly durable, certain high-pressure or extreme-temperature applications may still necessitate specialized metal alloys.

The operational environment, not just the installation process, must be the final arbiter in material selection. A component that is easy to install but fails under operational stress is the wrong choice.

The Importance of Correct Torquing

The flexibility that makes PTFE easy to install also makes it susceptible to damage from over-torquing. Overtightening bolts can crush the PTFE, leading to premature failure.

Installation crews must follow the manufacturer's specific torque values precisely, unlike the more forgiving brute-force approach that can sometimes be used with metal flanges.

How to Apply This to Your Project

Your final decision should be based on the specific priorities and constraints of your system and project timeline.

- If your primary focus is rapid installation and minimizing labor costs: PTFE is the superior choice due to its light weight, flexibility, and ease of manual handling.

- If you are dealing with an existing system with slight piping misalignment: PTFE's adaptability offers a significant advantage, reducing the need for costly and time-consuming field corrections.

- If your system operates at extreme pressures or is subject to external impact risk: A robust metal compensator may be necessary, even if it requires a more complex and resource-intensive installation process.

Ultimately, choosing the right compensator means viewing installation efficiency as a critical component of total system performance and cost.

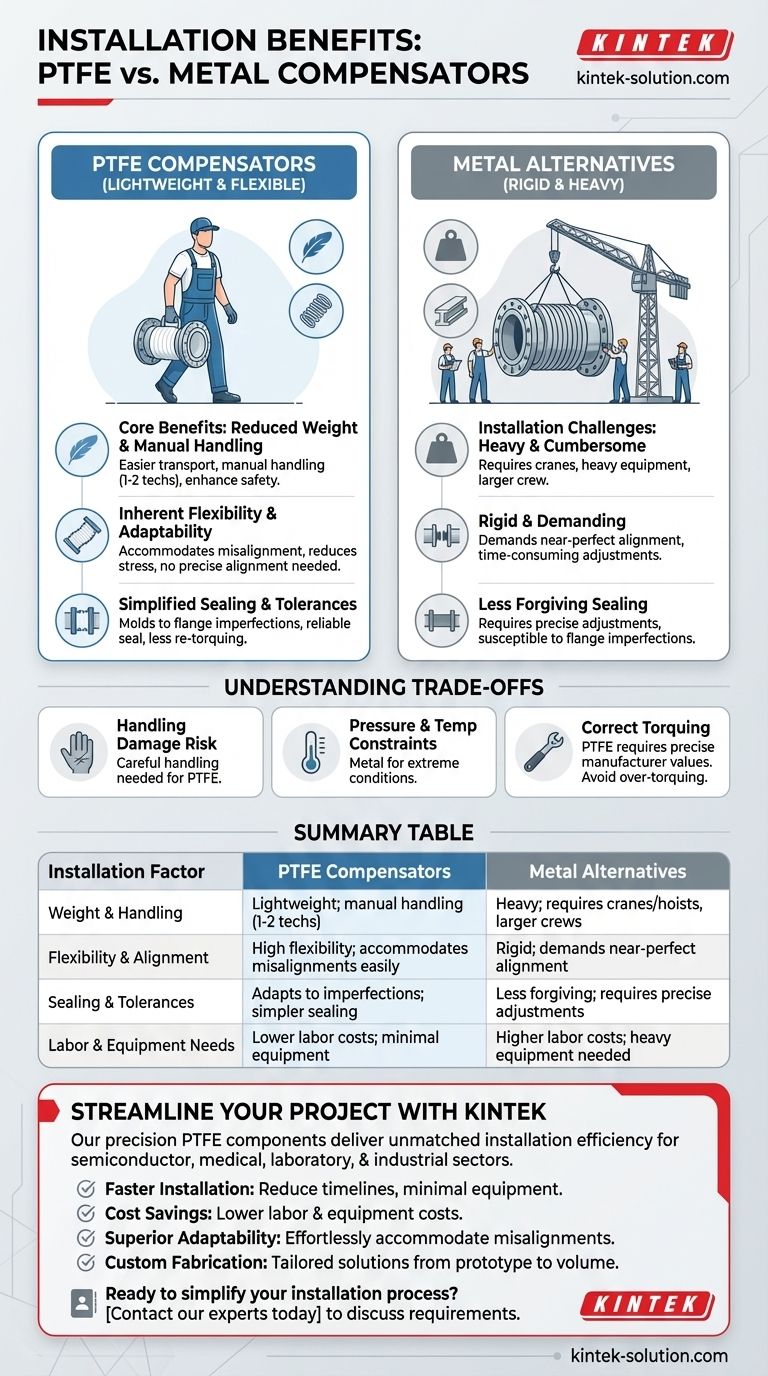

Summary Table:

| Installation Factor | PTFE Compensators | Metal Alternatives |

|---|---|---|

| Weight & Handling | Lightweight; manual handling by 1-2 technicians | Heavy; requires cranes/hoists and larger crews |

| Flexibility & Alignment | High flexibility; accommodates misalignments easily | Rigid; demands near-perfect flange alignment |

| Sealing & Tolerances | Adapts to flange imperfections; simpler sealing | Less forgiving; requires precise adjustments |

| Labor & Equipment Needs | Lower labor costs; minimal equipment | Higher labor costs; heavy equipment needed |

Streamline your next piping project with KINTEK's precision PTFE components.

Our PTFE compensators, seals, and liners are engineered for the semiconductor, medical, laboratory, and industrial sectors to deliver unmatched installation efficiency. By choosing KINTEK, you benefit from:

- Faster Installation: Reduce project timelines with lightweight, flexible components that require minimal equipment and manpower.

- Cost Savings: Lower labor and equipment costs from transport to final assembly.

- Superior Adaptability: Accommodate existing system misalignments effortlessly, avoiding costly field corrections.

- Custom Fabrication: We provide tailored solutions from prototypes to high-volume orders, ensuring a perfect fit for your specific application.

Ready to simplify your installation process and enhance system performance? Contact our experts today to discuss your project requirements and discover the right PTFE solution for you.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions