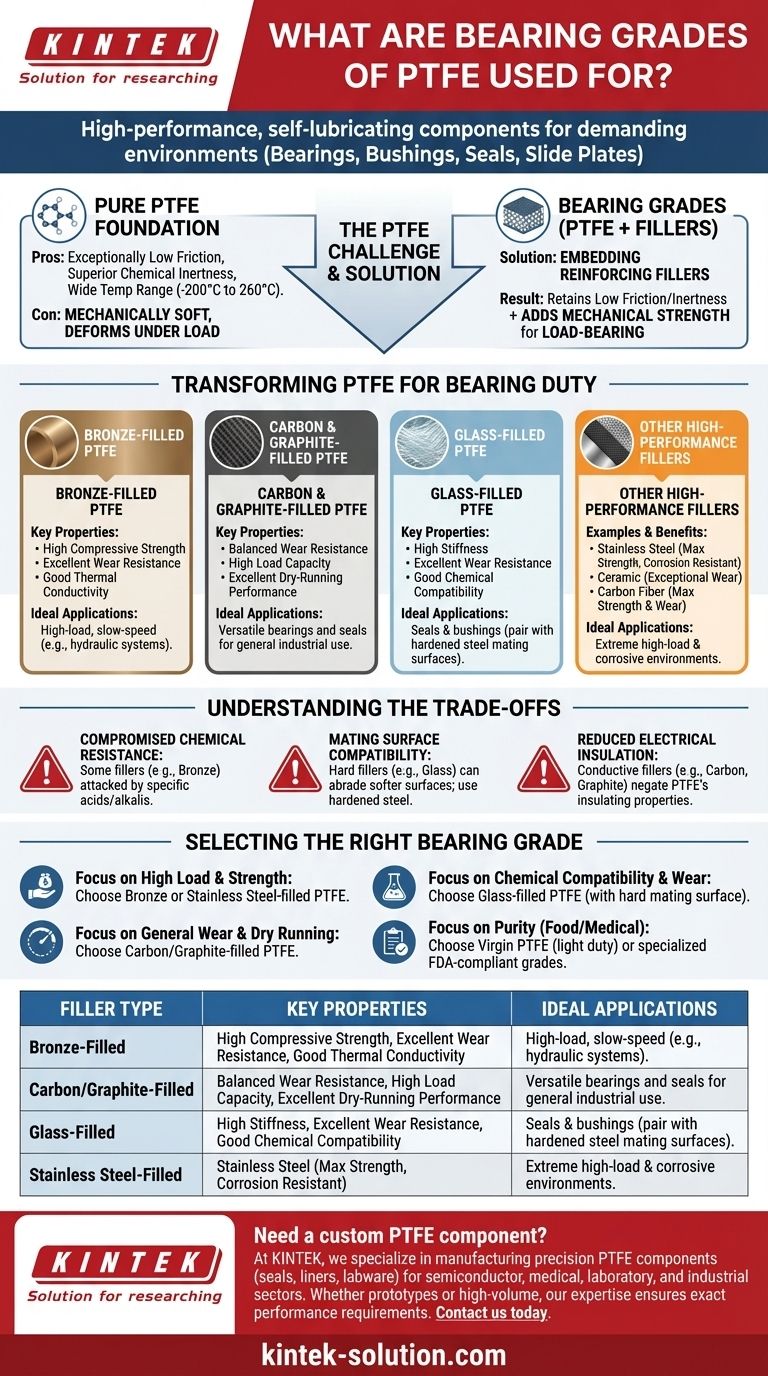

In short, bearing grades of PTFE are used to create high-performance, self-lubricating components for demanding environments. They are engineered for applications like bearings, bushings, seals, and slide plates where extremely low friction, chemical resistance, and high-temperature tolerance are required. These specialized grades are compounds, where fillers like carbon, bronze, or glass are added to pure PTFE to drastically improve its strength and resistance to wear and deformation under load.

The core challenge with pure Polytetrafluoroethylene (PTFE) is that it is mechanically soft and deforms under pressure. Bearing grades solve this by embedding reinforcing fillers into the PTFE matrix, creating a composite material that retains PTFE's signature low friction and chemical inertness while adding the mechanical strength necessary for load-bearing applications.

Why PTFE is the Foundation for Performance Bearings

Before adding fillers, it's essential to understand why pure PTFE is such an attractive base material. Its fundamental properties solve several common engineering problems, but its softness is a critical limitation for structural parts.

Exceptionally Low Coefficient of Friction

PTFE has one of the lowest coefficients of friction of any solid material known. This "slipperiness" is its most famous characteristic.

For bearing applications, this means machinery can operate with less energy loss and without the need for external liquid lubricants, which can be a point of failure or a source of contamination.

Superior Chemical Inertness

PTFE is non-reactive to nearly all industrial chemicals, acids, and bases. This makes it an ideal choice for components used in corrosive environments.

This is critical in chemical processing equipment, medical devices, and food production, where components are exposed to aggressive substances or require stringent cleaning protocols.

Wide Operating Temperature Range

The material remains stable and functional across an impressive temperature spectrum, from cryogenic lows to highs of around 260°C (500°F). This thermal stability allows it to perform reliably where many other polymers would fail.

The Role of Fillers: Transforming PTFE for Bearing Duty

Virgin PTFE, while excellent in many ways, will deform or "creep" under sustained load. Fillers are added to create a composite that dramatically improves mechanical properties, turning a soft polymer into a robust engineering material.

Bronze-Filled PTFE

Bronze powder is a common filler that significantly increases compressive strength and thermal conductivity, allowing heat to dissipate from the bearing surface more effectively.

This grade offers excellent wear resistance and is well-suited for high-load, slow-speed applications. It is widely used in hydraulic systems.

Carbon and Graphite-Filled PTFE

This combination offers a balanced set of properties, including good wear resistance, high load-bearing capacity, and excellent performance in dry-running conditions.

Graphite lowers the coefficient of friction even further, while carbon improves hardness and load strength. This makes it a versatile, all-around choice for many bearing and seal applications.

Glass-Filled PTFE

Adding glass fibers dramatically increases stiffness and wear resistance compared to virgin PTFE. It also has excellent chemical compatibility.

This grade is often used for seals and bushings. However, the glass fibers can be abrasive to softer mating surfaces like aluminum, so it performs best against hardened steel.

Other High-Performance Fillers

For extreme conditions, other fillers are used. Stainless steel is added for high-load and corrosion-resistant applications. Ceramic provides exceptional wear resistance, and carbon fiber delivers maximum strength and wear performance.

Understanding the Trade-offs

Selecting a filled PTFE grade involves balancing competing properties. Enhancing one characteristic can sometimes compromise another.

Compromised Chemical Resistance

While the PTFE base remains inert, some fillers can be attacked by specific chemicals. Bronze-filled grades, for example, may not be suitable for use with certain acids or strong alkalis that would not affect pure PTFE.

Mating Surface Compatibility

The hardness that fillers provide to improve wear resistance can, in turn, wear down the mating surface (the shaft or plate). Glass-filled PTFE is a prime example; it should be paired with a hard material like stainless steel to prevent damage.

Reduced Electrical Insulation

Pure PTFE is an excellent electrical insulator. However, adding conductive fillers like carbon, graphite, or metal powders will negate this property. If electrical insulation is critical, a non-conductive filler like glass or ceramic is the only viable option.

Selecting the Right Bearing Grade for Your Application

Your choice of material should be driven directly by the primary demands of your design.

- If your primary focus is high load capacity and mechanical strength: Choose a bronze-filled or stainless steel-filled PTFE for their superior compressive strength.

- If your primary focus is general-purpose wear resistance in dry running conditions: Carbon/graphite-filled PTFE is an excellent, balanced choice that performs well across various applications.

- If your primary focus is chemical compatibility with improved wear: Glass-filled PTFE is often suitable, but you must ensure the mating surface is hard enough to resist abrasion.

- If your primary focus is purity for food or medical use: Virgin PTFE is often used for seals and light-duty bushings, though specialized, FDA-compliant filled grades are also available.

By understanding how fillers enhance PTFE's inherent properties, you can select a bearing material precisely engineered for your specific load, speed, and environmental challenges.

Summary Table:

| Filler Type | Key Properties | Ideal Applications |

|---|---|---|

| Bronze-Filled | High compressive strength, excellent wear resistance, good thermal conductivity | High-load, slow-speed applications (e.g., hydraulic systems) |

| Carbon/Graphite-Filled | Balanced wear resistance, high load capacity, excellent dry-running performance | Versatile bearings and seals for general industrial use |

| Glass-Filled | High stiffness, excellent wear resistance, good chemical compatibility | Seals and bushings (paired with hardened steel mating surfaces) |

| Stainless Steel-Filled | Maximum strength, corrosion resistance | Extreme high-load and corrosive environments |

Need a custom PTFE component for your demanding application? At KINTEK, we specialize in manufacturing precision PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you require prototypes or high-volume orders, our expertise in filled PTFE grades ensures your parts meet exact performance requirements. Contact us today to discuss your project and leverage our custom fabrication capabilities!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the main advantages of expanded PTFE gaskets? Superior Sealing Reliability vs. Pure PTFE

- What are the key benefits of PTFE oil seals? Superior Performance in Extreme Conditions

- How does a pneumatic actuator function in a PTFE pneumatic valve? A Guide to Automated Control

- What causes a PTFE butterfly valve to stick or become hard to operate? Diagnose and Fix Common Issues

- What is the coefficient of friction for PTFE? Mastering Low-Friction Material Selection

- How does tool selection affect PTFE surface finish? Achieve a Flawless Finish with the Right Tools

- What materials are processed into CNC PTFE parts? A Guide to Stock Shapes and Grades

- What are the key roles of PTFE rotary shaft seals in industrial applications? Ensure Reliability in Extreme Conditions