Choosing the right cutting tool is the single most critical decision when machining Polytetrafluoroethylene (PTFE). Unlike metals, PTFE's unique combination of softness, high thermal expansion, and poor heat conductivity makes it exceptionally sensitive to machining forces and temperature. Using an incorrect tool will not cut the material cleanly; it will push, deform, or even melt it, resulting in poor dimensional accuracy, burrs, and a ruined surface finish.

The core challenge in machining PTFE is not overcoming material hardness, but managing its softness and thermal sensitivity. Your tool selection is your primary method for controlling heat and mechanical stress, directly determining whether you achieve a clean, precise cut or a deformed, unusable part.

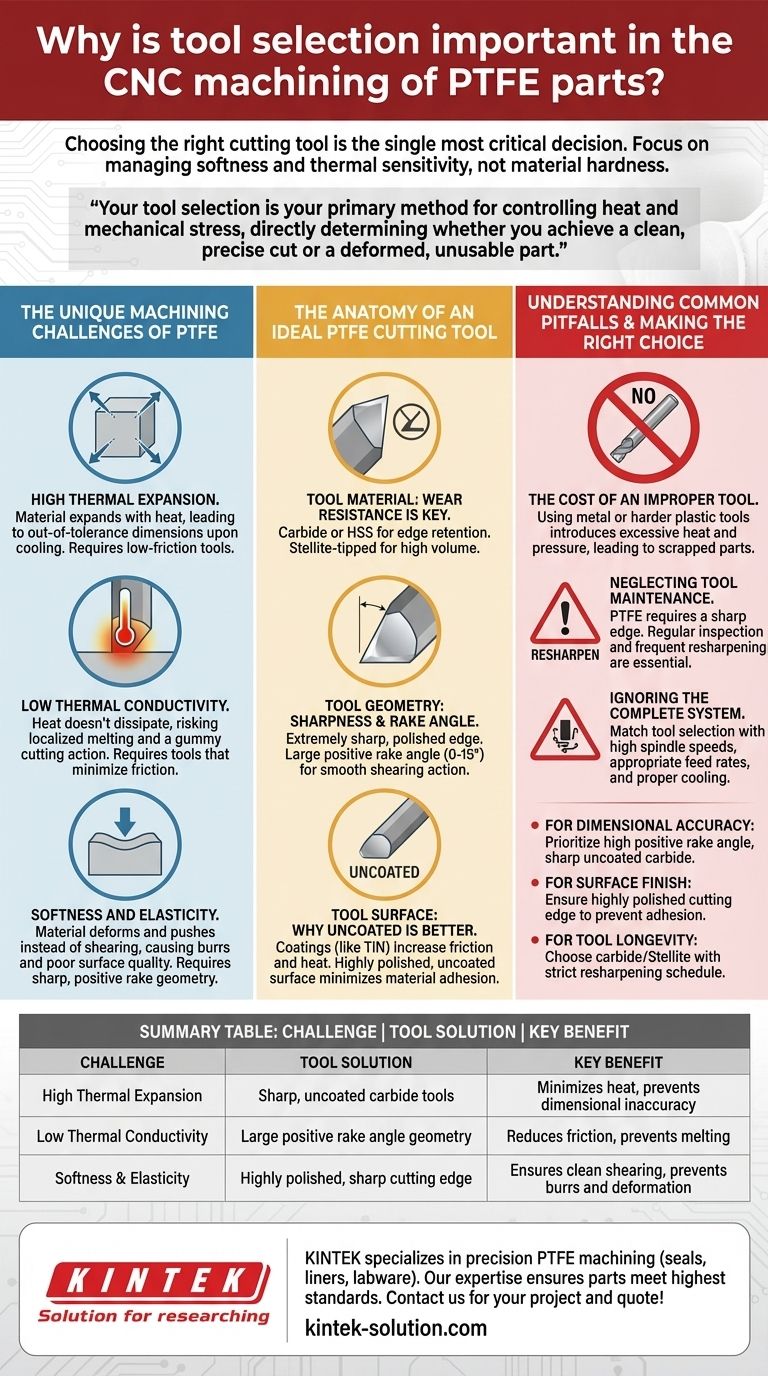

The Unique Machining Challenges of PTFE

To understand why tool selection is so paramount, we must first understand the material itself. PTFE does not behave like common plastics or metals during machining, presenting a distinct set of challenges.

High Thermal Expansion

PTFE has a very high coefficient of thermal expansion. Even a small amount of heat generated from cutting friction will cause the material to expand significantly.

This expansion during the machining process means the part will contract as it cools, often resulting in final dimensions that are out of tolerance. A proper tool minimizes friction and heat, mitigating this effect.

Low Thermal Conductivity

Compounding the problem, PTFE is an excellent thermal insulator. It does not dissipate heat away from the cutting edge effectively.

This concentrates heat right where the tool meets the material, increasing the risk of localized melting. This can lead to a "gummy" cutting action and material adhering to the tool, ruining the part and the tool's cutting edge.

Softness and Elasticity

PTFE is a soft material that can easily deform under pressure rather than being cut. A dull tool or one with improper geometry will push the material away instead of shearing it.

This pushing action is a primary cause of heavy burring, dimensional instability, and poor surface quality. The goal is to slice the material cleanly with minimal force.

The Anatomy of an Ideal PTFE Cutting Tool

An ideal tool for PTFE is designed to specifically address the challenges of heat, friction, and material deformation. Its characteristics are fundamentally different from tools used for harder materials.

Tool Material: Wear Resistance is Key

The cutting edge must remain exceptionally sharp. Carbide or High-Speed Steel (HSS) are the most common and effective choices due to their ability to hold a sharp edge.

For high-volume production, carbide or Stellite-tipped tools offer superior wear resistance, ensuring consistent performance over longer periods.

Tool Geometry: Sharpness and Rake Angle

The geometry of the cutting edge is crucial. Tools must have an extremely sharp, polished cutting edge to slice cleanly through the soft material.

A large positive rake angle, typically between 0 and 15 degrees, is essential. This geometry reduces cutting forces, minimizes friction, and promotes a smooth shearing action rather than a brute-force push.

Tool Surface: Why Uncoated is Better

In a departure from many metal-machining applications, uncoated tools are preferred for PTFE.

Coatings like Titanium Nitride (TiN) can increase the coefficient of friction, which generates more heat—the primary enemy in PTFE machining. A highly polished, uncoated tool surface minimizes friction and the potential for material to stick to the tool.

Understanding Common Pitfalls

Selecting the right tool is only the first step. Avoiding common mistakes is just as important for achieving consistent, high-quality results.

The Cost of an Improper Tool

Using a standard tool designed for metal or a harder plastic is the most frequent mistake. This immediately introduces excessive heat and cutting pressure, leading to scrapped parts, wasted material, and lost time.

Neglecting Tool Maintenance

Because sharpness is so critical, even the right tool will fail if its edge becomes dull. PTFE will not forgive a worn tool.

Regular inspection and frequent resharpening are not optional; they are a required part of the process to maintain the clean shearing action necessary for quality parts.

Ignoring the Complete System

The perfect tool cannot compensate for incorrect machining parameters. Tool selection must be paired with high spindle speeds and appropriate feed rates to ensure the tool is cutting effectively rather than rubbing against the material. Proper part fixturing and cooling are also essential components of a successful process.

Making the Right Choice for Your Project

Your specific goal will influence which tool characteristics you prioritize. Use these guidelines to inform your selection.

- If your primary focus is dimensional accuracy: Prioritize a tool with a very high positive rake angle and use sharp, uncoated carbide to minimize cutting pressure and heat-induced expansion.

- If your primary focus is surface finish: Ensure your tool has a highly polished cutting edge to prevent material adhesion and reduce friction to an absolute minimum.

- If your primary focus is tool longevity in production: Choose carbide or Stellite-tipped tools for their wear resistance, but implement a strict resharpening schedule to maintain the critical sharp edge.

Ultimately, treating PTFE with precision and selecting a tool designed for finesse—not force—is the key to unlocking successful results.

Summary Table:

| Challenge | Tool Solution | Key Benefit |

|---|---|---|

| High Thermal Expansion | Sharp, uncoated carbide tools | Minimizes heat, prevents dimensional inaccuracy |

| Low Thermal Conductivity | Large positive rake angle geometry | Reduces friction, prevents melting |

| Softness & Elasticity | Highly polished, sharp cutting edge | Ensures clean shearing, prevents burrs and deformation |

Struggling with PTFE part quality? The right tooling makes all the difference. KINTEK specializes in the precision machining of PTFE components (seals, liners, labware, etc.) for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in selecting and applying the optimal tooling for soft, thermally sensitive materials ensures your parts meet the highest standards for dimensional accuracy and surface finish. Let us handle your custom fabrication needs from prototypes to high-volume production.

Contact KINTEK today to discuss your PTFE machining project and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the main properties of PTFE that make it valuable as a sealing material? Discover the Ultimate Sealing Solution

- What environmental benefits do PTFE expansion joints provide? Achieve Sustainability and Compliance

- What are important installation tips for PTFE butterfly valves? Ensure a Leak-Free, Long-Lasting Seal

- How is Teflon used in the semiconductor industry? Essential for High-Purity Manufacturing

- How does the low friction coefficient of PTFE expansion bellows benefit fluid flow? Reduce Energy Use & Prevent Blockages

- What types of PTFE machined parts are commonly produced? Essential Components for Demanding Industries

- How do PTFE sheets enhance machinery durability and efficiency? Achieve Superior Performance & Lower Costs

- How does PTFE impregnated with silicone oil improve gland packing performance? Enhance Sealing with Low Friction