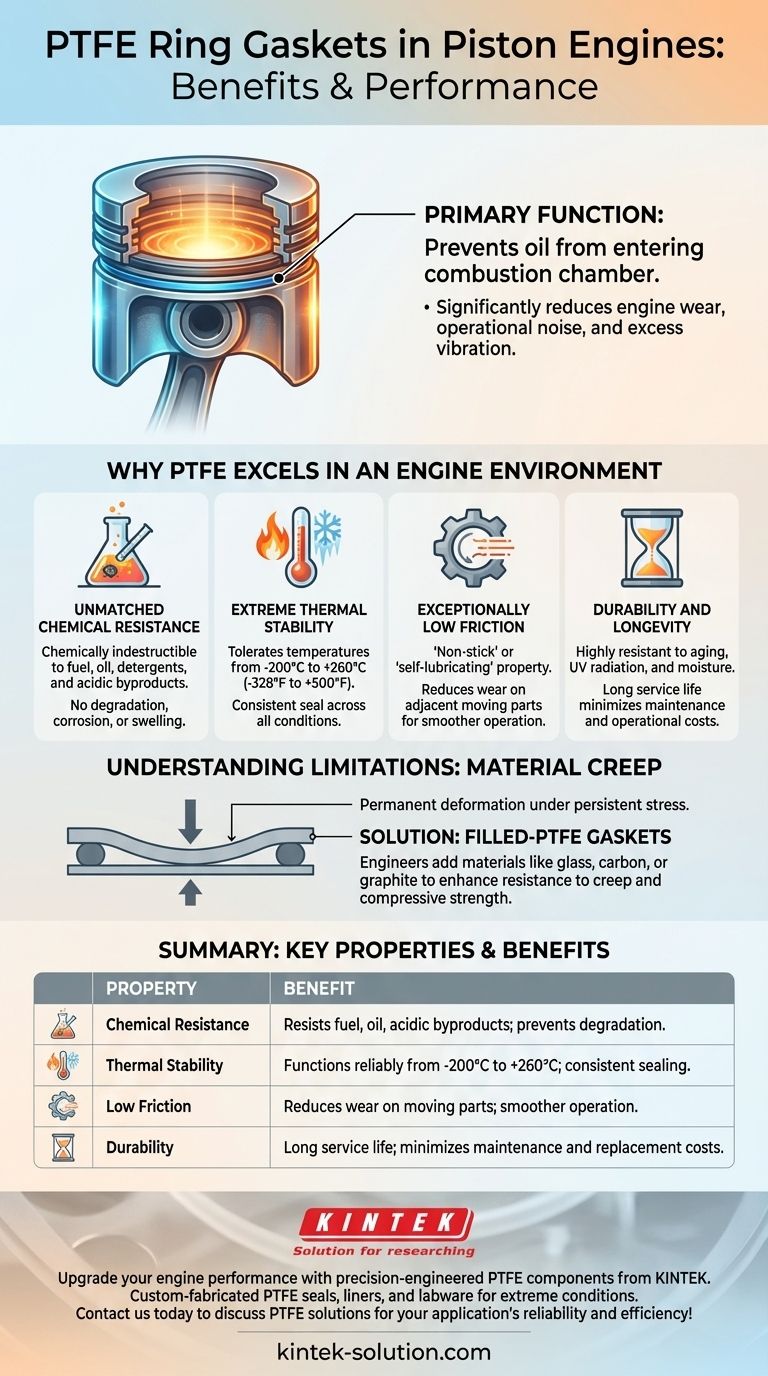

In a piston engine, PTFE ring gaskets serve a critical primary function: they prevent oil from entering the engine's combustion chamber. This single action leads to a cascade of benefits, most notably a significant reduction in engine wear, operational noise, and excess vibration.

The true value of PTFE in piston engines is not just its sealing capability, but its unique combination of material properties. Its extreme resistance to heat, chemicals, and friction allows it to maintain a reliable seal in one of the most hostile mechanical environments imaginable.

Why PTFE Excels in an Engine Environment

The interior of a piston engine is a punishing place, characterized by high temperatures, corrosive chemicals, and constant motion. PTFE (Polytetrafluoroethylene) is uniquely suited to survive and perform under these conditions due to its inherent molecular structure.

Unmatched Chemical Resistance

An engine's internal environment is a cocktail of aggressive substances, including fuel, oil, detergents, and acidic combustion byproducts.

PTFE is chemically indestructible to nearly all of these harsh substances. This inertness ensures the gasket will not degrade, corrode, or swell over time, maintaining its structural integrity and sealing capability.

Extreme Thermal Stability

Engine temperatures fluctuate dramatically, from cold starts to peak operating heat.

PTFE gaskets tolerate an exceptionally wide temperature range, typically from -200°C to +260°C (-328°F to +500°F). This stability prevents the material from becoming brittle in the cold or melting under high heat, ensuring a consistent seal across all operating conditions.

Exceptionally Low Friction

Pistons and other engine components are in constant, rapid motion.

PTFE has one of the lowest coefficients of friction of any solid material. This "non-stick" or "self-lubricating" property reduces wear and tear on adjacent moving parts, contributing to smoother operation and a longer engine life.

Durability and Longevity

Engine components are expected to last for thousands of hours of operation with minimal intervention.

PTFE is highly resistant to aging, ultraviolet radiation, and moisture. Its durability under repeated compression cycles means it has a very long service life, which minimizes maintenance requirements and reduces long-term operational costs.

Understanding the Limitations of PTFE

Despite its significant advantages, PTFE is not without its trade-offs. The most critical characteristic to understand is its tendency to "creep."

The Challenge of Material Creep

Creep is the tendency of a solid material to deform permanently under the influence of persistent mechanical stress.

For a gasket, this means that under constant pressure (like being bolted between two engine components), a pure PTFE ring can slowly flatten or "flow" out of position over time. This can eventually lead to a loss of sealing pressure and potential leaks.

Designing Around the Drawback

Engineers mitigate this by using filled-PTFE gaskets. By adding materials like glass, carbon, or graphite to the PTFE matrix, they enhance its resistance to creep and improve its compressive strength, while still retaining the material's core benefits.

Making the Right Choice for Your Application

Selecting the right gasket material requires balancing performance needs with material properties.

- If your primary focus is reliability in extreme conditions: PTFE's unparalleled chemical and thermal resilience makes it the superior choice for sealing in hostile engine environments.

- If your primary focus is managing high-stress, static loads: The creep potential of pure PTFE must be considered, and a filled-PTFE composite is often the necessary solution.

- If your primary focus is cost-effectiveness and longevity: PTFE's durability and long service life often justify any higher initial material cost by dramatically reducing maintenance and replacement cycles.

Ultimately, PTFE's unique properties make it an indispensable material for ensuring the reliability and efficiency of modern piston engines.

Summary Table:

| Property | Benefit in Piston Engines |

|---|---|

| Chemical Resistance | Resists fuel, oil, and acidic byproducts, preventing degradation. |

| Thermal Stability | Functions reliably from -200°C to +260°C, ensuring consistent sealing. |

| Low Friction | Reduces wear on moving parts, contributing to smoother operation. |

| Durability | Long service life minimizes maintenance and replacement costs. |

Upgrade your engine performance with precision-engineered PTFE components from KINTEK.

Whether you're in the semiconductor, medical, laboratory, or industrial sector, our custom-fabricated PTFE seals, liners, and labware are designed to withstand extreme conditions while reducing wear and operational costs. From prototypes to high-volume orders, we prioritize precision and durability to meet your specific needs.

Contact us today to discuss how our PTFE solutions can enhance your application's reliability and efficiency!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications